Three-transmitting-coil coupling mechanism and magnetic coupling WPT system formed by three-transmitting-coil coupling mechanism

A technology of transmitting coil and coupling mechanism, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor core, transportation and packaging, etc., can solve the problem of reducing system output power and efficiency, low output power, prolonging charging Time and other issues, to achieve the effect of improving anti-offset capability, reducing system cost and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0030] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

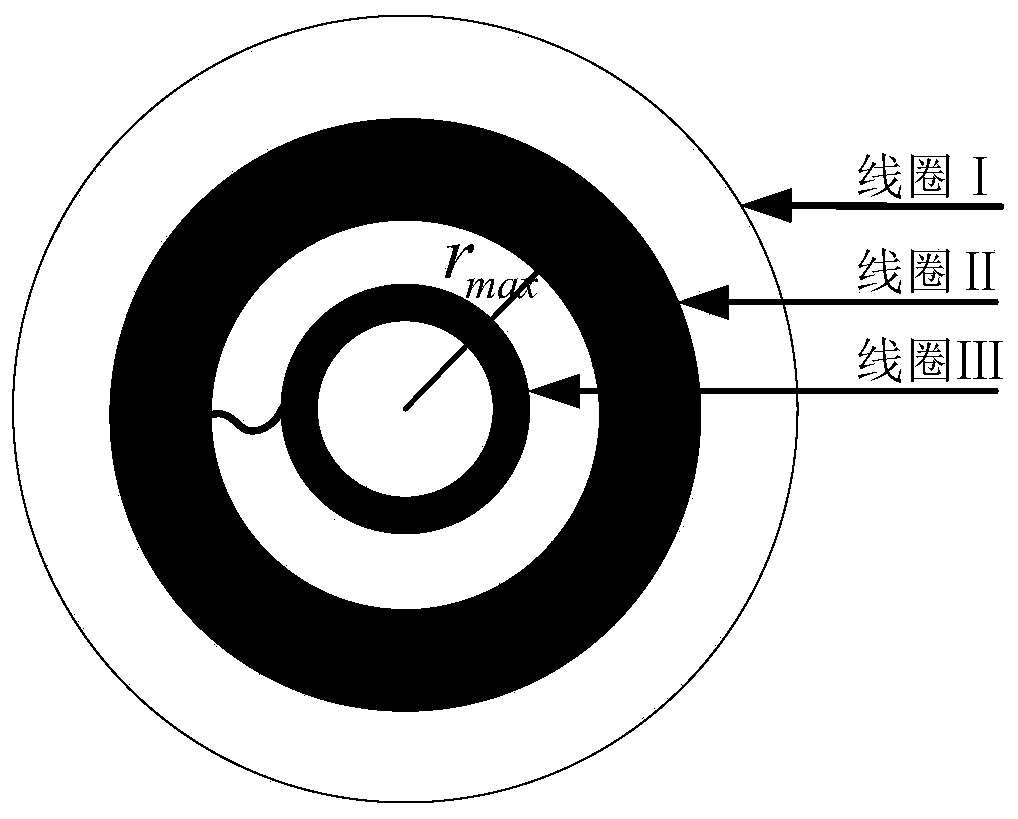

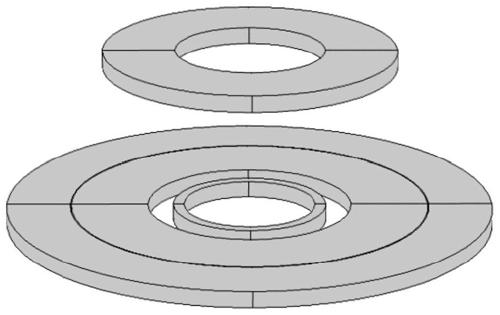

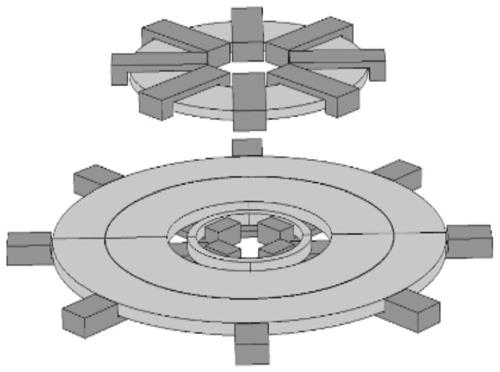

[0031] Such as figure 1 As shown, the present embodiment provides a coupling mechanism with three transmitting coils, the transmitting end includes a first coil (coil I), a second coil (coil II) and a third coil (coil III), and the first coil is composed of A single wire is wound to form a multi-turn coil and constitutes a peripheral charging area, and the second coil and the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com