Fan subassembly for gas water heater

A technology for gas water heaters and fans, which is applied to fluid heaters, lighting and heating equipment, etc. It can solve the problems of easy corrosion and damage of welding or riveting joints, high cost of tooling and molds, and complex product structures, so as to improve production efficiency and product quality. The effect of simple structure and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

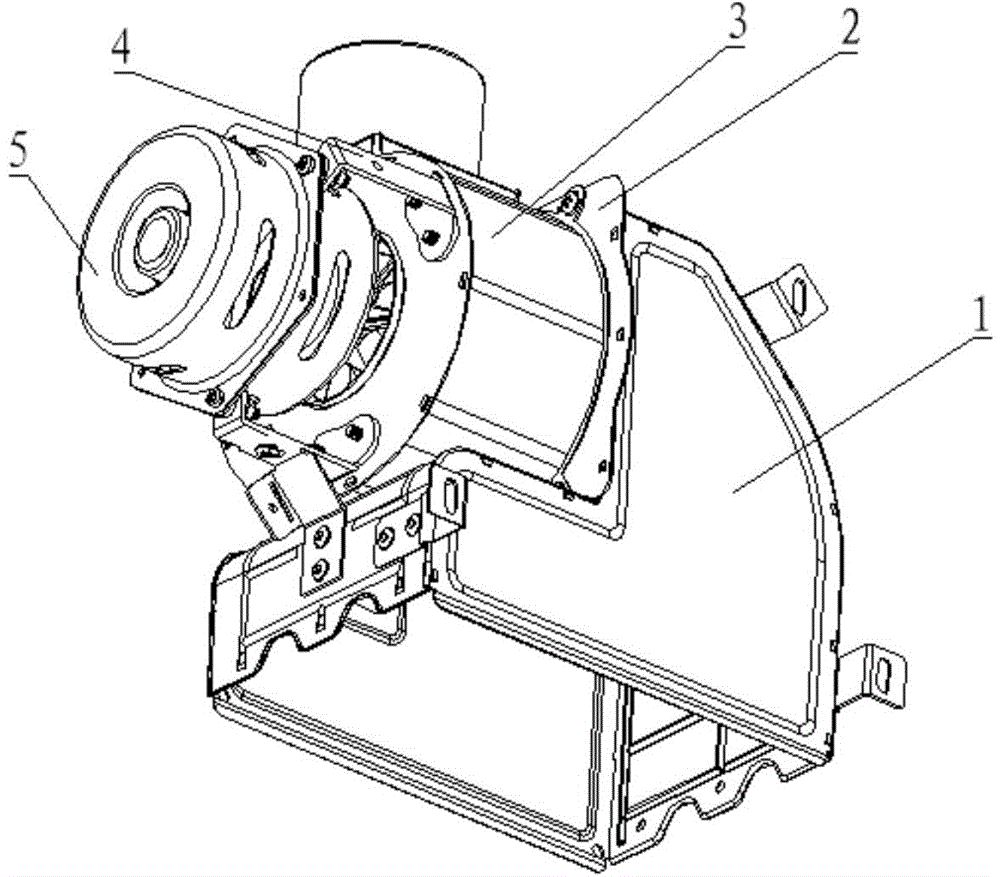

[0020] Such as figure 1 As shown, a fan unit for a gas water heater of the present invention includes a smoke inlet duct 1, a volute mounting plate 2, a volute assembly 3, a motor bracket 4, a motor 5, and a centrifugal wind wheel, and the volute mounting plate 2 is installed on At the smoke outlet 14 of the smoke inlet duct 1, the volute assembly 3 is installed on the volute mounting plate 2, the motor bracket 4 is fixed on the volute assembly 3, the motor 5 is installed on the motor bracket 4, and the centrifugal wind wheel is located on the volute Inside the shell assembly 3, it is fixed on the shaft of the motor 5.

