Rubber combined stirrer

A combination and agitator technology, which is applied in the direction of mixer accessories, mixers, chemical instruments and methods, etc., can solve the problems of easily damaged mixing materials and insufficient mixing, and achieve good and sufficient mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

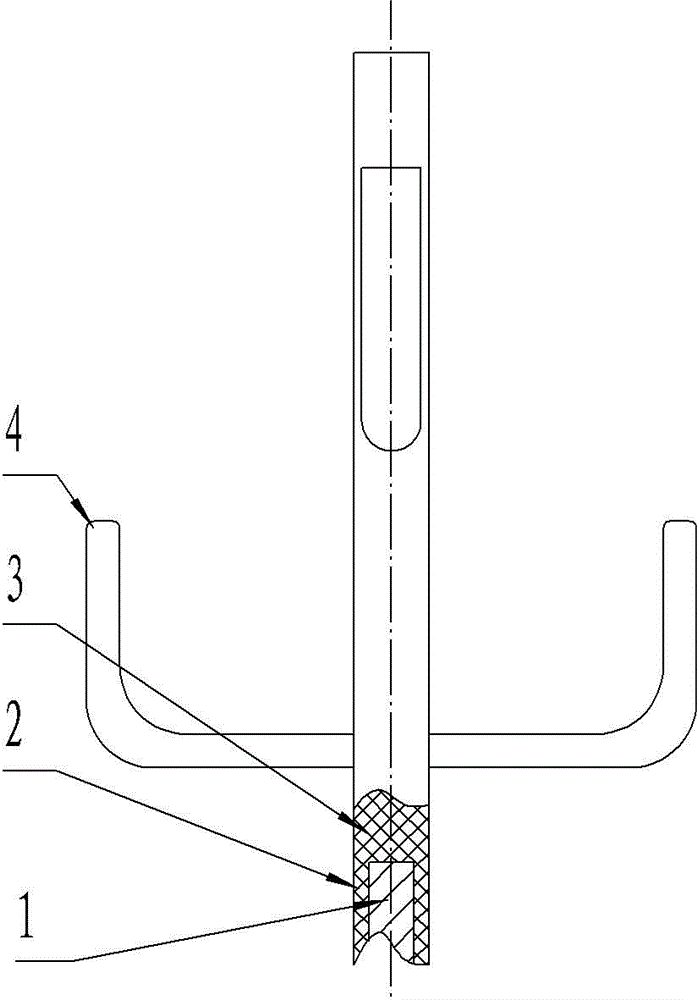

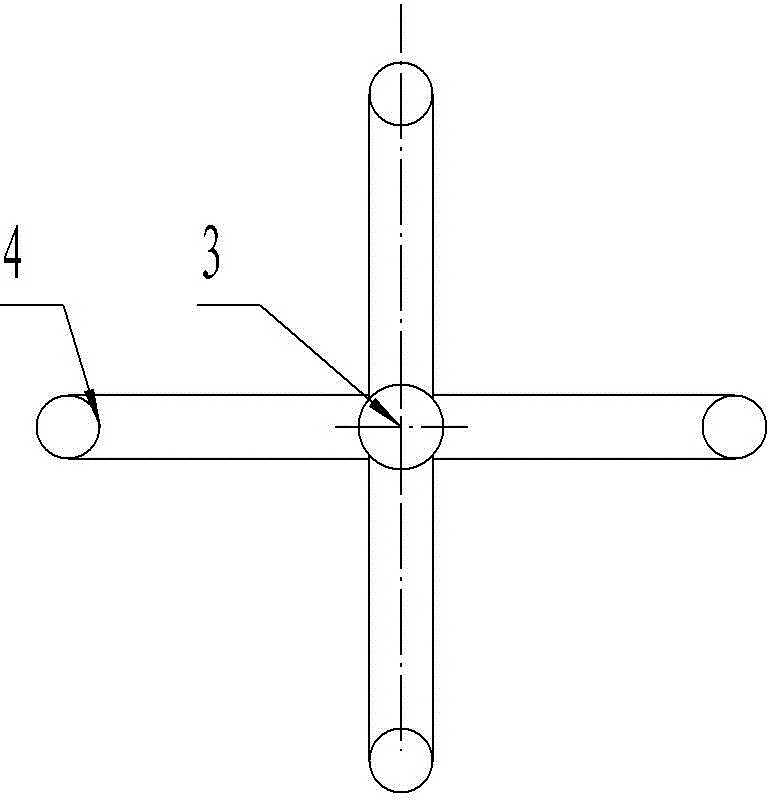

[0012] Such as figure 1 , figure 2 The rubber combined stirrer shown includes a rotating shaft, and two stirring rod groups are evenly distributed along the axial direction of the rotating shaft, and each group of stirring rods includes two stirring rods 4 evenly distributed around the rotating shaft. The bottom of the rotating shaft is a rotating part 1 of metal material, the outer layer of the rotating part 1 is provided with a rubber layer 2, and the upper part of the rotating part 2 is provided with a stirring part 3 of flexible material, so that the rotating shaft can flexibly bend and rotate like the stirring rod 4, The rotating shaft participates in the stirring together, so that the stirring effect is better and the stirring is more sufficient. The stirring rod 4 is a stirring rod 4 of flexible material, and the outer end of the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com