Self-detecting circuit and self-detecting method for open-loop optical fiber gyroscope

A technology of self-checking circuit and fiber optic gyroscope, which is applied in the direction of Sagnac effect gyroscope, gyroscope/steering sensing equipment, measuring device, etc., can solve the problem that the open-loop fiber optic gyroscope cannot perform self-checking, and achieve good self-checking Effects, solutions that cannot be self-tested, and effects that are easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the drawings.

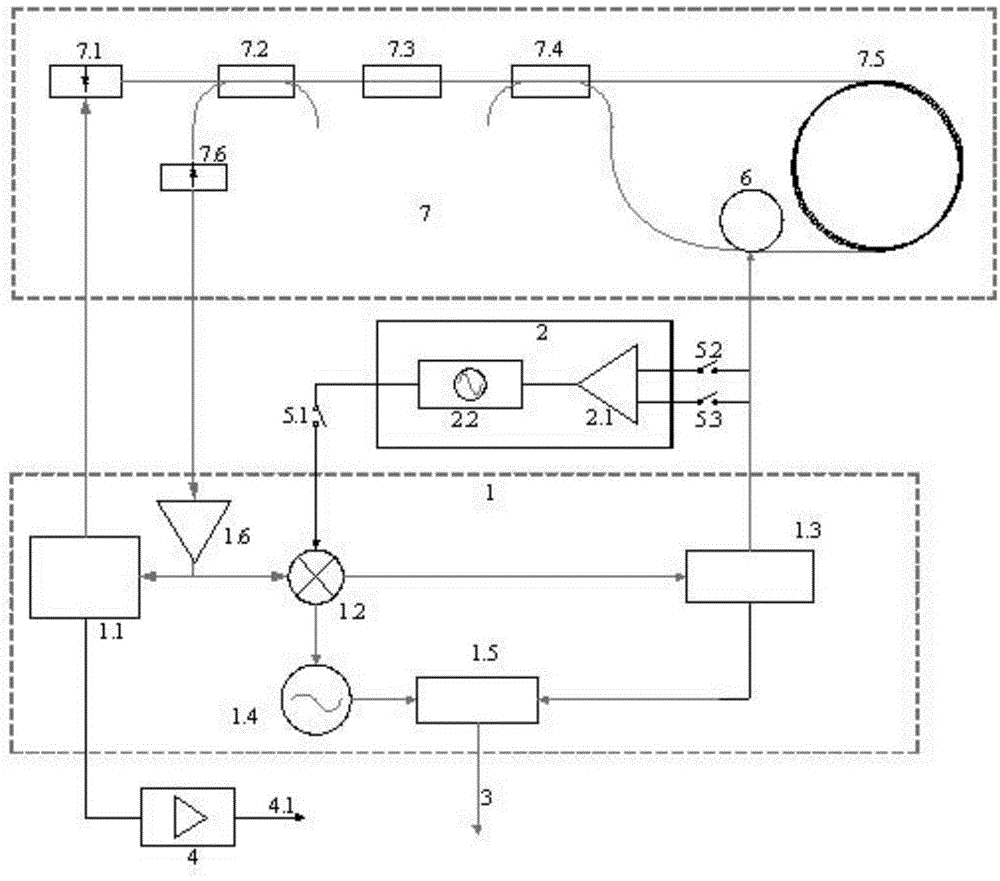

[0020] Reference figure 1 , The light source driving circuit 1.1 drives the light source 7.1 to emit light, through the light source coupling and docking, so that the light emitted by the light source enters the optical fiber, and the light is transmitted along the optical fiber. After passing through the coupler C2 7.2, the polarizer 7.3 and the coupler C1 7.4, it is divided into two beams. For light beams propagating in two directions, one of the fibers is wound on the PZT 6, and the signal modulation circuit 1.3 generates a sinusoidal signal with a modulation frequency that is doubled to make the PZT 6 oscillate, so that the light transmitted in the two directions is modulated by PZT 6 with a time difference of one time. τ, because the modulation time of the two beams is different, a non-reciprocal error will occur, that is, when the two beams meet again, a phase difference will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com