Rotary socket

A socket and rotating sleeve technology, applied in flexible/rotatable wire connectors, electrical components, circuits, etc., can solve the problems of complex assembly process, poor strength, and many structural parts, and achieve simple assembly process and high assembly efficiency. , the effect of less structural parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

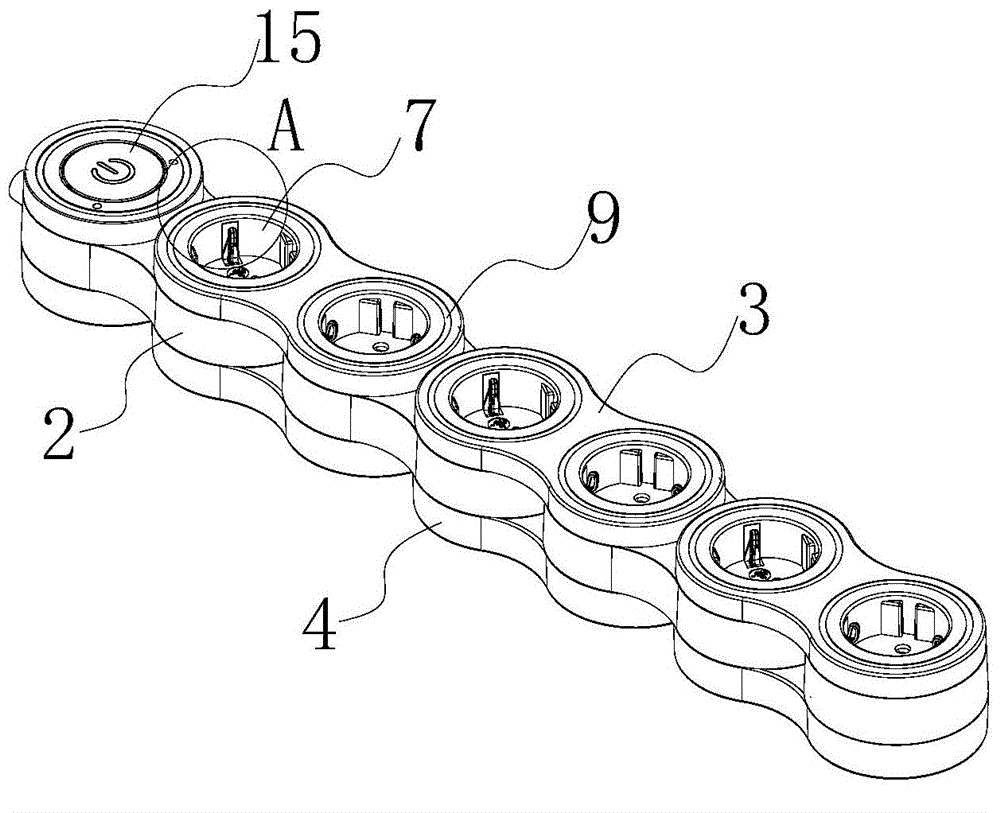

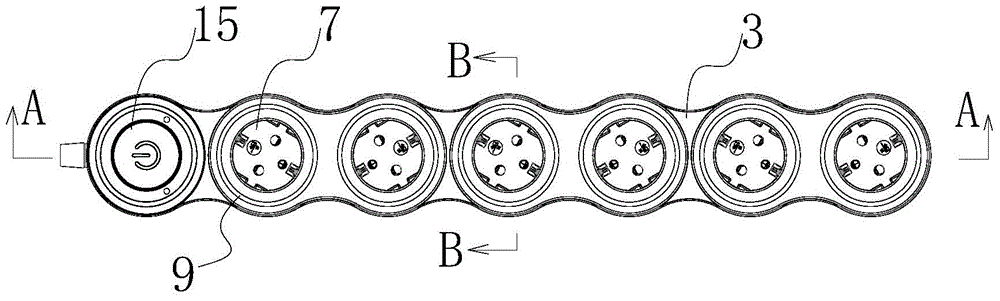

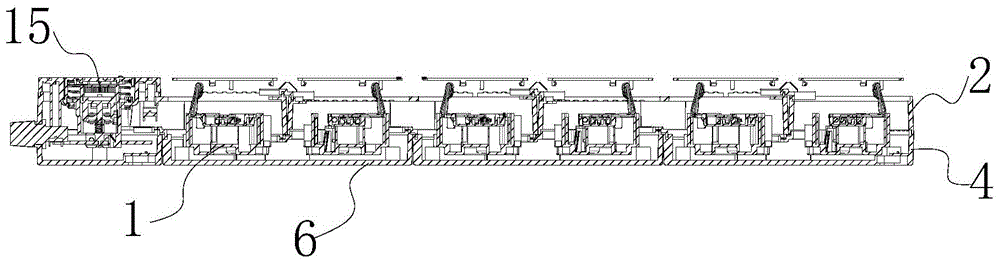

[0030] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

[0031] Such as Figure 1 to Figure 10 As shown, a rotary socket includes a housing and an electrical plug-in core 1 disposed in the housing. The housing includes one or more rotating sleeves 2, socket end caps 3 and bases 4, rotating sleeves 2, and socket end caps. 3 and the base 4 are in the shape of "8"; the end of the housing is provided with a control switch 15 connected to the core body 1 of the electrical plug-in in the rotating sleeve 2.

[0032] There are mounting holes 5 on both sides of the rotating sleeve 2, the socket end cover 3 is arranged above the rotating sleeve 2, the base 4 is arranged below the rotating sleeve 2, the upper and lower positions of the socket end cover 3 and the base 4 are corresponding and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com