An experimental device for mass-separation and directional fracturing

An experimental device and fracturing technology, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling, etc., can solve the problems of failure to provide guidance and help, failure to simulate mine test fracturing, damage to the continuity of the experimental plan, Integrity and other issues to achieve effective regulation and monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

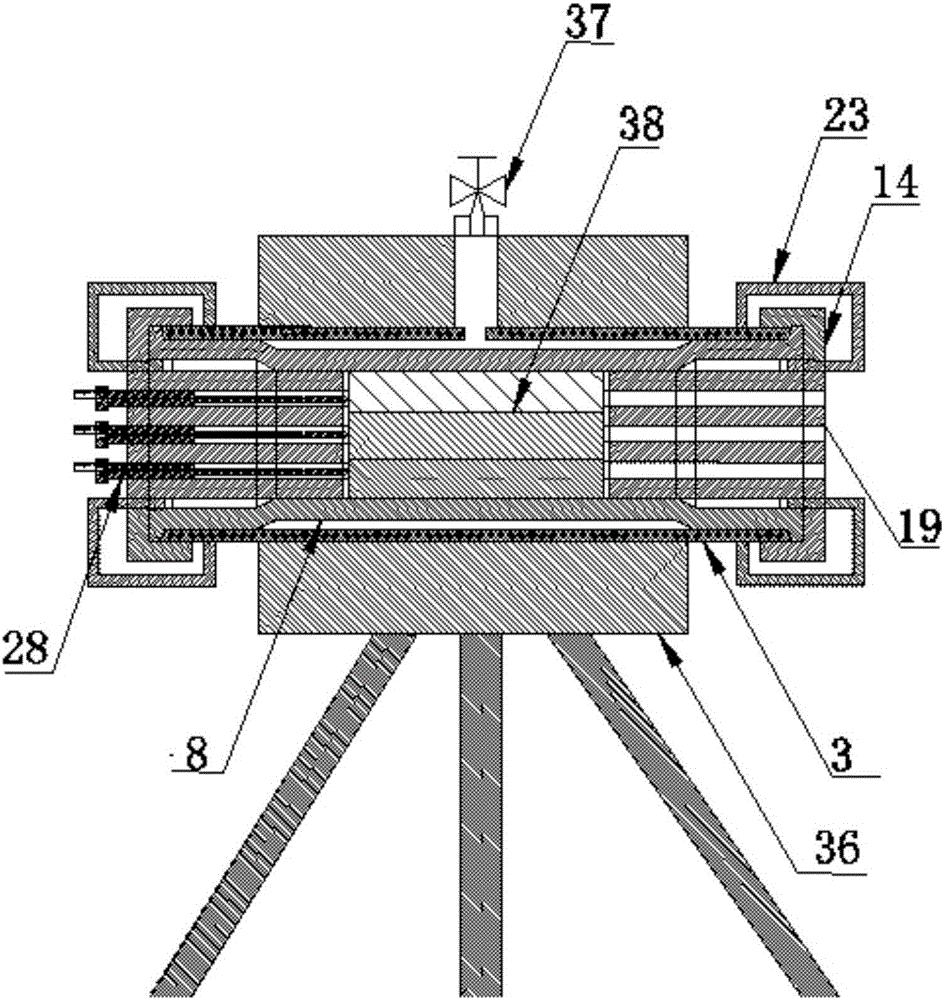

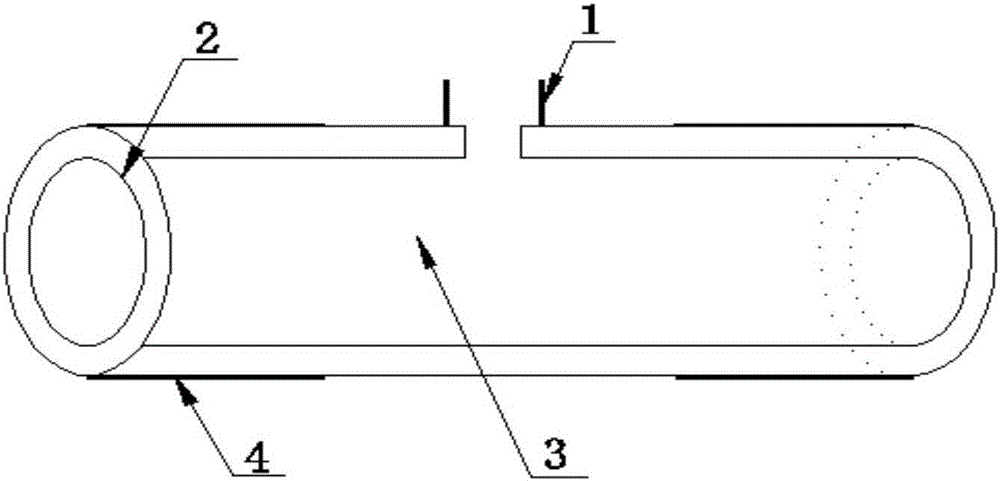

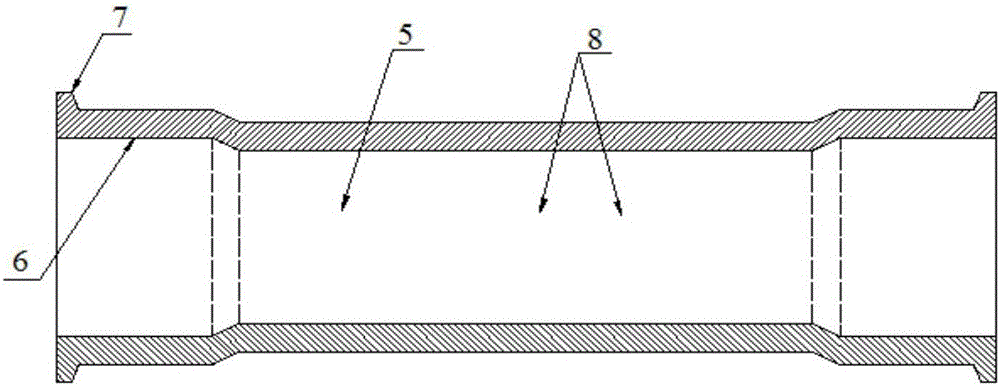

[0038] The structure of the mass-separation-separation directional fracturing experiment device is as follows: figure 1 As shown, it includes a stainless steel cylinder 3, a plug regulator 23, a pressure-resistant sealing rubber sleeve 8, a sealing pressure ring 14, an adjustable plug 19 with a displacement channel, a core fracturing device 28, and a base 36. The pressure-resistant sealing rubber sleeve 8 is embedded in the stainless steel cylinder 3, and the two ends of the stainless steel cylinder 3 and the pressure-resistant sealing rubber sleeve 8 are pressed tightly with the sealing pressure ring 14; the exposed core model is placed in the pressure-resistant sealing rubber sleeve 8;

[0039] Two adjustable plugs 19 are respectively inserted at the two ends of the pressure-resistant sealing rubber sleeve 8, and a plug regulator 23 is installed outside the adjustable plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com