Wiper blade with jet separator

A separator and wiper technology, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve problems such as delays and achieve efficient cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

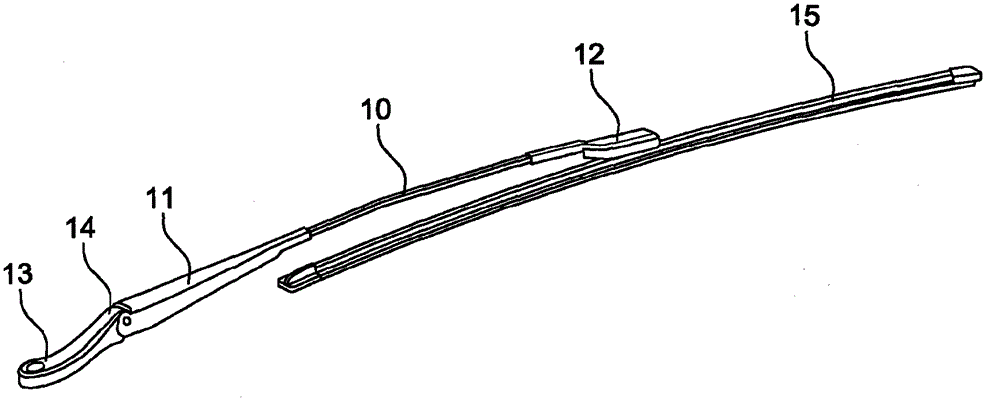

[0030] figure 1 A shaft 10 and a wiper wiper 15 according to the invention are shown. The rod body 10 includes a housing 11 at one of its two ends and a coupling cover 12 at the other end. The housing 11 is connected to the driver 13 via a hinge 14 . The driver 13 is connected with a motor (not shown), ensuring the rotary reciprocating motion of the wiper.

[0031] The coupling cover 12 connects the rod body 10 to the wiping wiper 15 , so that the wiper wiper 15 can rotate relative to the rod body 10 along the axis perpendicular to the rod body 10 at the coupling cover 12 .

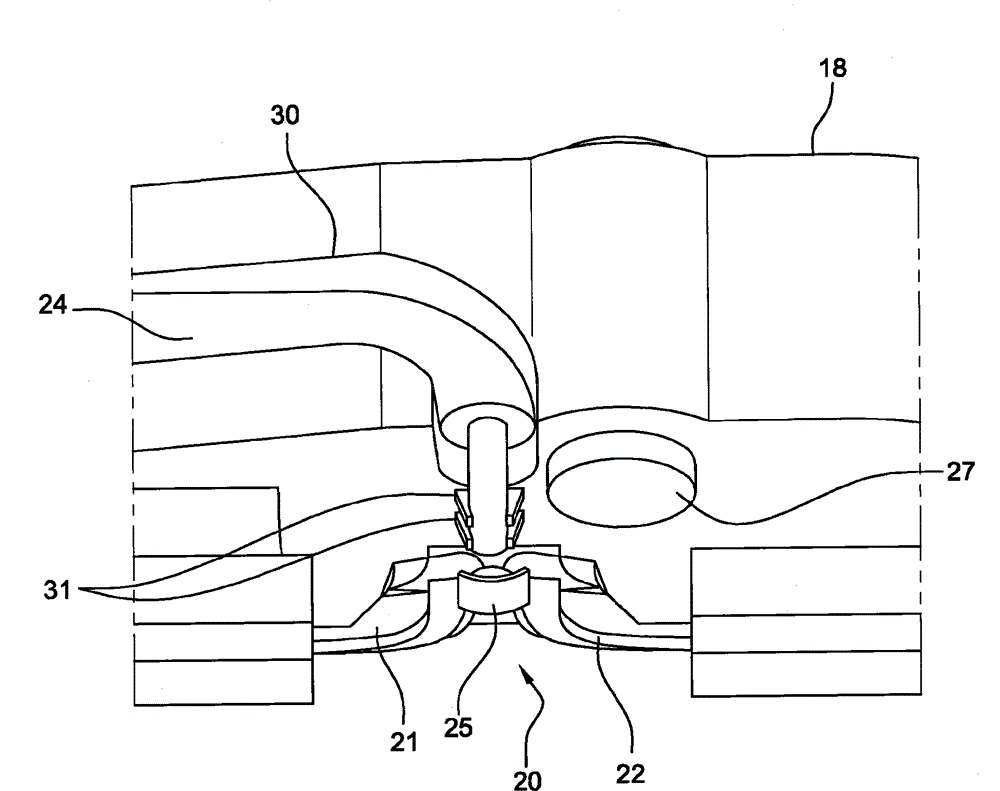

[0032] The windshield wiper 15 according to the invention comprises an injection opening from which the jet jet is divided into a plurality of jet streams by a separator. Each jet is directed towards a portion of the wiper blade 17 (or wiper sheet) by the separator.

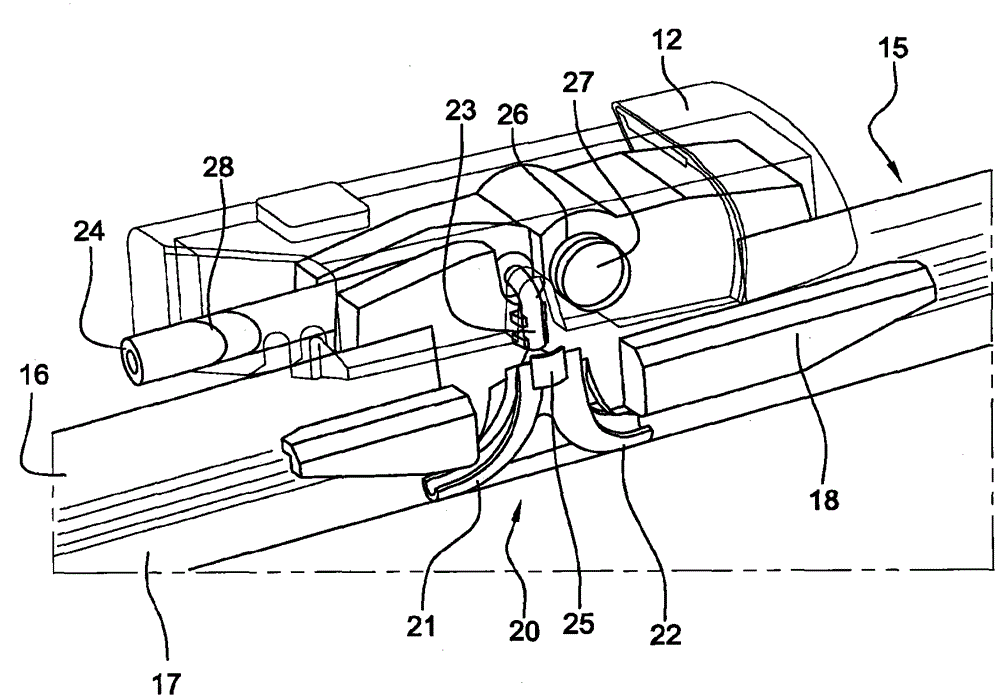

[0033] refer to figure 2 , 3 and 4, the wiping wiper 15 includes a deflector 16 , a wiping sheet 17 and an adapter 18 . The deflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com