Deepwater manned submersible and pressure-resistant processing method for submersible components

A technology for manned submersibles and submersibles, which is applied in the directions of underwater operation equipment, transportation and packaging, ships, etc., can solve the problems of fuel consumption, complex structure of the ups and downs control system, and low safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

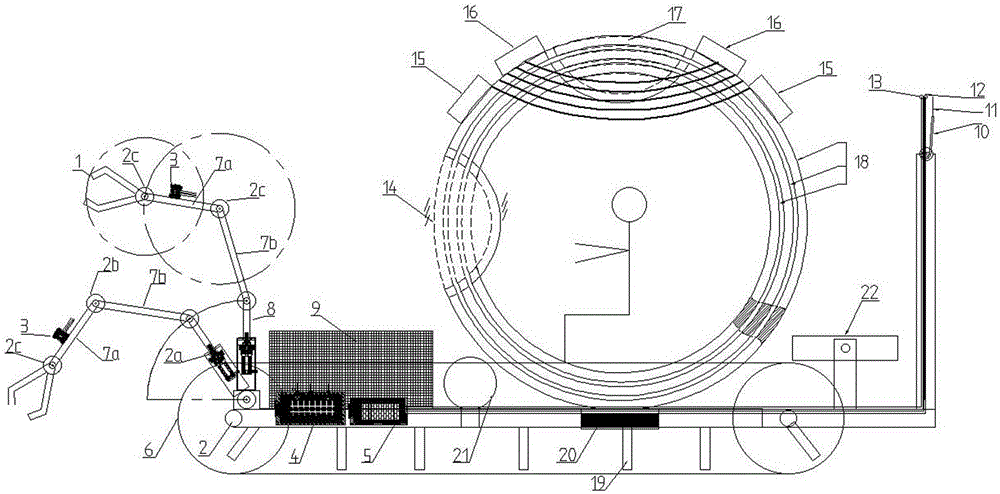

[0024] Such as figure 1 As shown, a deep-water manned submersible includes a submersible and a mother ship, and the submersible is connected with the mother ship. , communication equipment, variable speed motor, walking crawler 6, universal propeller 23, water spray device, self-unloading device 20 and self-rescue device; the two sides of the frame are provided with walking crawler 6; the manipulator 1 passes through the variable speed motor I2a The connection is fixed at the front end of the frame; the collection box 9 is fixedly installed on the frame; the backup battery 4, communication equipment and integrated circuit 5 boards are installed and fixed below the collection box 9; the universal propeller 23 is fixedly installed At the rear of the frame, the manned cabin 18 is located between the universal propeller 23 and the collection box 9 and is fixed on the frame by the self-unloading device 20, and a water spray device is provided between the manned cabin 18 and the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com