Construction method for connecting main structure and secondary structure of hook face

A construction method and main structure technology, applied in the direction of building structure, construction, etc., can solve problems such as ineffective connection and error, and achieve the effects of simple installation, saving construction period and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

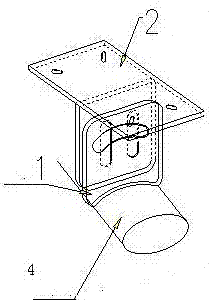

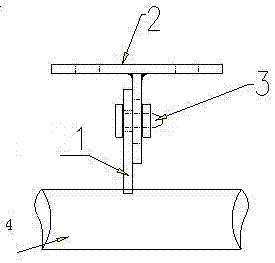

[0018] See figure 1 with figure 2 , A construction method for connecting a curved main structure and a secondary structure, which includes the following steps:

[0019] The connecting piece processing steps; including the connecting plate 1 welded on the main structure 4 and the T-shaped plate 2 connected with the connecting plate; the bottom of the connecting plate is processed to match the curvature of the curved main structure to facilitate the welding and connection of the two, and the middle part is opened. The horizontal arc-shaped long waist-shaped hole, and the longitudinal long waist-shaped hole is opened on the web of the T-shaped plate;

[0020] Curved positioning welding steps;

[0021] The curved surface positioning step is mainly based on the positional relationship between the secondary structure and the main structure, welding the connecting plate and the main structure, and positioning and welding the intermediate transfer in turn according to the interval;

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com