Improved electric car structure

A technology for electric vehicles and frames, which is applied in the field of improving the structure of electric vehicles. It can solve the problems of the weakening of the shock absorber itself, the reduction of the life of the range extender, and the damage of the range extender. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

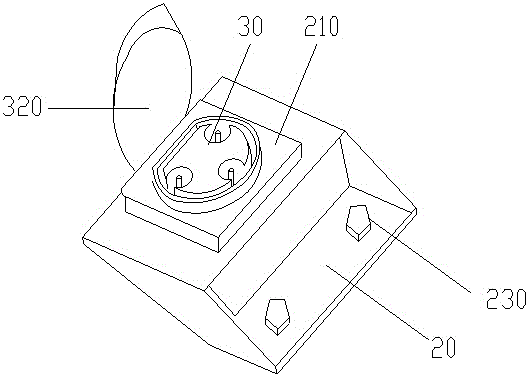

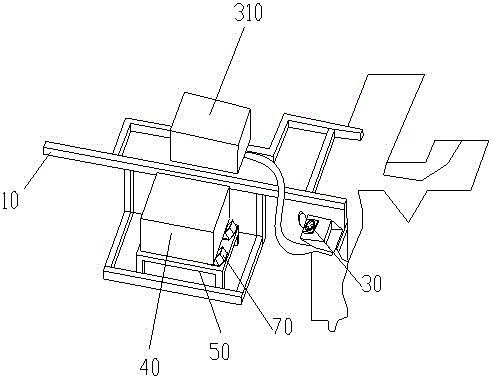

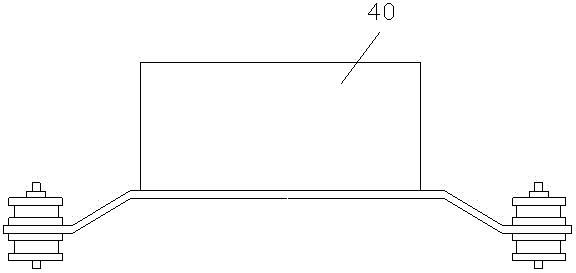

[0025] Such as Figure 1~2 As shown, an improved structure of an electric vehicle, a hybrid electric vehicle charger, includes a vehicle frame 10 at the front of the vehicle body, and a lateral support plate 20 is fixed to the side of the vehicle frame 10 at the front of the vehicle body, and the support plate A charging socket 30 is embedded in the middle of the vehicle body, and an energy storage device 310 is arranged on the frame 10 at the front side of the vehicle body, and the energy storage device 310 is connected to the charging socket 30 via a line.

[0026] The support plate 20 is stepped, and the outer step surface of the support plate is connected with the frame at the front side of the car body through bolts 230. The support plate 210 is threaded on the support plate, and the charging socket 30 is embedded in the support....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com