An unsealable screen hanger

A technology of hanger and screen pipe, which is applied in wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of difficulty in unsealing and heavy unsealing load, and achieve safe and smooth unsealing, small unsealing force and satisfactory operation effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

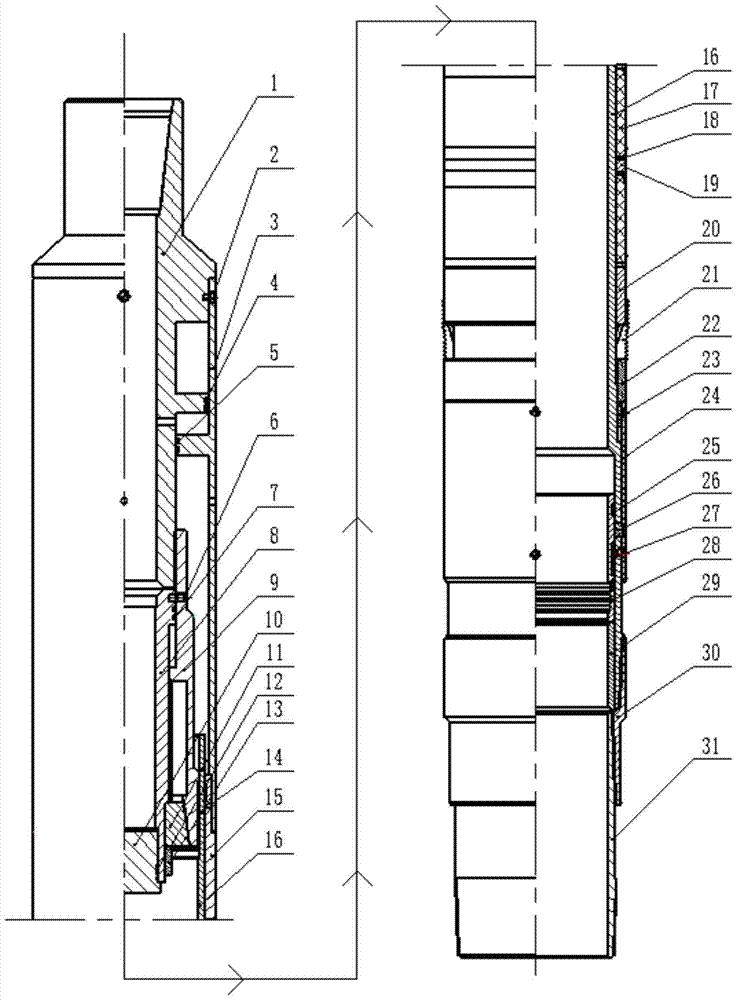

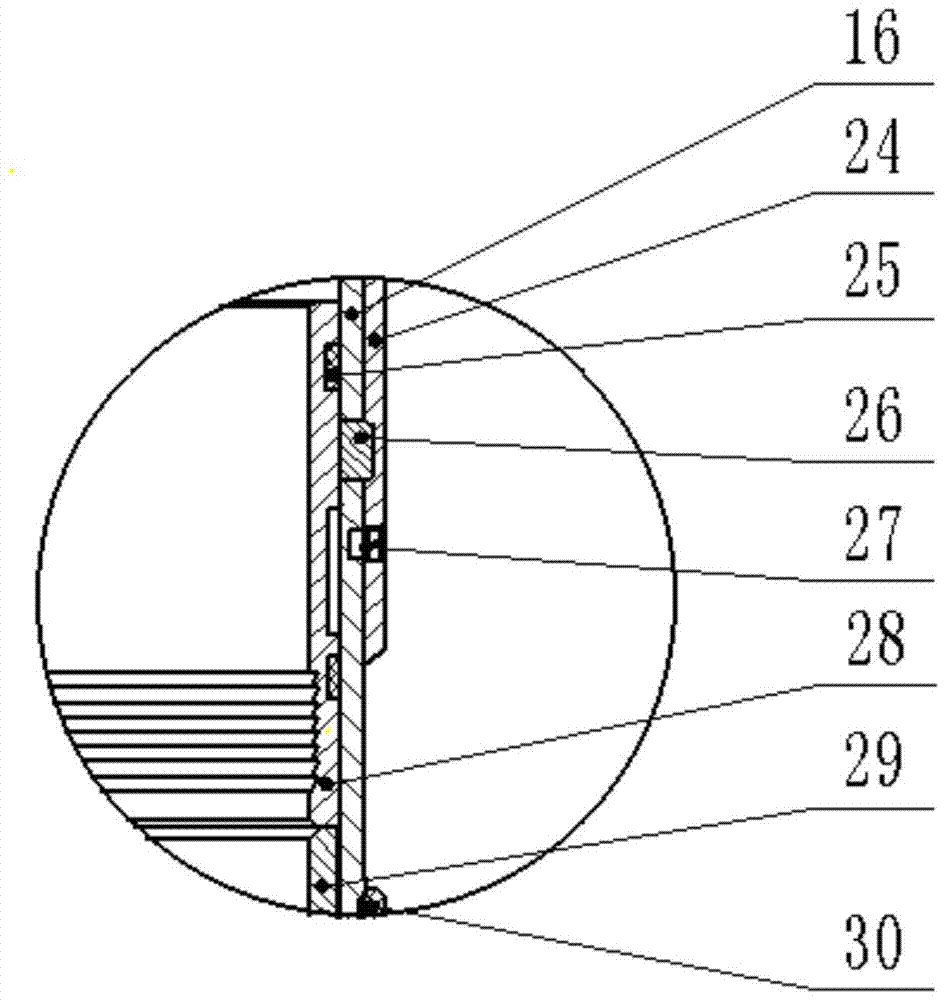

[0015] Such as figure 1 , figure 2 As shown, a de-sealable screen hanger includes an upper joint 1, a piston cylinder 3, a central tube 16 and a lower joint 31; the upper end of the piston cylinder 3 is connected to the outer wall of the upper joint 1 through a setting shear nail 2. The upper joint 1. A boss is provided on the outer wall and the boss is sealed with the inner wall of the piston cylinder 3 through a sealing ring I4. A boss is provided on the inner wall of the piston cylinder 3 and the boss is sealed with the outer wall of the upper joint 1 through a sealing ring II5. The upper joint 1 side The wall is provided with a communication hole that communicates with the space between the boss of the upper joint 1 and the boss of the piston cylinder 3, and the side wall of the lower end of the piston cylinder 3 is provided with a pressure relief hole. The outer wall of the lower end of the upper joint 1 is threadedly connected. The claw spring 9, the lower end of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com