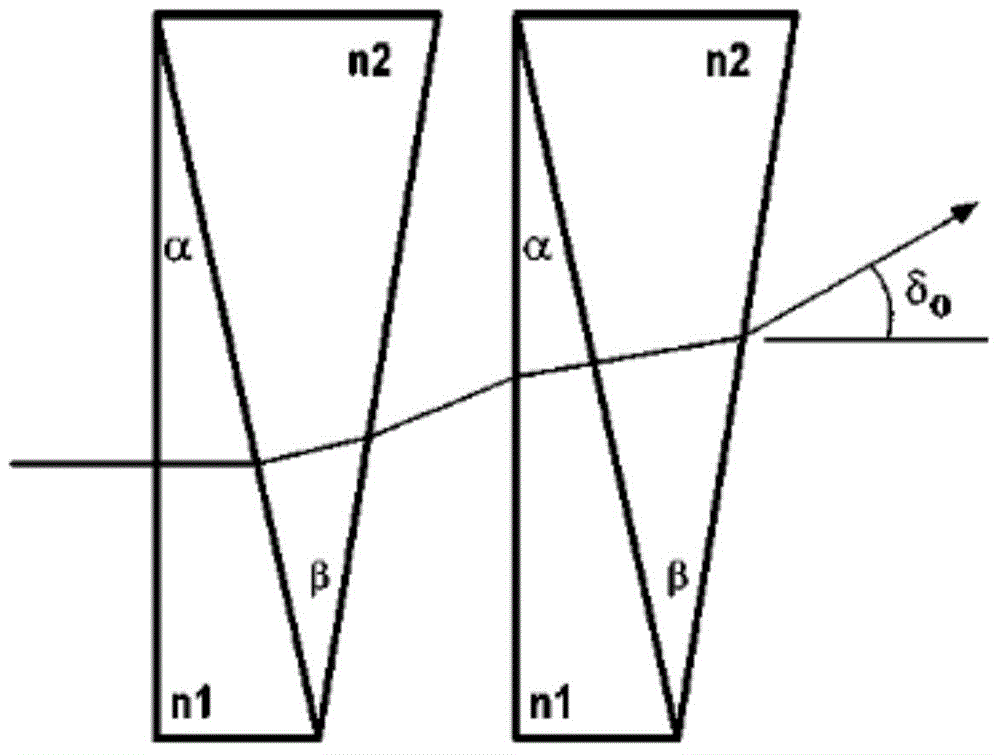

Composite achromatic prism phase detecting and assembling method

An assembly method and phase detection technology, which is applied in the field of photoelectric tracking, can solve the problems that it is difficult to achieve second-level detection accuracy, cannot meet the high-precision requirements of achromatic prisms, and cannot achieve accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

