AMT motor brush carrier assembly

A motor brush and brush holder technology, applied in electric components, electrical components, electromechanical devices, etc., can solve the problems of cumbersome assembly procedures, loose printed circuit boards, increased development costs, etc., to reduce the probability of loosening and even damage, and enhance waterproofing Dustproof function, high space utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

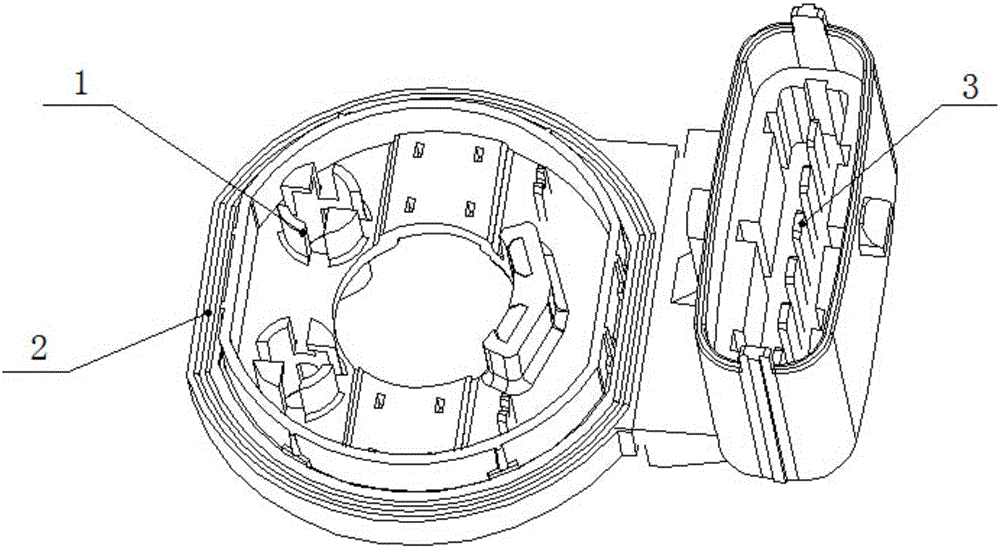

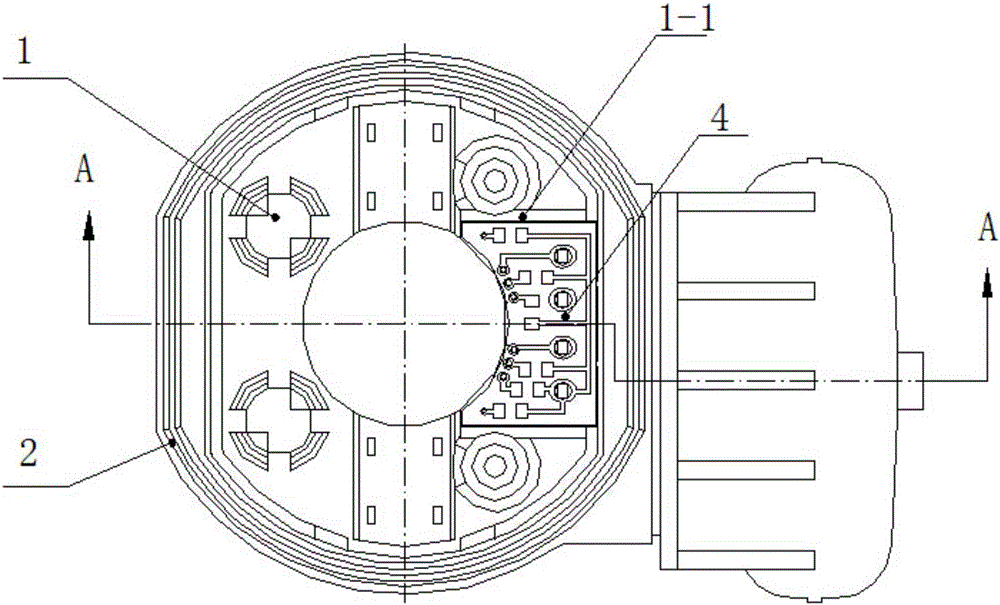

[0014] Such as Figure 1~4 As shown, an AMT motor brush holder assembly includes a brush holder 1 and a printed circuit board 4, the outer ring of the brush holder 1 is provided with rubber seals 2, and the brush holder 1 is provided with a plug-in structure. Terminals 3 are injection molded, and the printed circuit board 4 is electrically connected to the brush holder 1 through the terminals 3 .

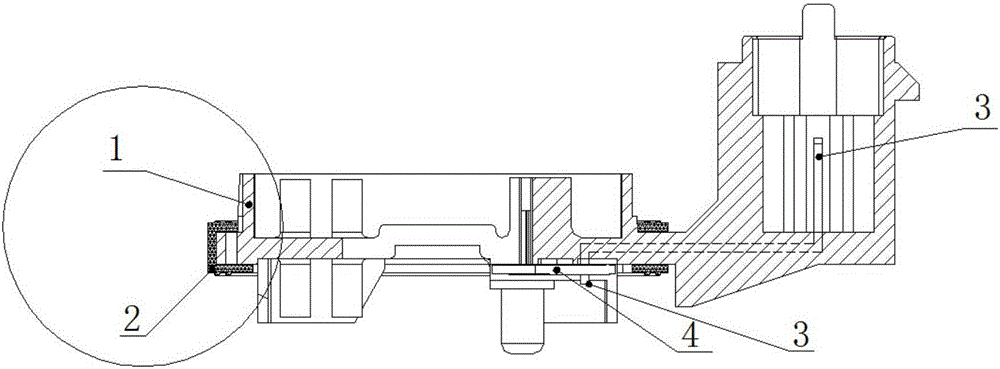

[0015] Such as figure 2 As shown, the brush holder 1 is provided with a positioning groove 1-1 matched with the printed circuit board 4, and the printed circuit board 4 is installed in the positioning groove 1-1 and closely fits with the positioning groove 1-1.

[0016] Such as image 3 , 4 As shown, the printed circuit board 4 is soldered to the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com