Transferring cleaning trolley

A technology for cleaning trolleys and car bodies, applied in cleaning methods and appliances, cleaning methods using gas flow, chemical instruments and methods, etc., which can solve problems such as difficult equipment, reduced transfer efficiency, and long time-consuming transfer carts, and achieve convenient observation Meticulous, efficiency-enhancing, and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

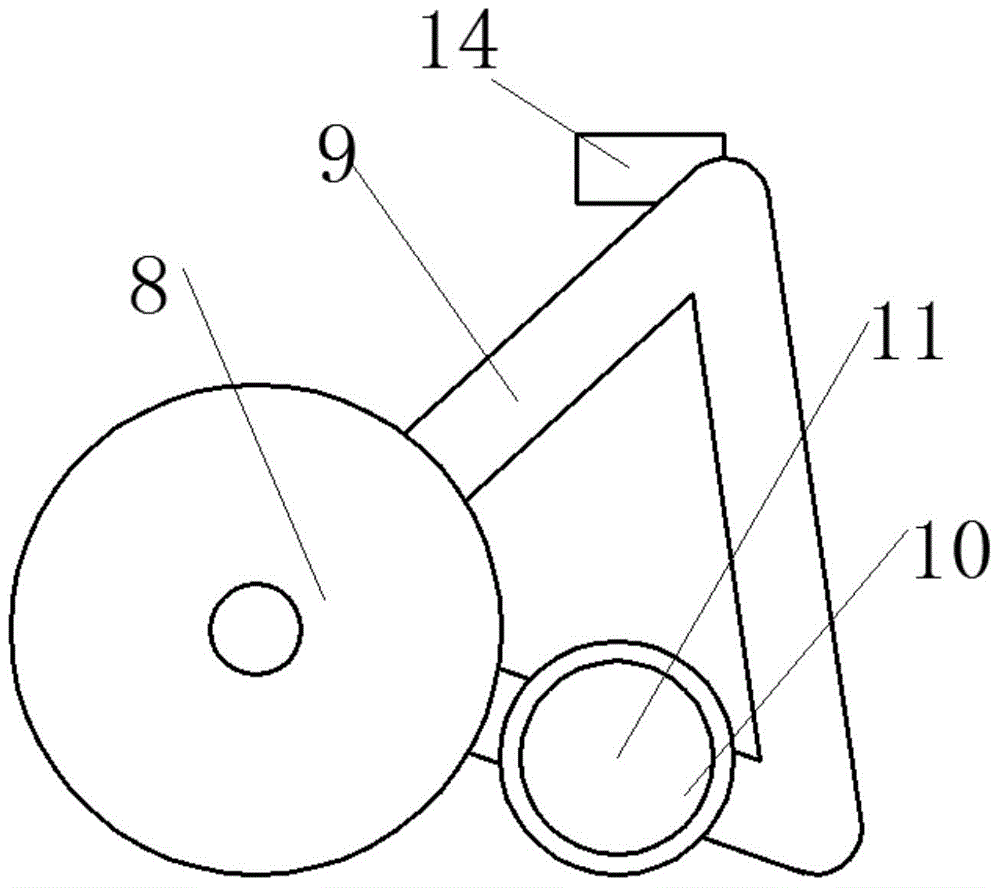

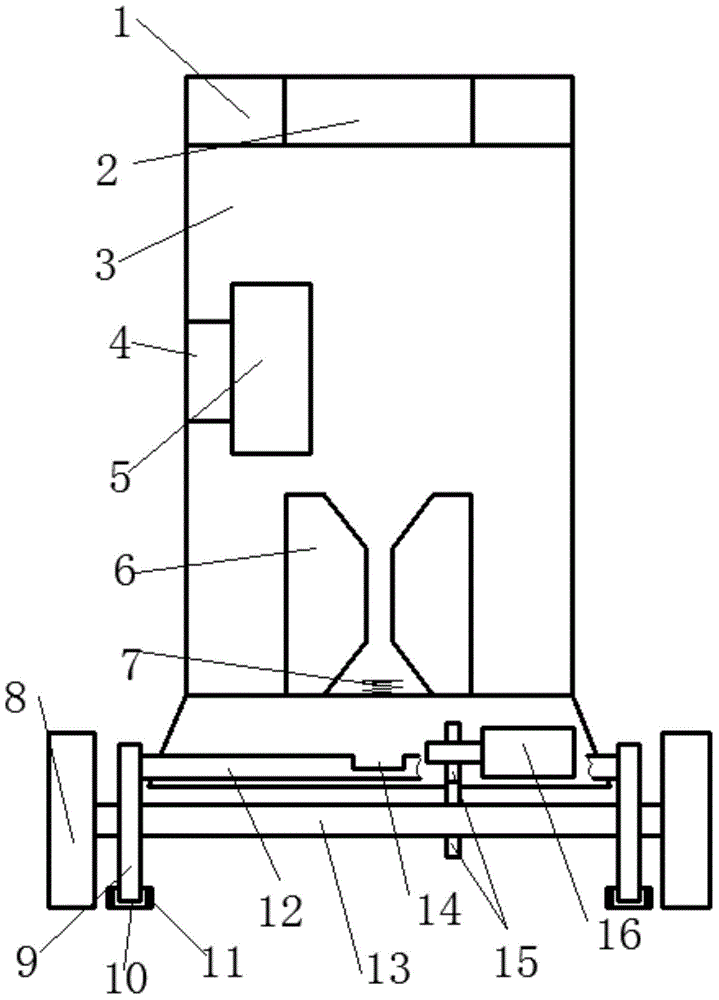

[0014] figure 1 and figure 2 Show a specific embodiment of a transfer cleaning trolley of the present invention: a transfer cleaning trolley, comprising a car body 3 and a base, wherein the top end of the car body 3 is provided with an end cover 1, and an observation plate 2 is provided in the middle of the end cover 1 to observe The plate 2 is made of a transparent convex material, the end cover 1 and the car body 3 are hinged, the two ends of the inner bottom of the car body 3 are provided with fixing clips, the fixing clips are composed of two clamping blocks 6, and the section of the clamping blocks 6 is isosceles Trapezoidal, the inside surface of car body 3 is provided with blower 5, is provided with support 4 between blower 5 and car body 3, is universal connection between support 4 and car body 3, and described base is positioned at car body 3, and base There is a variable speed motor 16 inside, and rollers 8 are arranged on both sides of the base. The central shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com