Heavy-duty vehicle shock absorber

A shock absorber and vehicle technology, applied in mechanical equipment, springs/shock absorbers, springs, etc., can solve the problems affecting the speed of construction site, high labor cost, high labor intensity, etc., to improve work efficiency, save labor, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

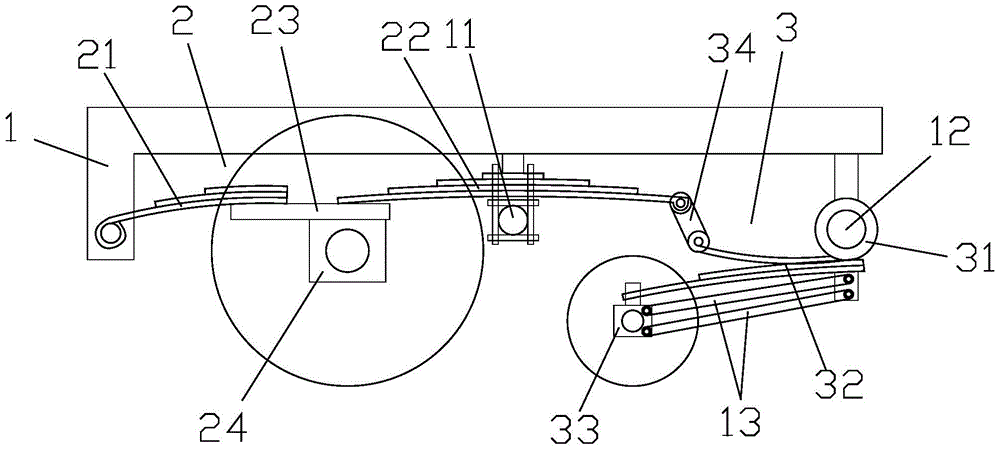

[0019] The load-carrying vehicle shock-absorbing mechanism of the present invention, as figure 1 Said, including a vehicle frame 1, a main cross shaft 11 is installed on the vehicle frame 1, and a main suspension mechanism 2 is installed on both sides of the vehicle frame 1.

[0020] The main suspension mechanism 2 includes a swing leaf spring 21 , a support leaf spring 22 and a connecting frame 23 .

[0021] The connecting frame 23 is located at the front side of the main transverse shaft 11, the supporting leaf spring 22 is installed on the main transverse shaft 11, and is connected with the connecting frame 23, and the front part of the vehicle frame 1 is connected with the connecting frame 23 through the swinging leaf spring 21 Swing leaf spring 21 is hinged with vehicle frame 1,

[0022] A main axle 24 is installed between the connecting frames 23 of the two main suspension mechanisms 2, and the main axle 24 is installed with main wheels. The connecting frames 23 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com