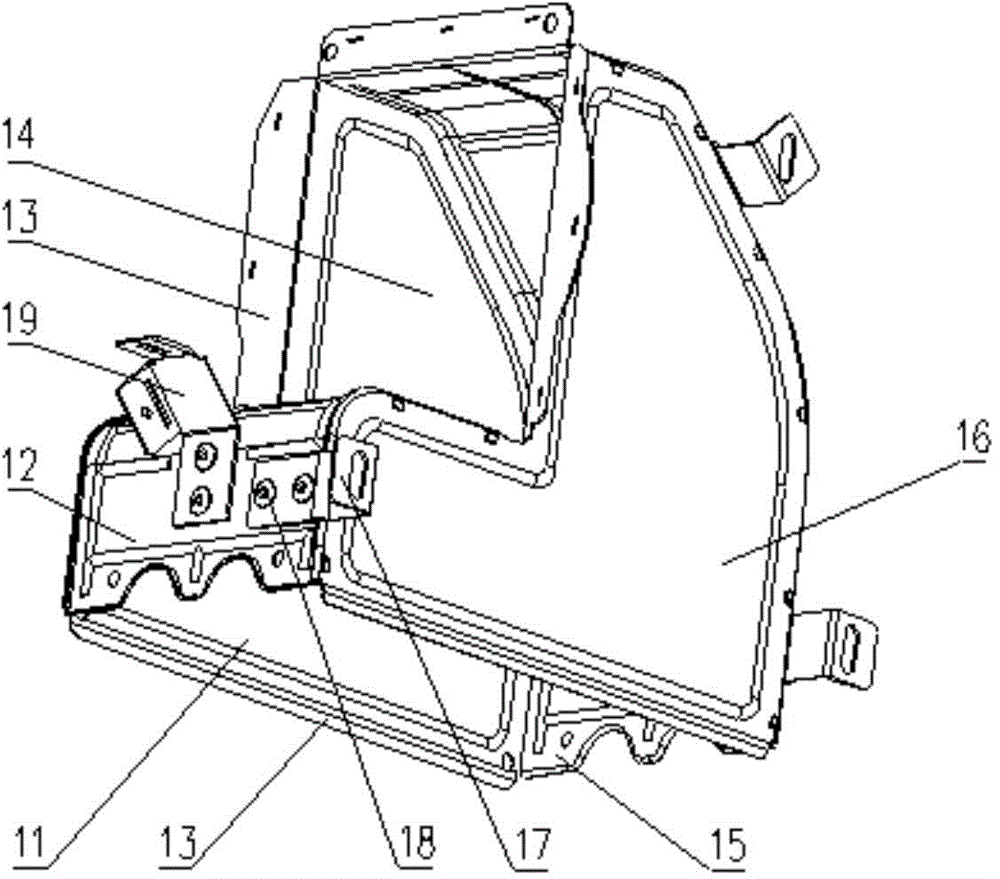

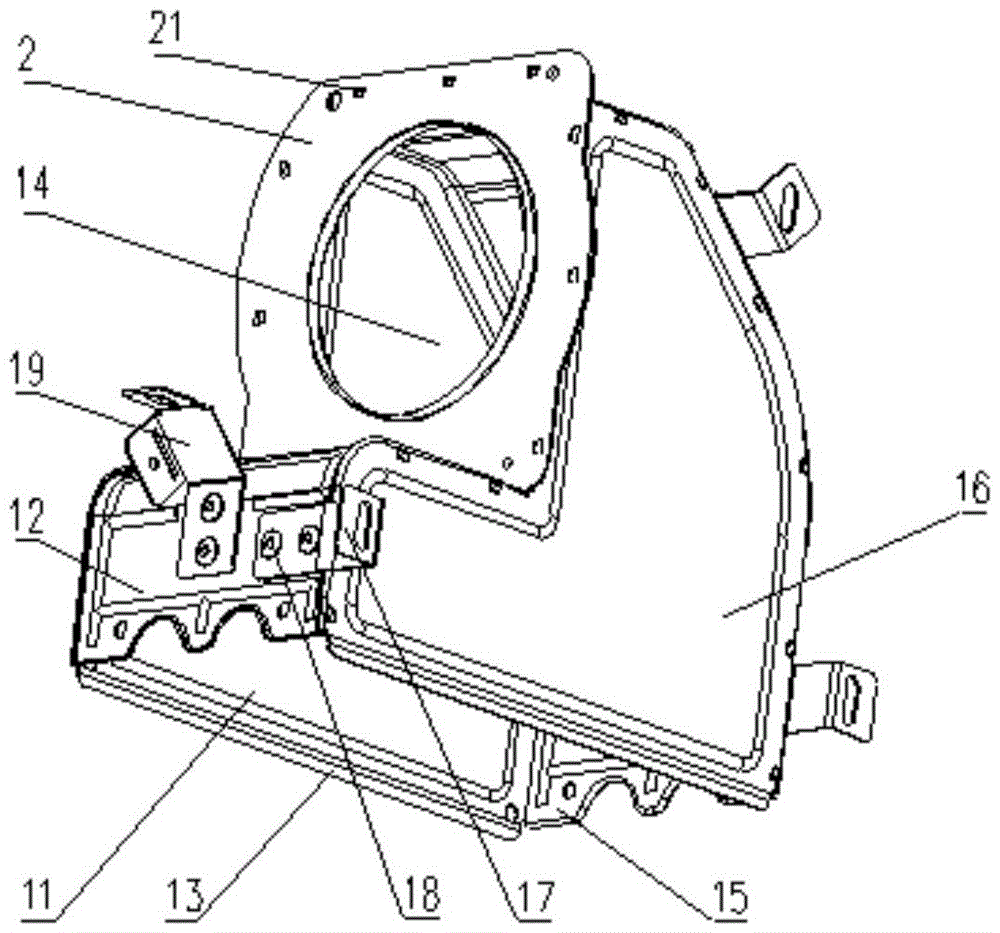

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the smoke inlet duct 1 includes a front side plate 12, a left side plate 13, a right side plate 16, a rear side plate 15, the top of the front side plate 12, the top of the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com