Multi-spray-head interference-free printing method and spray head structure of 3D printer

A 3D printer, non-interference technology, applied in printing and other directions, can solve the problems of increasing failure rate, increasing printer volume, interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

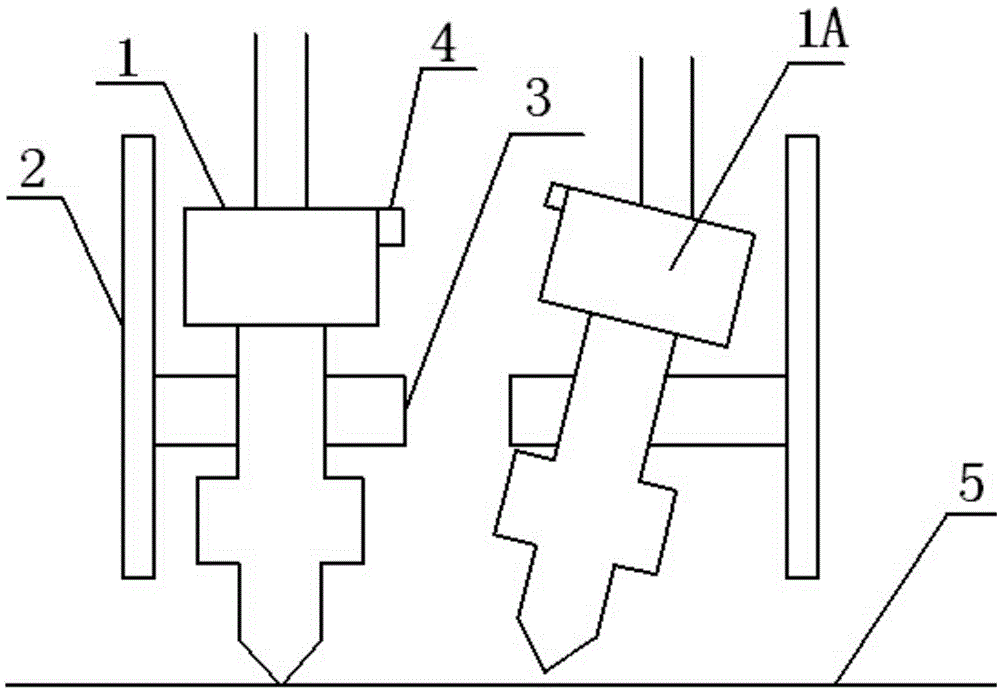

[0019] combine figure 1 , a 3D printer multi-nozzle non-interference printing method, a tilting device is provided for each nozzle, and the non-working nozzle is tilted during printing so that the top nozzle is separated from the working plane, and only the nozzle of the working nozzle is at the working height. After the nozzle is tilted, the nozzle is 0.4-0.8mm away from the working plane after the nozzle is tilted. In the figure, the spray head 1 is in the working state, and the spray head 1A is a spray head that is tilted away from the working plane 5 .

