Liquid crystal composition and liquid crystal display element manufactured using same

A technology of liquid crystal display elements and liquid crystal compositions, which is applied to liquid crystal materials, chemical instruments and methods, instruments, etc., can solve problems such as insufficient effects, and achieve the effects of less screen burn-in and excellent high-speed response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0659] Hereinafter, the present invention will be described in more detail by citing examples, but the present invention is not limited to these examples. In addition, "%" in the composition of a following Example and a comparative example means "mass %".

[0660] The characteristics measured in the examples are as follows.

[0661] T NI : Nematic-isotropic liquid phase transition temperature (°C)

[0662] Δn: Refractive index anisotropy at 20°C

[0663] Δε: Dielectric constant anisotropy at 20°C

[0664] η: Viscosity at 20°C (mPa·s)

[0665] gamma 1 : Rotational viscosity at 20°C (mPa·s)

[0666] VHR: Voltage retention rate (%) at 70°C under the conditions of frequency 60Hz and applied voltage 5V

[0667] VHR after heat resistance test: The TEG (test element group) for measuring VHR injected with the liquid crystal composition was kept in a constant temperature chamber at 120° C. for 30 minutes, and then measured under the same conditions as the above-mentioned VHR mea...

Embodiment 4~7

[0717] Liquid crystal compositions (LC-5 to 8) having the following compositions were prepared, and their physical property values were measured. In addition, evaluations of burn-in, drop marks, process suitability, and solubility at low temperatures were performed using a liquid crystal display element. The results are shown below.

[0718] [Table 2]

[0719]

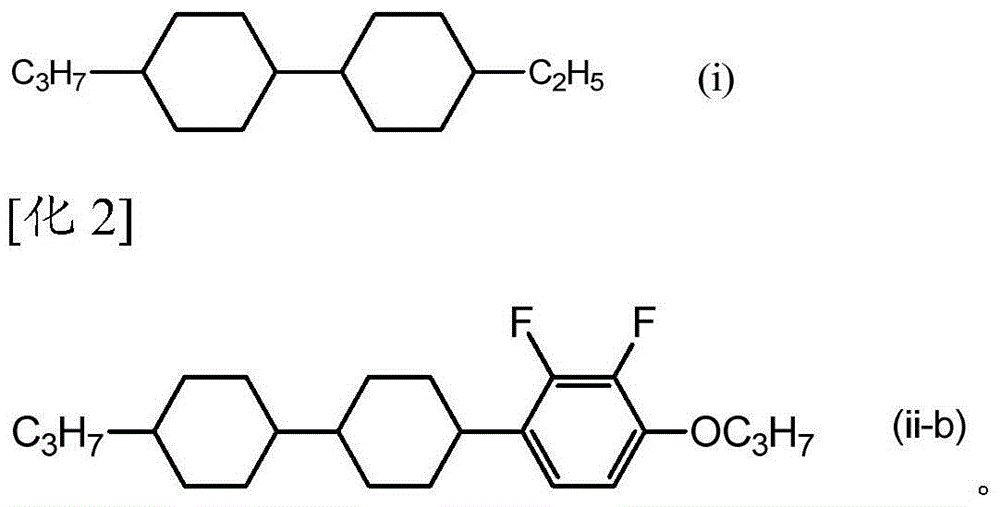

[0720] In the liquid crystal compositions LC-5 to 8 of Examples 4 to 7, the addition amount of the compound of formula (i) in the liquid crystal composition LC-6 of Example 5 was 4% by mass, so slightly inferior but still good results were obtained .

Embodiment 11~14

[0727] Liquid crystal compositions (LC-13 to 16) having the compositions shown below were prepared, and their physical property values were measured. In addition, evaluations of burn-in, drop marks, process suitability, and solubility at low temperatures were performed using a liquid crystal display element. The results are shown below.

[0728] [Table 4]

[0729]

[0730] The liquid crystal compositions LC-13-16 of Examples 11-14 obtained favorable results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com