Automatic concrete curing device

A curing device and concrete technology, applied in the field of concrete automatic curing device, can solve the problems affecting concrete strength, maintenance interruption, moisturizing maintenance interruption, etc., and achieve the effect of reducing dead corners and blind spots, improving utilization efficiency, and facilitating operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the text of the description.

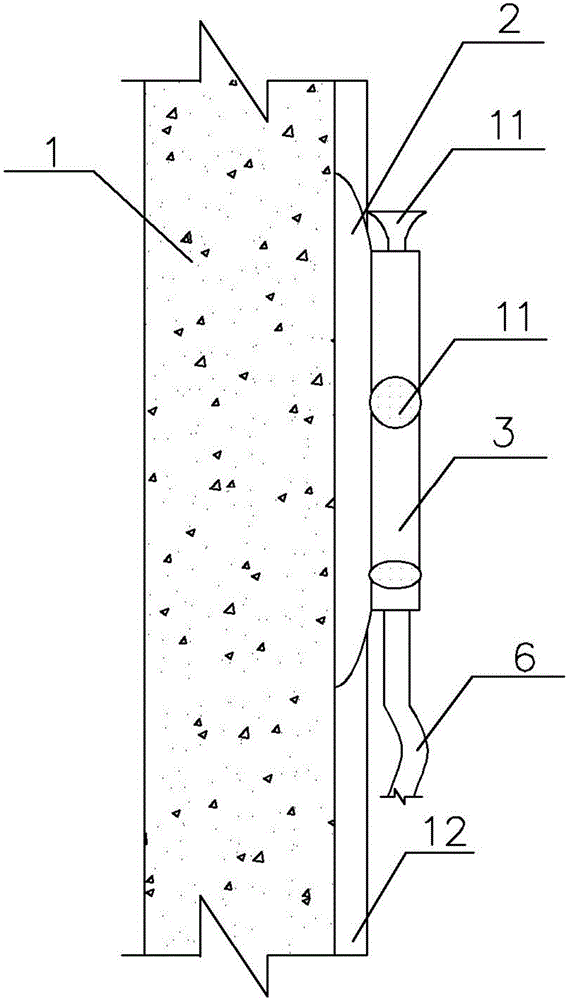

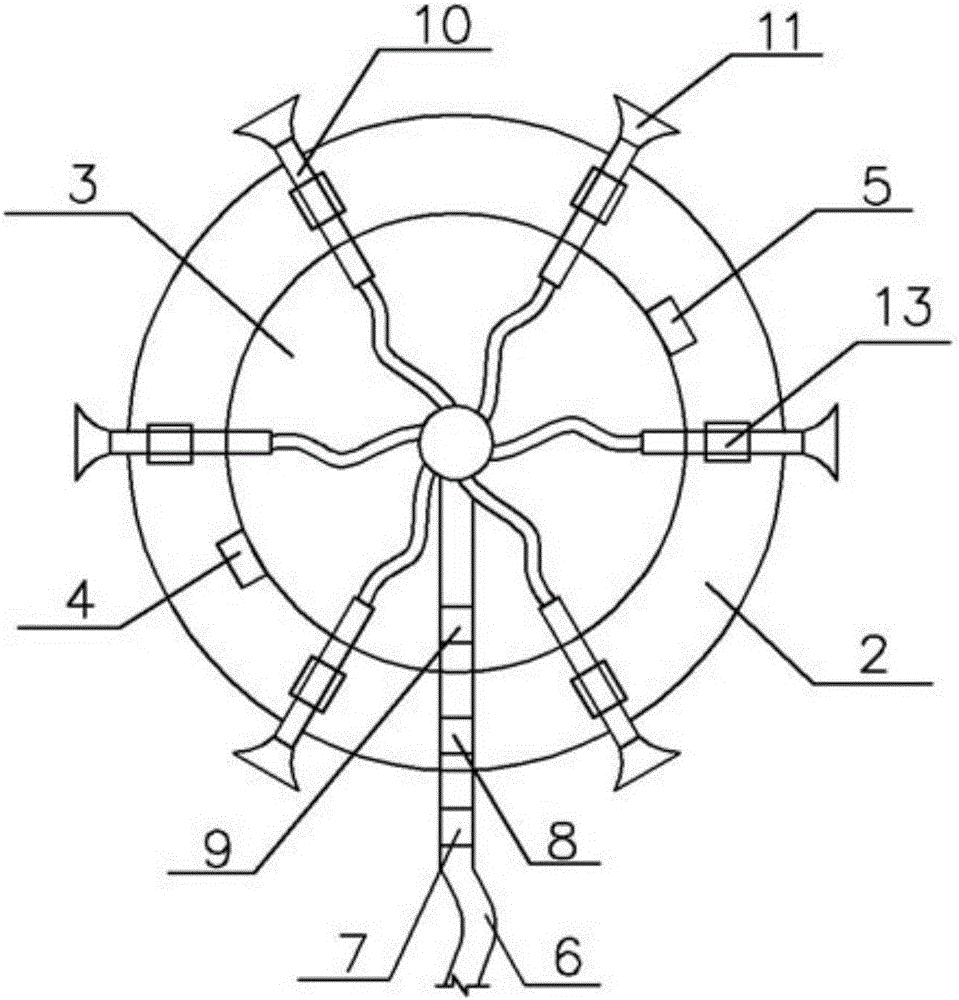

[0035] Such as Figure 1~2 As shown, the present invention provides an automatic concrete curing device, including:

[0036] Suction cup 2, the first side of which can be adsorbed on the concrete structure 1 to be cured;

[0037] The working disk 3 defines a cavity inside, the bottom of the working disk 3 is fixed on the side of the suction cup 2 opposite to the first side, and the top of the working disk 3 is provided with an openable / closable cover, so A first temperature sensor 4 for sensing the temperature of the concrete structure 1 is provided in the cavity, and a humidity sensor 5 is provided on the outside of the working plate 3;

[0038] The first end of the water inlet pipe 6 is in communication with a water source, and the second end of the water inlet pipe 6 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com