High Speed Hallless Three Phase Vacuum Cleaner Motor

A vacuum cleaner and Hall sensor technology, applied in the field of high-speed non-Hall three-phase vacuum cleaner motors, can solve the problems of low rotation speed, reduce reliability, increase motor volume, etc., reduce the number of commutations, and reduce commutation. Loss and productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

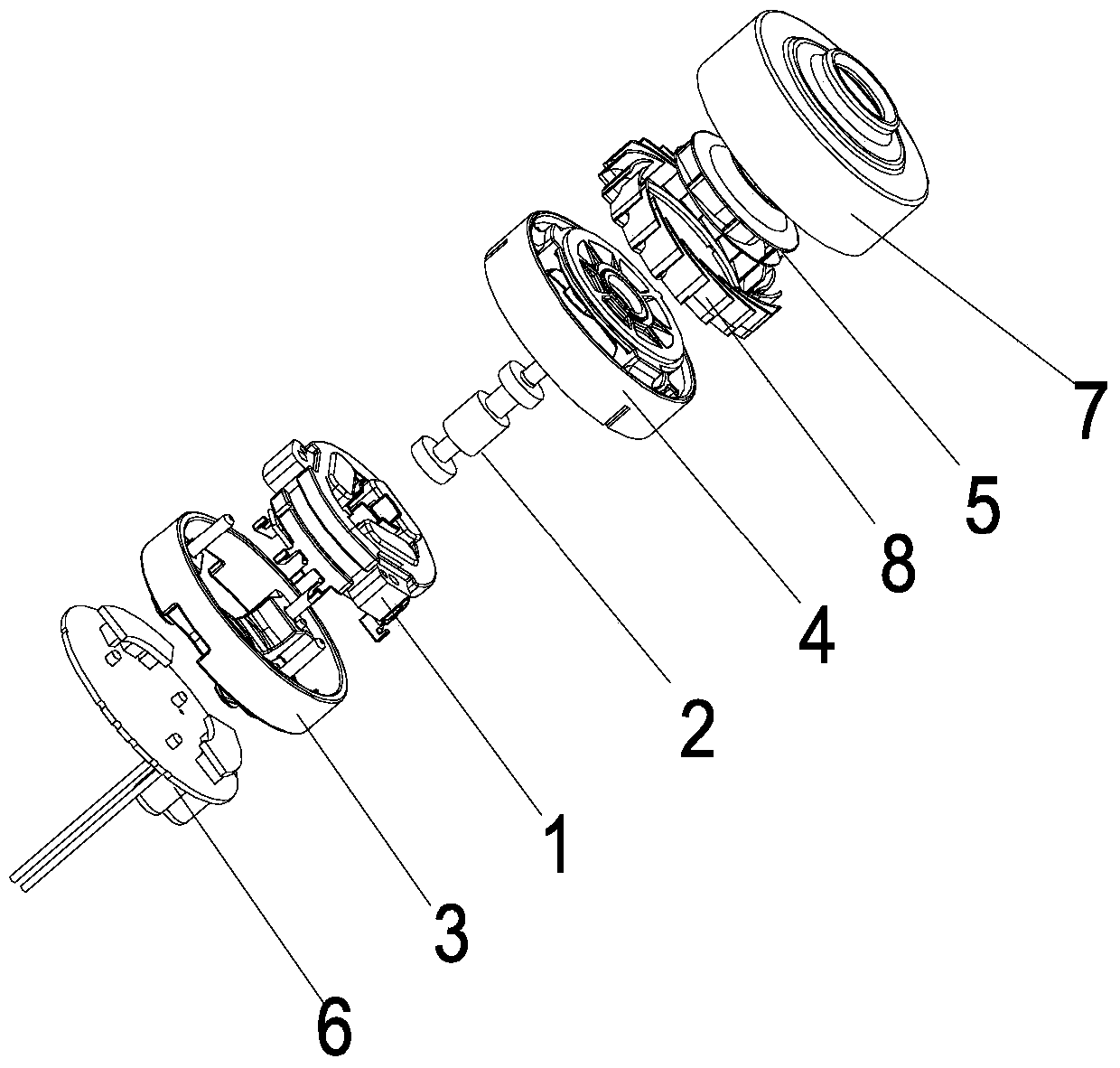

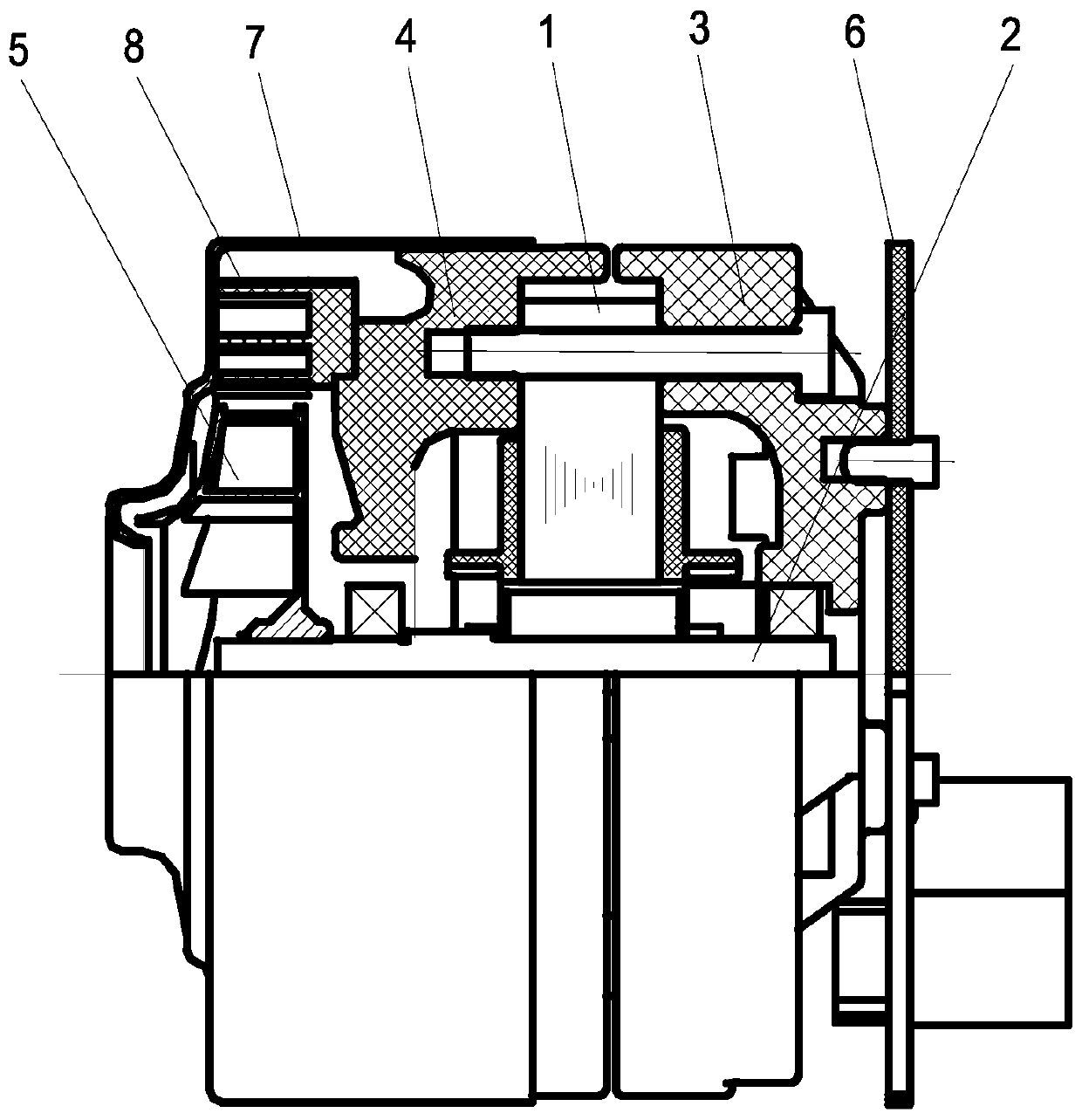

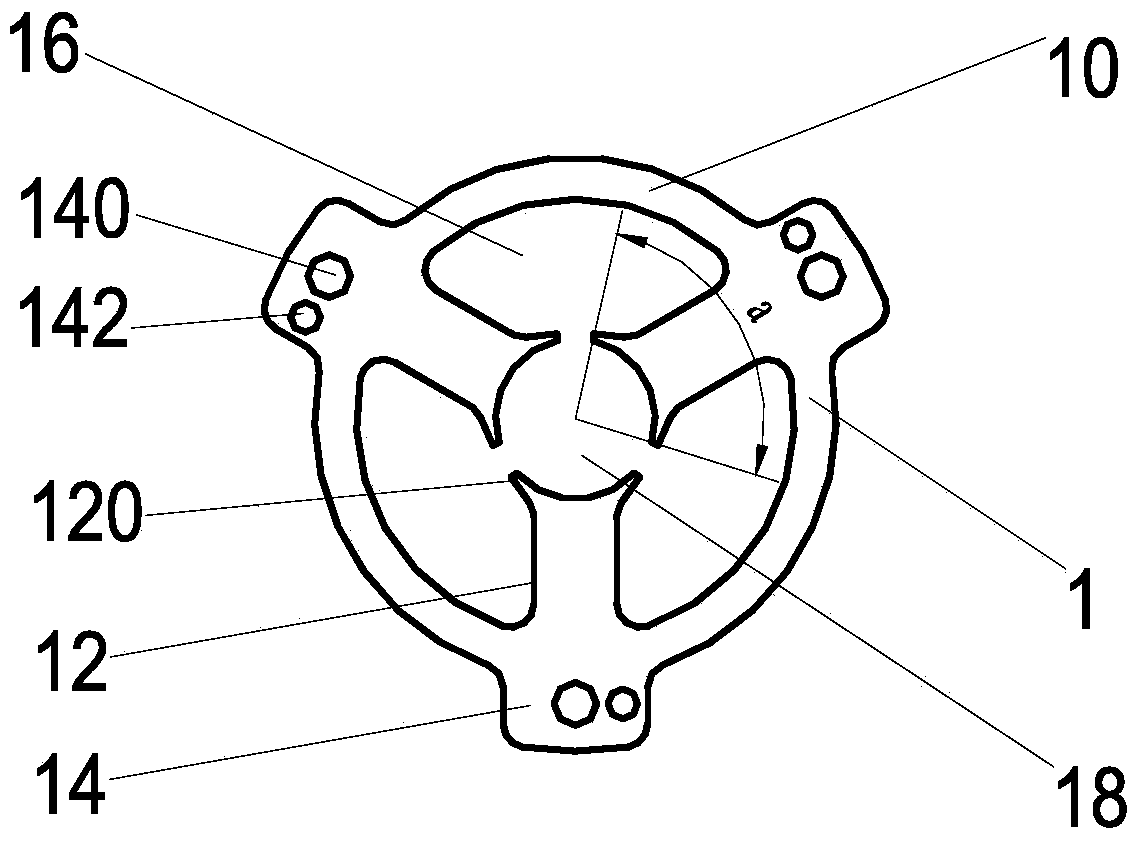

[0031] Example: such as Figure 1-5 As shown, the present invention provides a specific embodiment of a high-speed Hallless three-phase vacuum cleaner motor, preferably a brushless DC motor, which includes an iron core 1 with a central circle 18, a rotor 2 passing through the central circle 18, and a The first end cover 3 on one end of the fixed iron core 1, the second end cover 4 that cooperates with the first end cover 3 and fixes the other end of the iron core 1, and the moving motor located on one side of the second end cover 4 and driven by the rotor 2 The impeller 5, the impeller cover 7 that accommodates the moving impeller 5 and is fixed to the second end cover 4, the fixed impeller 8 located between the second end cover 4 and the moving impeller 5, and the circuit board 6 located outside the first end cover 3, The circuit board 6 has a Hall-less sensor circuit cooled by the motor outlet air, and the motor speed controlled by the Hall-less sensor circuit is greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com