Apparatus and method for in situ current measurement in a conductor

A technology of conductors and conductive structures, which is applied in the direction of measuring devices, measuring magnetic variables, measuring electrical variables, etc., and can solve problems such as occupying a large space, limiting high-precision current sensing, and being expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

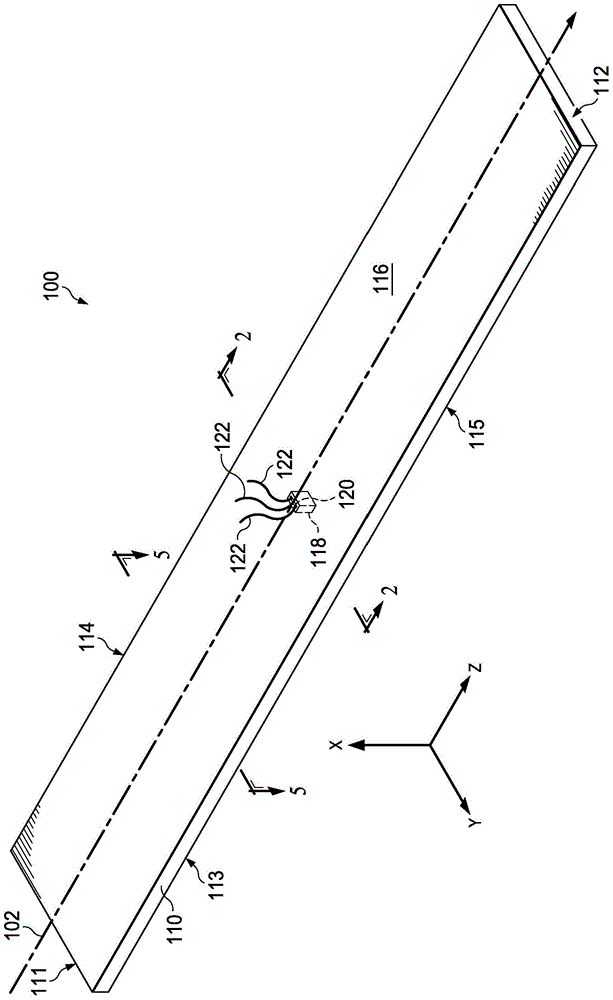

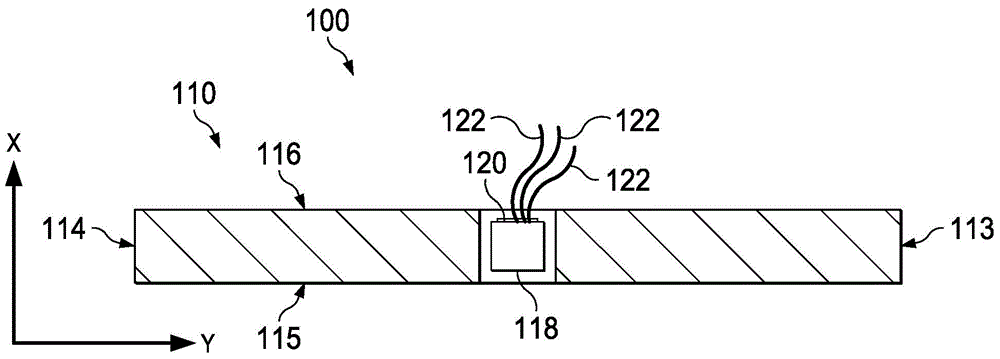

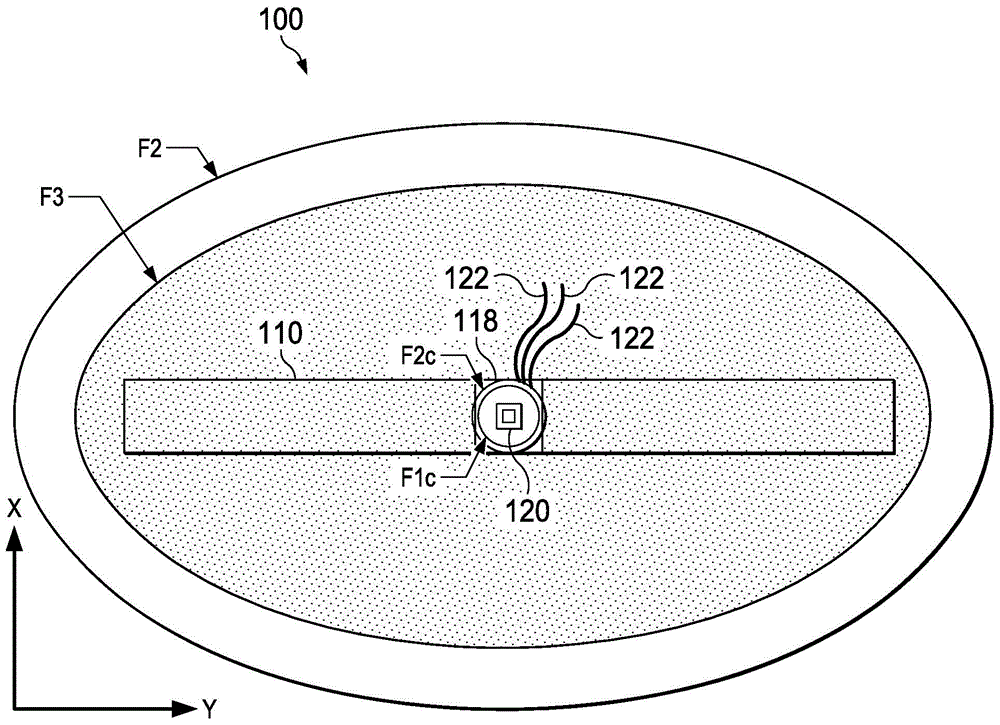

[0031] figure 1A conductor arrangement 100 is shown having an electrically conductive busbar structure 110 for conducting current in a longitudinal direction 102 . For reference only, the figures include examples of arrows representing X, Y, and Z coordinate axes. The illustrated longitudinal extent of the bus bar 110 is generally straight (eg, along the Z axis), although curved, serpentine, curvilinear or other longitudinal conductor structures 110 could be used. In the illustrated example, the busbar 110 includes first and second longitudinal ends 111 and 112, respectively, and has a generally rectangular shape with a periphery between the ends 111 and 112, the rectangular shape defined by a top surface or a second One side 116 , a bottom or second side 115 , and side opposing faces 113 and 114 are defined. The bus bar 110 includes a slot 118 extending inwardly of the top surface 116 in which a magnetometer or current sensor device 120 is positioned. In the illustrated ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com