Electric-driven automatic refractory brick press and refractory brick forming method

A technology of refractory bricks and electric drive, which is applied in the direction of ceramic molding machines, auxiliary molding equipment, supply devices, etc., which can solve the problems of manual brick production safety hazards, no pre-release, and low cloth efficiency, and achieve high labor intensity and universal The effect of high stability and low cloth efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

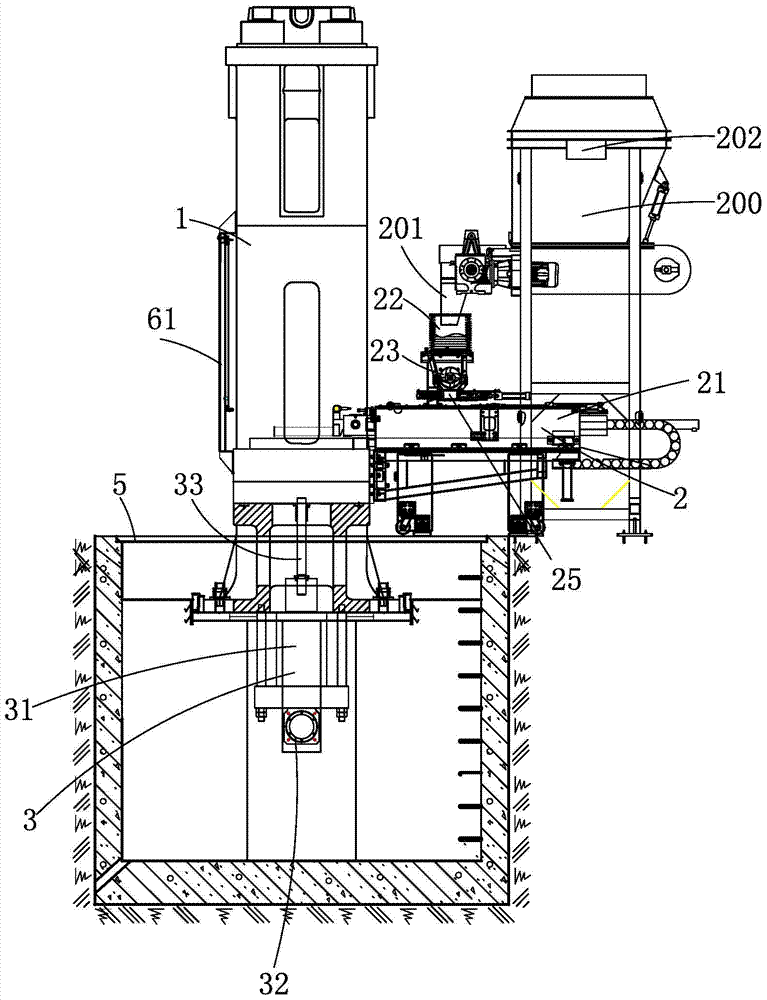

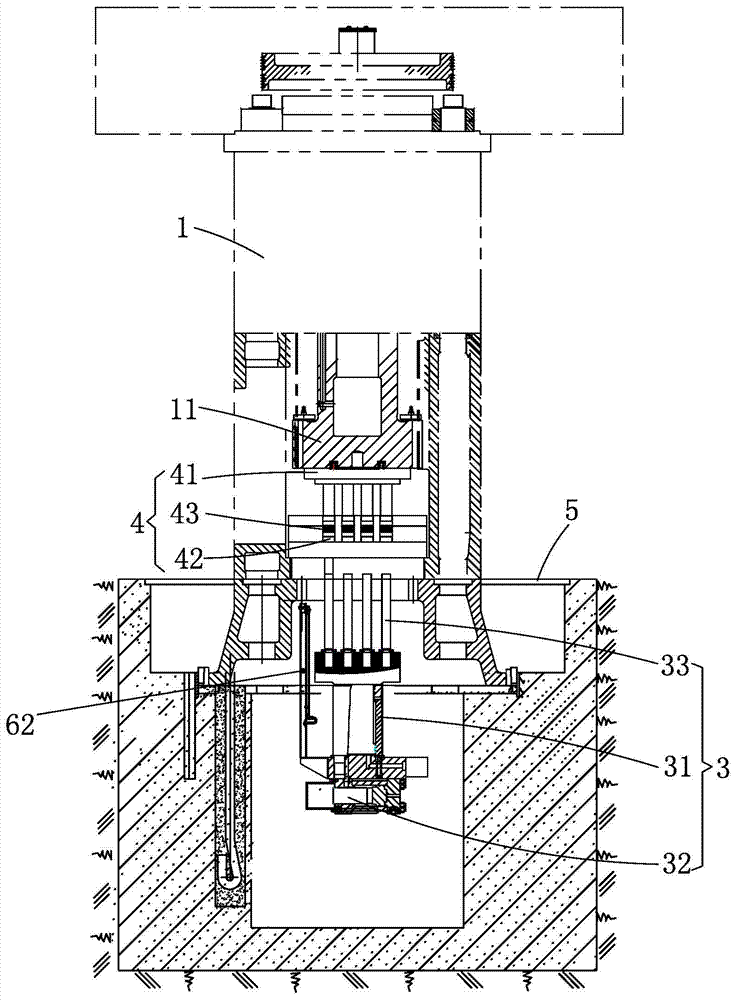

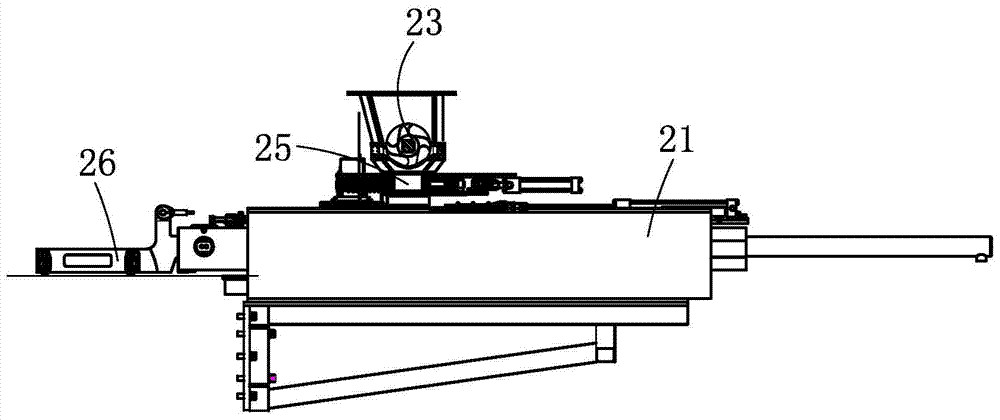

[0032] see Figure 1 to Figure 3 As shown, the electric-driven automatic refractory brick press of the present invention includes a brick pressing device 1, an automatic cloth clamping brick device 2, a ejector demoulding device 3, a mold 4, a workbench 5 and an electrical control system; and the brick pressing The device 1 is an electric drive press and is connected to the upper mold 41 through the pressure head 11. The automatic cloth clamping device 2 is installed on the workbench 5 and can be moved horizontally. The electric control system controls the automatic cloth clamping device 2. The raw material is loaded into the cavity 43 of the lower mold 42 at the set position, and after the pressing cycle is completed, the automatic cloth brick clamping device 2 is controlled to clamp the brick and push out the station along the workbench 5 .

[0033] The electric drive press is an electric screw press or a friction press.

[0034] The automatic cloth brick clamping device 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com