Composite electrode, preparation method and uses thereof

A composite electrode and electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of limiting the output power of microbial fuel cells, low electron transfer efficiency, unfavorable promotion and application, etc., to improve electron transfer efficiency and bio-adhesion Quantity, preparation method is simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

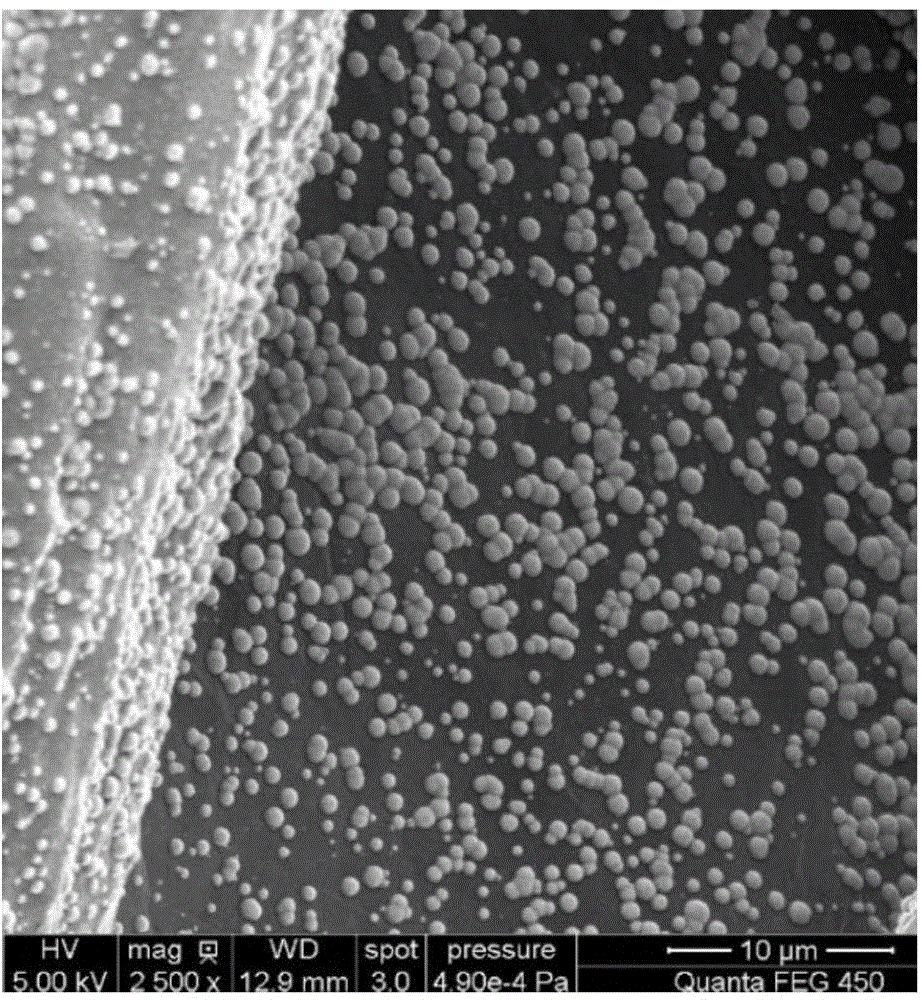

[0062] 1. Preparation method of stainless steel felt / graphene / manganese dioxide composite electrode

[0063] Using stainless steel felt as a conductive substrate, and graphene and manganese dioxide as active substances loaded on the surface of the conductive substrate, the steps for preparing a composite electrode are as follows:

[0064] (1) Using scissors, the stainless steel felt was cut into discs with a diameter of 3.8 cm, and then, after pretreatment with 20% acetone for 12 hours, it was dried at 60° C. for 12 hours.

[0065] (2) Ultrasonic disperse graphite oxide in deionized water to obtain a graphene oxide solution, ultrasonic conditions: power 400-600W, on for 5s and off for 5s, 90 times in total. After centrifugation, remove the supernatant suspension and dilute to a 1 mg / mL solution.

[0066] (3) Immerse the stainless steel felt in a 1 mg / mL graphene oxide solution for 15 minutes, take it out and dry it at 105°C, and then impregnate the dried stainless steel felt ...

Embodiment 2

[0079] The stainless steel felt / graphene / manganese dioxide composite electrode prepared in Example 1 was used as an anode to prepare a dual-chamber microbial fuel cell, and its performance was tested, as follows:

[0080] 1. Preparation of microbial fuel cells

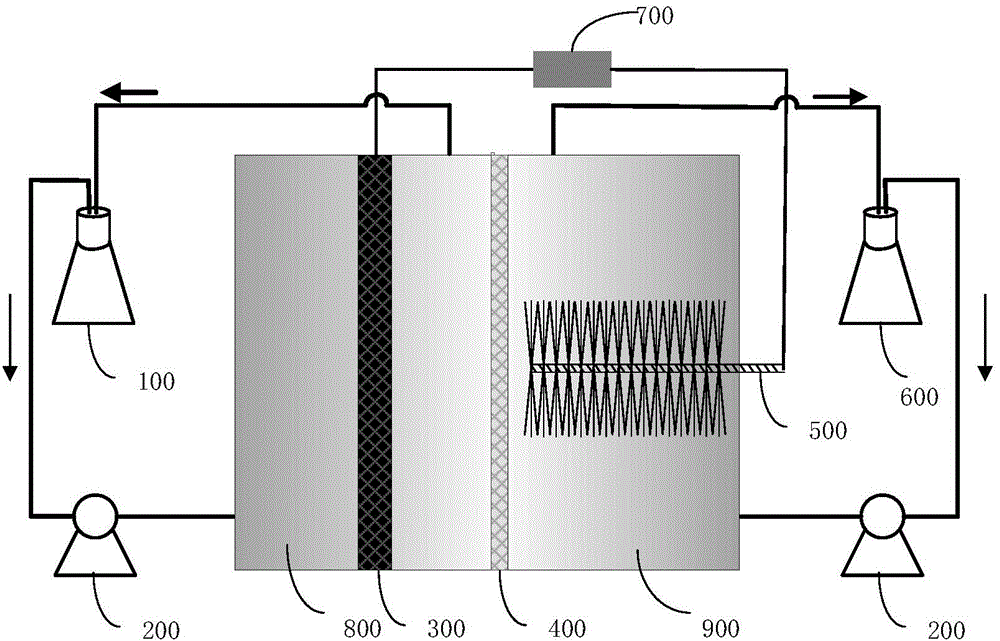

[0081] The stainless steel felt / graphene / manganese dioxide composite electrode that adopts embodiment 1 to prepare is as anode, with reference to figure 1 The structure of the microbial battery is shown, and a dual-chamber microbial fuel cell is prepared.

[0082] The specific structure of the dual-chamber microbial fuel cell is as follows: figure 1 Shown, wherein, 100 is the first circulating bottle, 200 is a peristaltic pump, 300 is an anode (stainless steel felt / graphene / manganese dioxide composite electrode), 400 is a cation exchange membrane, 500 is a cathode (carbon brush electrode), 600 700 is the external resistance, 800 is the anode chamber, 900 is the cathode chamber, and the direction of the arrow in the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap