Optical switching device and straight-down type LED lamp with same

A technology of LED lamps and adapters, which is applied in the direction of optics, optical components, lighting devices, etc., can solve the problems of invaluability, high cost of flexible light source boards, certain problems in reliability and installation difficulty, and avoid graininess, The effect of compact structure and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The advantages of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

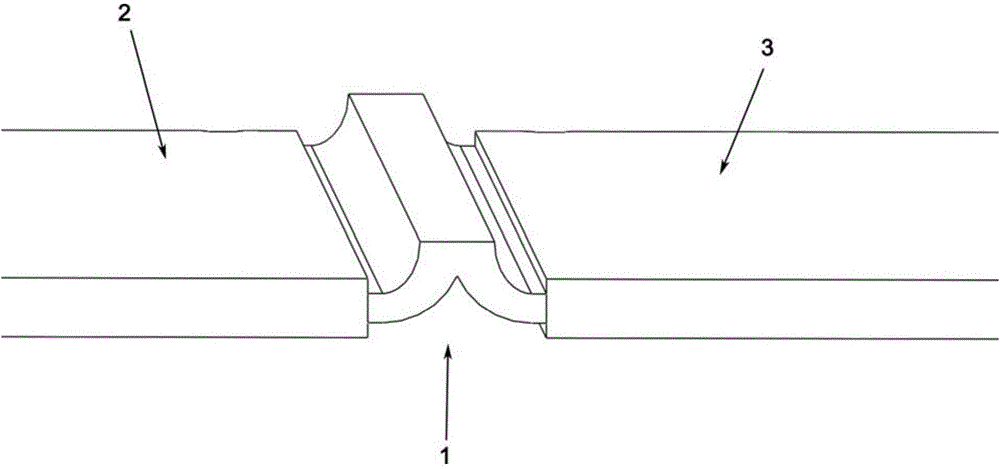

[0056] like figure 1 Shown is an optical transition device 1 according to a preferred embodiment of the present invention, which is used to deflect light into at least one light guide element, wherein the cross section of the optical transition device 1 is roughly "herringbone", mainly to The light emitted by the light source propagates to the adjacent light guide element through the reflection in the optical transition device 1 to realize surface emission.

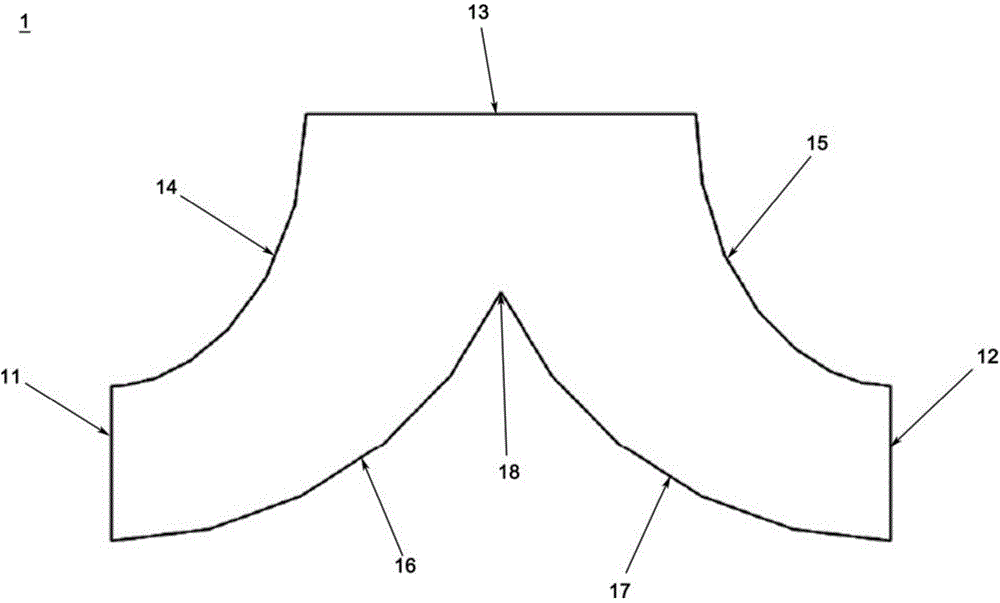

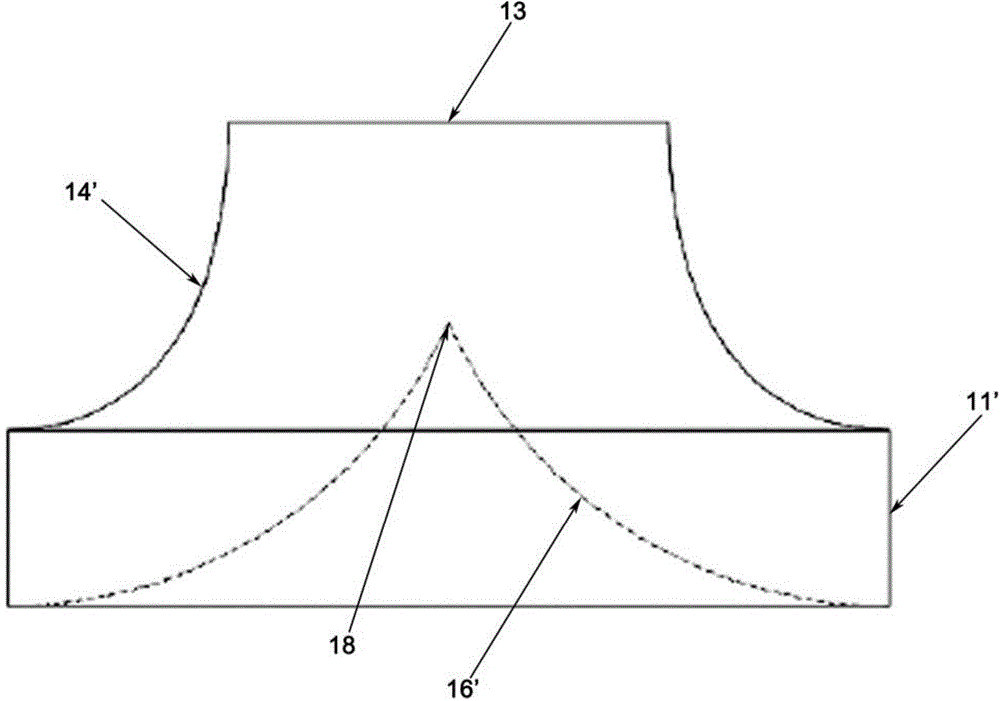

[0057] like figure 2 A schematic cross-sectional view of an optical transition device 1 according to a preferred embodiment of the present invention is shown, the optical transition device 1 includes opposite first and second surfaces, and light-emitting surfaces 11 and 12 connecting the first and second surfaces , the first surface includes the light incident surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com