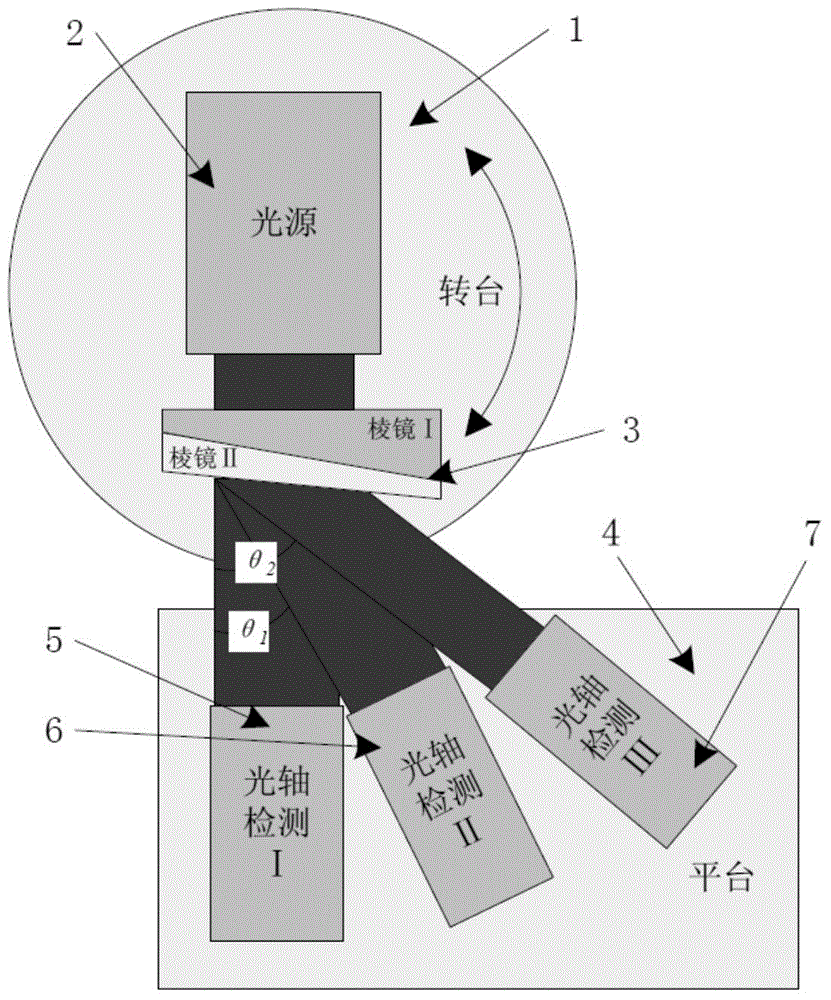

[0024] In order to make the purpose and technical solution of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

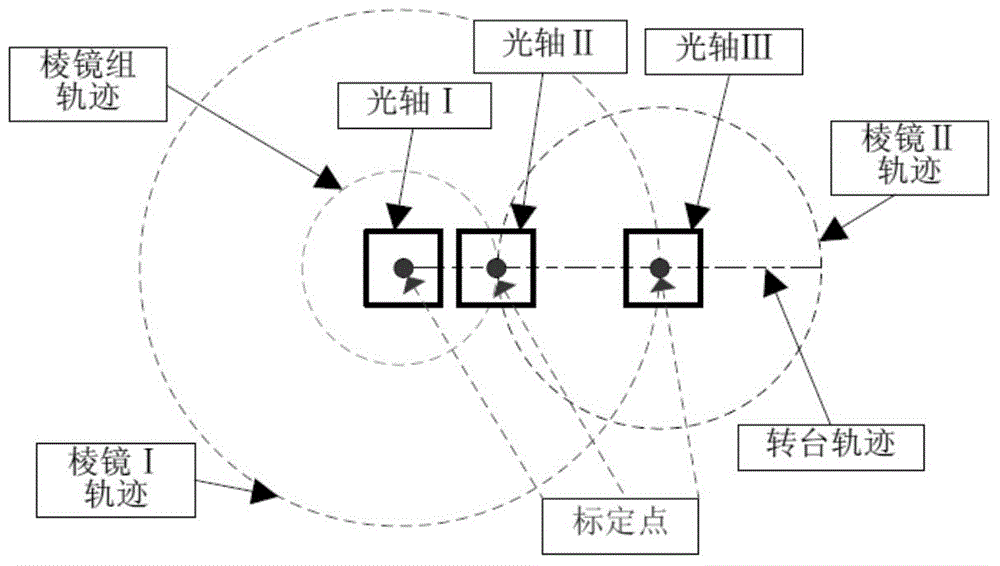

[0025] combine first figure 2 The achromatic prism phase detection method is introduced. This method requires the use of turntable (1), light source (2), achromatic prism group (3), platform (4), optical axis detection I (5), optical axis detection II (6) and optical axis detection III (7) , wherein the achromatic prism group (3) includes prism I and prism II.

[0026] Optical axis detection 5, 6 and 7 have longer focal length and high resolution, but the field of view is smaller, usually about 0.2-0.4°, focal length is about 2-3m, resolution is about 0.1-1.0″, the field of view of optical axis detection Far smaller than the light deflection angle of the prism (about 10-70°), the detection of the prism group cannot be completed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com