Single-sided square indexable cutting inserts and cutting tools

A technology for cutting inserts and cutting tools, which is applied to cutting blades, tools for lathes, forming knives, etc., and can solve problems such as unacceptable and invalid joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

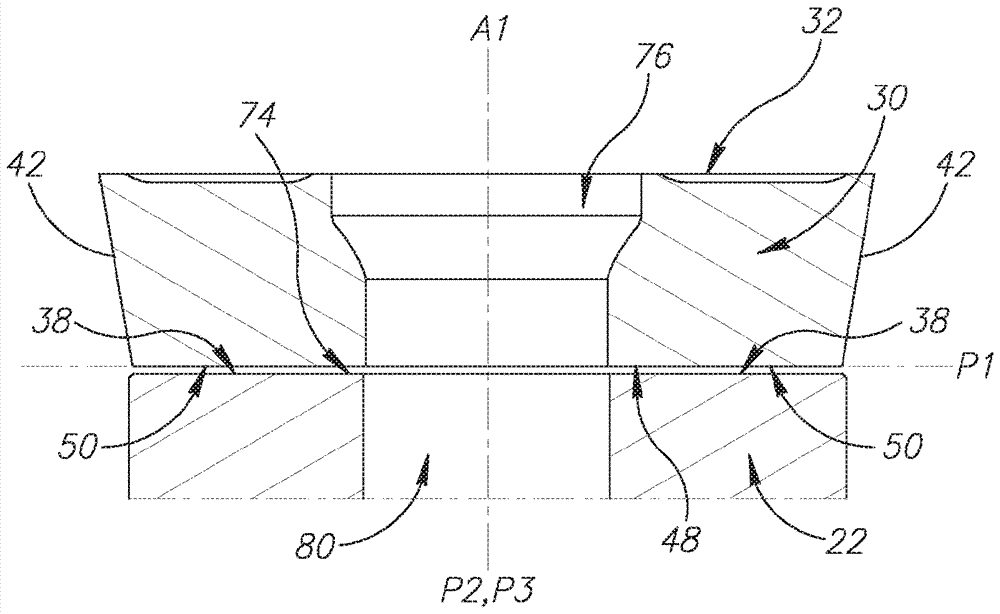

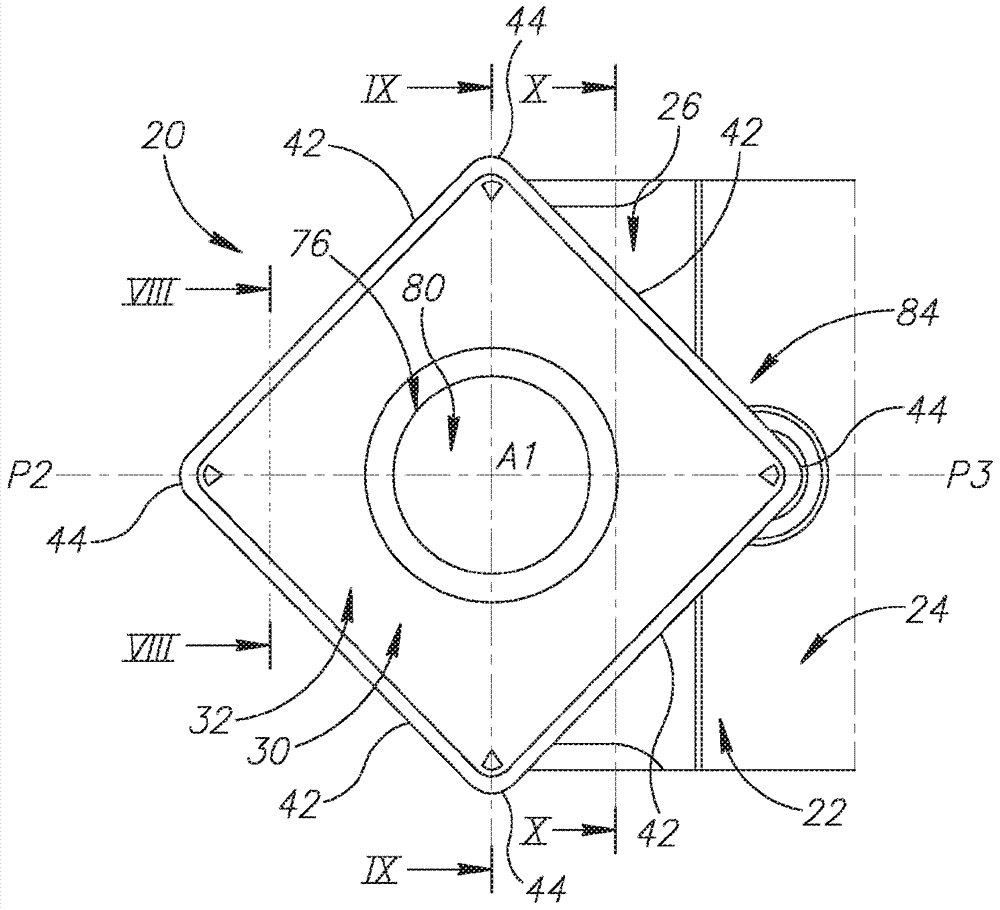

[0044] The present invention relates to a cutting tool 20 comprising a tool holder 22 having a main body 24 with an insert receiving pocket 26 formed at a front end 28 thereof and a single-sided indexable cutting insert 30 . A single-sided indexable cutting insert 30 is removably secured in the insert receiving pocket 26 .

