Fit-together pallet

An assembled and palletized technology, which is applied in packaging, transportation and packaging, rigid containers, etc., can solve problems such as inability to correspond, high cost of handling pallets, and increased unit price of production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

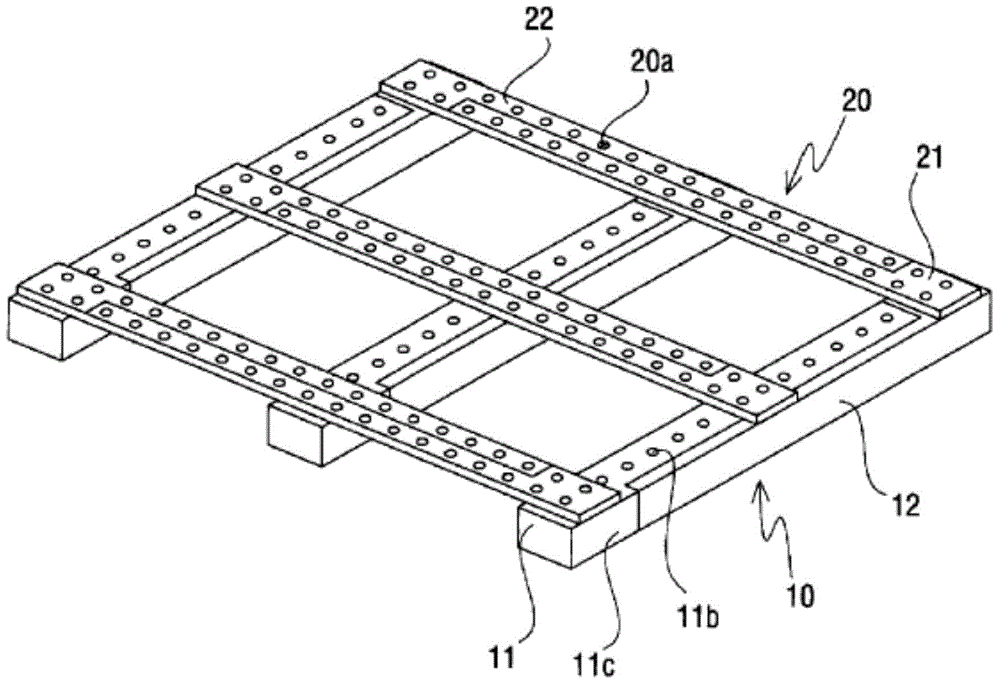

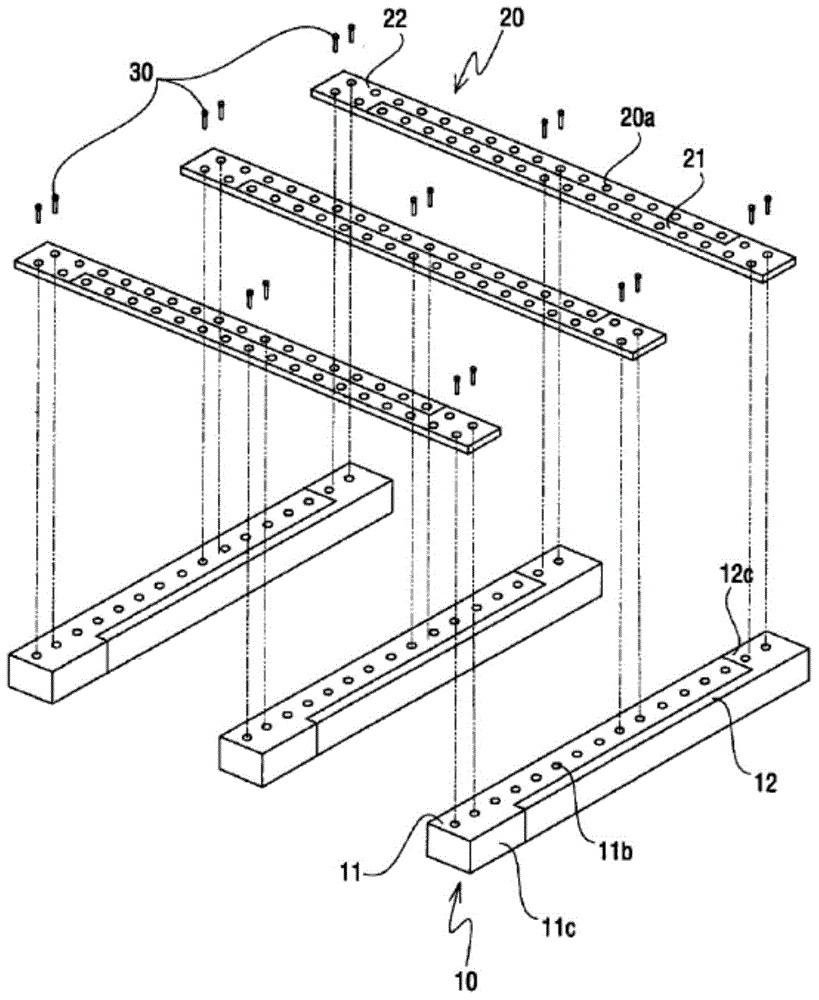

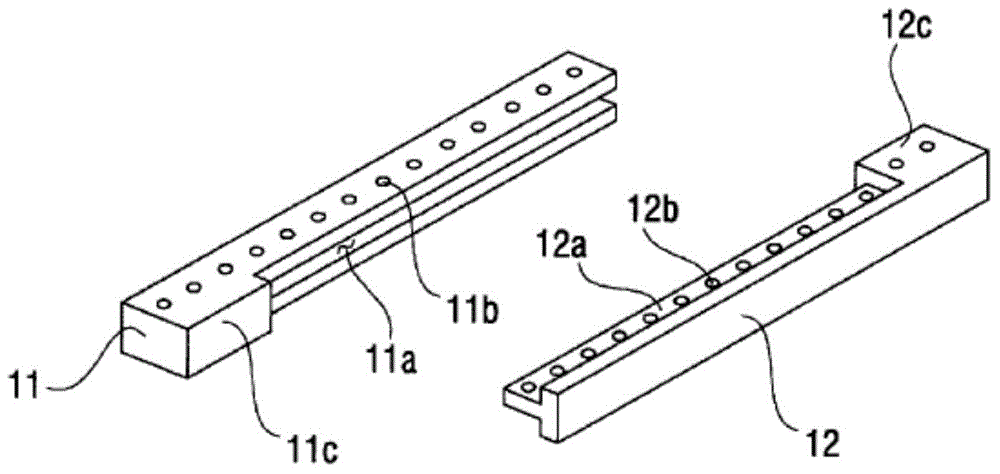

[0027] figure 1 is a perspective view of an assembled pallet according to an embodiment of the present invention; figure 2 It is an exploded perspective view of an assembled pallet according to an embodiment of the present invention; image 3 It is an exploded perspective view showing the stringer 10 of the assembled pallet according to the embodiment of the present invention; Figure 4 It is an exploded perspective view showing the beam 20 of the assembled pallet according to the embodiment of the present invention; Figure 5 It is a cross-sectional structure diagram of an assembled pallet related to an embodiment of the present invention; Image 6 It is a plan view showing the situation where the first protruding portion 11c and the second protruding portion 12c do not exist in the assembled tray according to the embodiment of the present invention; Figure 7 It is a perspective view which shows the state which changed the size of the prefabricated pallet concerning the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com