Wharf water supply pipe network online supervision method

A technology for water supply pipeline network and wharf, which is applied to pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc. It can solve the problems of wasting man-hours, difficult to locate the location of leakage, difficult to arrange pipeline maintenance work, etc. The effect of operating costs, reducing impacts, and avoiding water waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

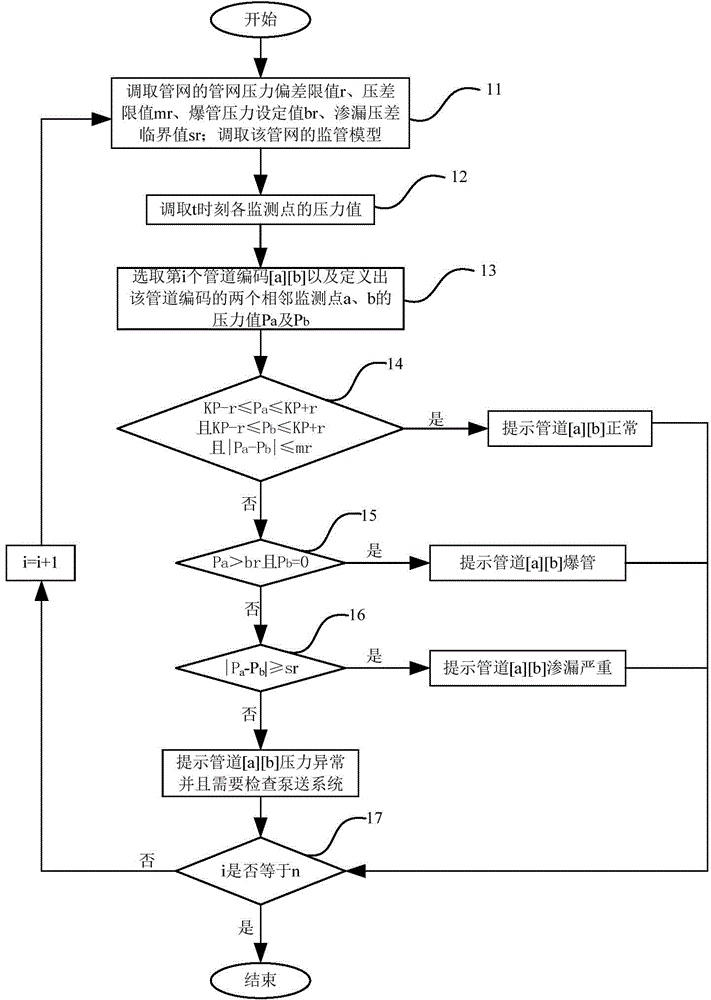

[0022] The specific embodiment of the present invention provides the method that carries out on-line supervision to wharf water supply pipe network (hereinafter referred to as pipe network), first sets the following parameters of this pipe network according to the actual design situation of pipe network: pipe network pressure deviation limit r , pressure difference limit value mr, burst pressure setting value br, leakage pressure difference critical value sr are used for subsequent judgment, and all parameters are positive values.

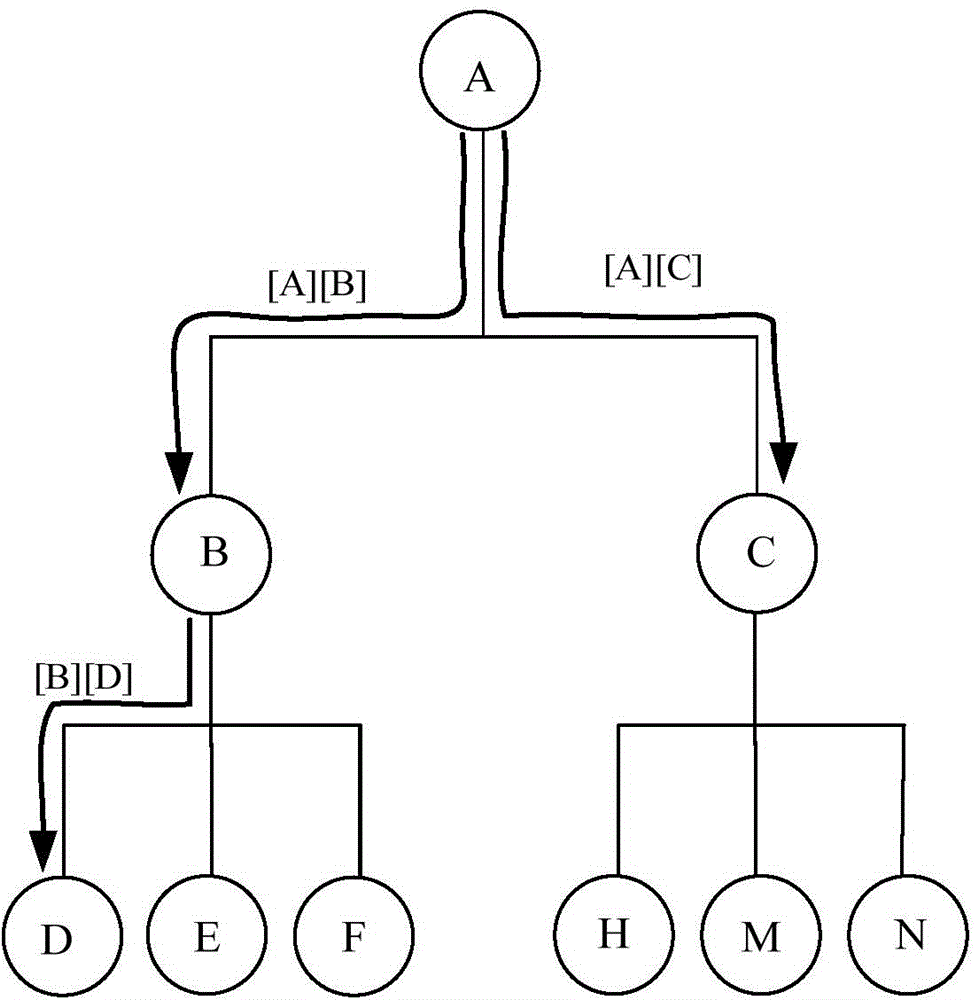

[0023] Secondly, establish a computer supervision model for the pipe network. The water supply pipe network of the wharf is a tree structure. Refer to figure 1 (Part of the schematic diagram of the supervision model), the circles in the figure represent the monitoring points in the pipe network, and the lines betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com