[0045] In some embodiments of the present invention, such as figure 1 and 2 As shown, the cutting tool 20 may be in the form of a turning tool having a holder shank 82 extending away from the front end 28 of the body 24 .

[0046] Also, in some embodiments of the invention, the tool holder 22 may be made of machined steel and the cutting insert 30 is preferably made by forming and sintering cemented carbide (eg, tungsten carbide), And can be coated or uncoated.

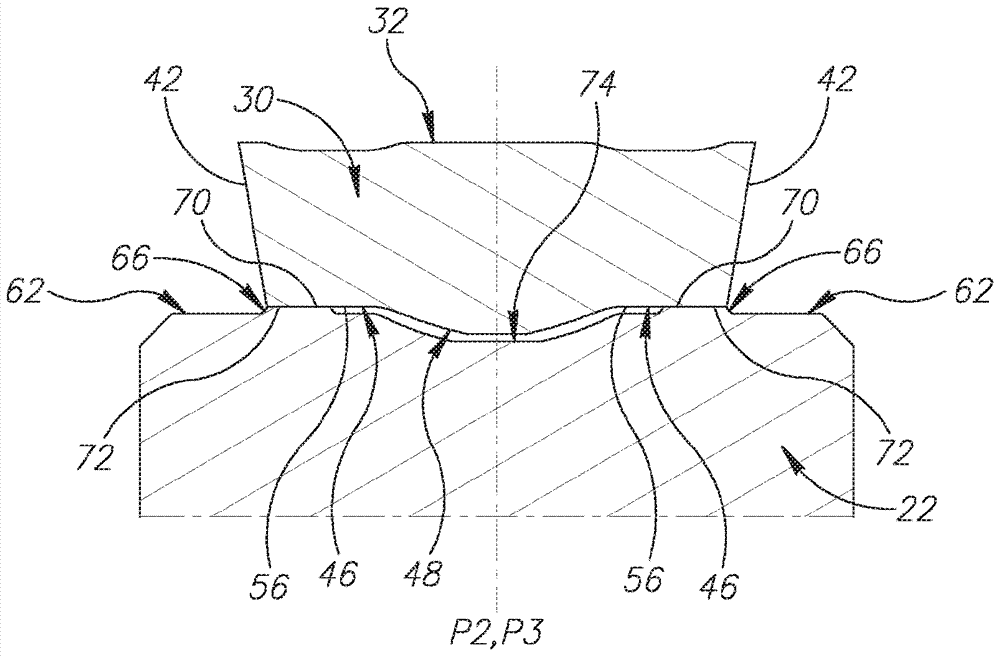

[0047] According to the present invention, if image 3 and Figure 4 As shown in , the cutting insert 30 has opposing square upper and lower surfaces 32, 34 and a peripheral side surface 36 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com