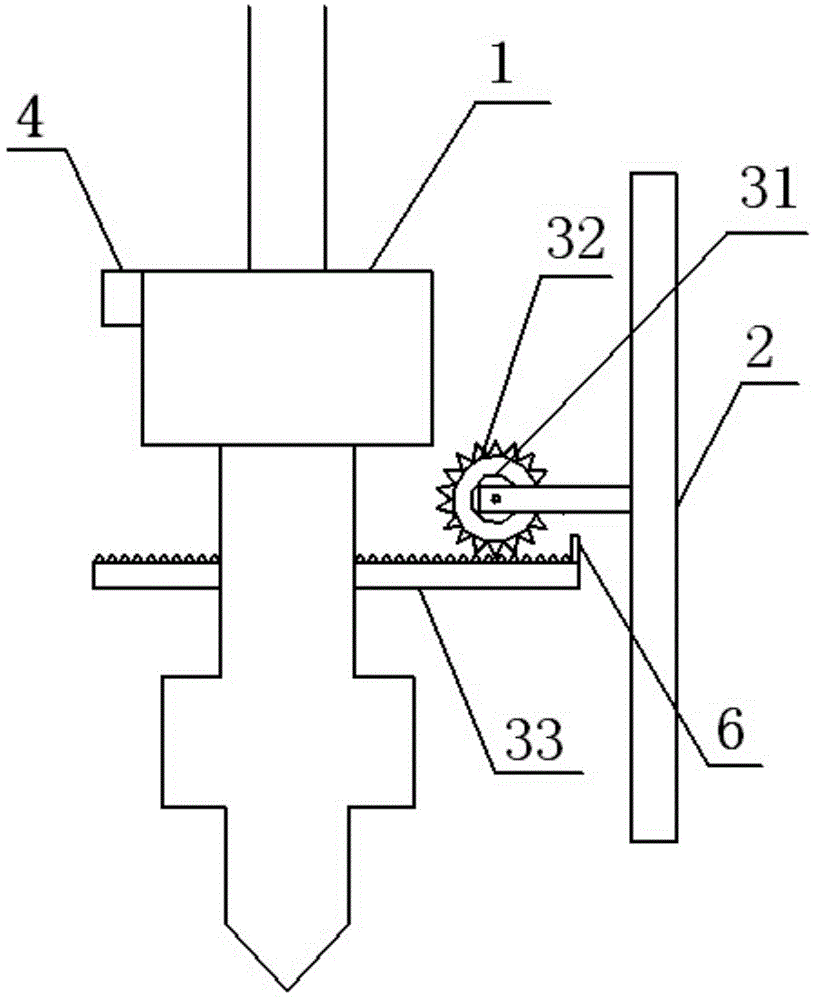

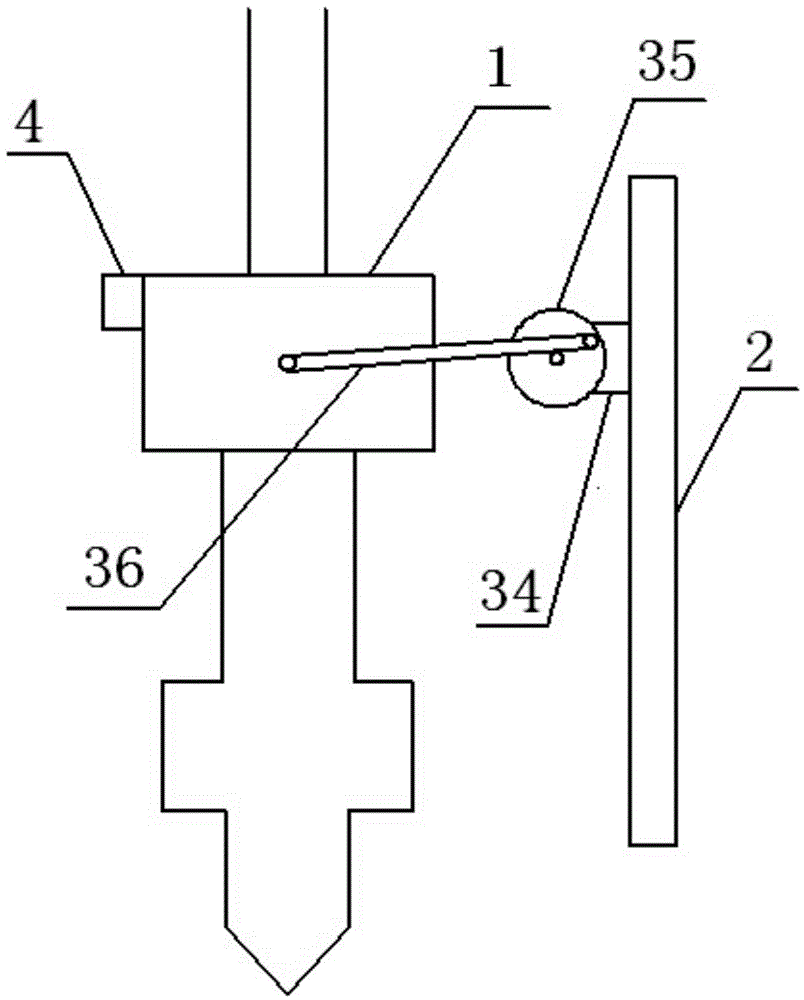

[0020] Such as figure 1 As shown, a 3D printer nozzle structure adopting the above-mentioned non-interference printing method includes a nozzle 1, a guard plate 2, and a tilting device 3 connected to the nozzle and the guard plate respectively. In this embodiment, the tilting device includes a driving assembly f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com