Automobile integrated skin method and its mold structure

An all-in-one, automotive technology, applied in the superstructure, superstructure sub-assemblies, forming tools, etc., can solve the problems of scrapped side skins, complex process flow, material cost, etc. Simple, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

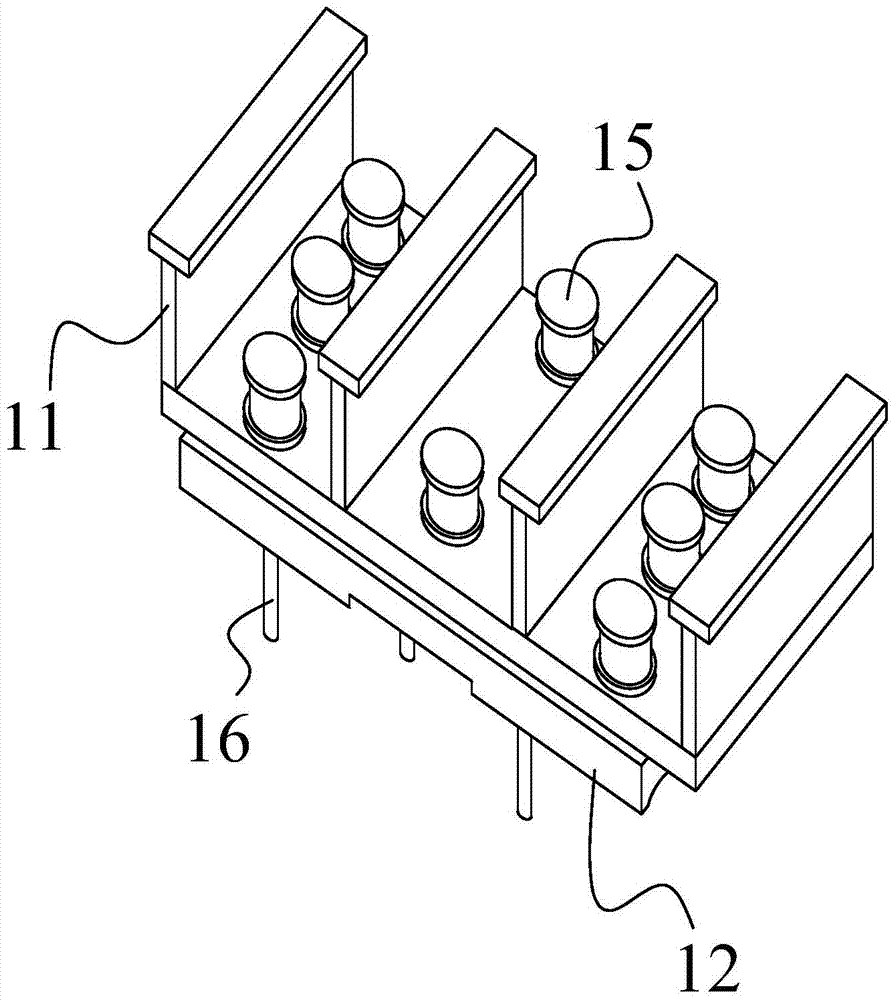

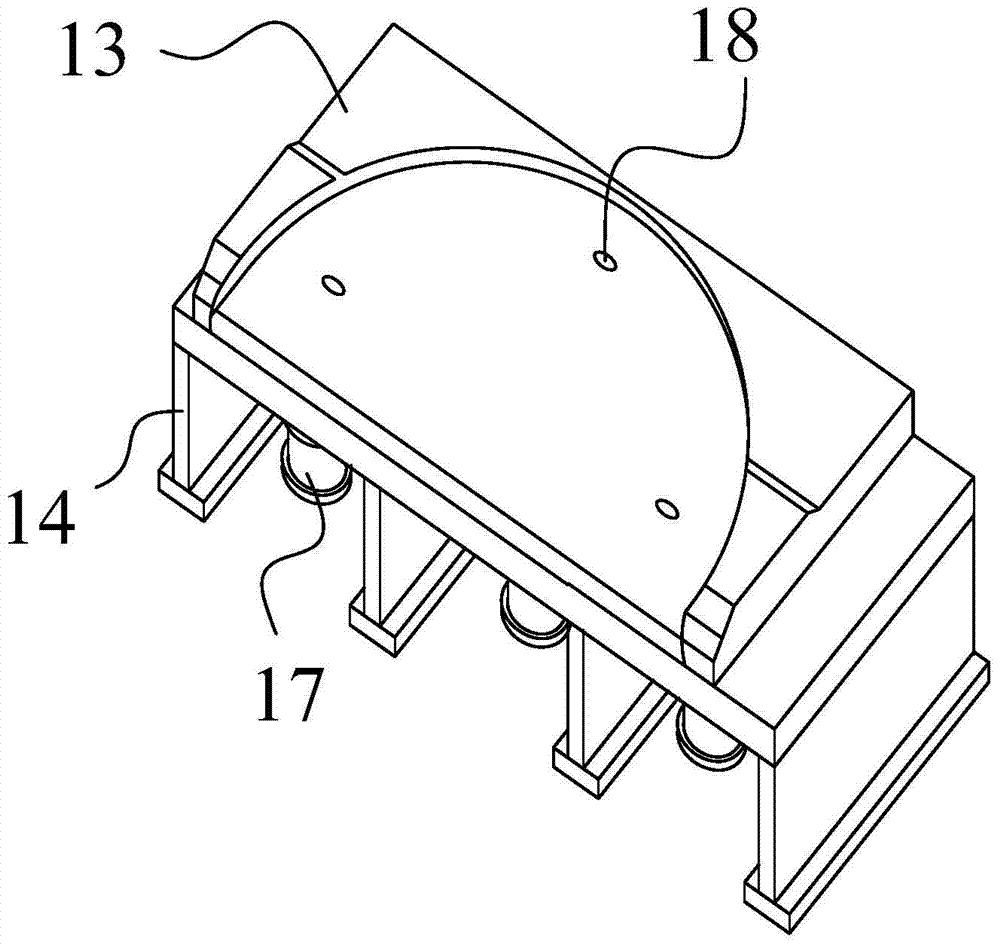

[0026] Embodiment 1. A process and mold structure of an automobile integrated skin are provided.

[0027] Its automotive one-piece skin processing method includes three steps: roll forming, cutting forming, and hydroforming:

[0028] Roll Forming:

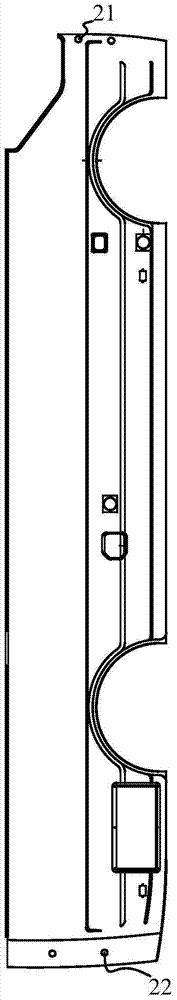

[0029] Such as figure 1 As shown, the roll forming step is a step of forming for the cross-sectional shape of the side skin. Due to the different types, models, and sizes of automobiles, the cross-sectional shape of the shell is also different. Therefore, it is necessary to set the cross-sectional shape in advance for each roll forming. According to the cross-sectional shape, set the plate roller Relevant parameters of the press (relevant parameters here refer to the relevant parameters of the cross-sectional shape of the car skin. Because the types of cars are different, the skin cross-sectional shapes are also different, so before each operation, according to the car’s The general category sets the corresponding shape of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com