A method of an interior experimental device and using this device for section

An experimental device and an integrated technology, applied in the field of profile control devices, can solve the problem of inability to realize precise profile control of hypertonic strips, inability to give accurate guidance and assistance on site, and inability to judge basic parameters such as the position and size of hypertonic strips, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

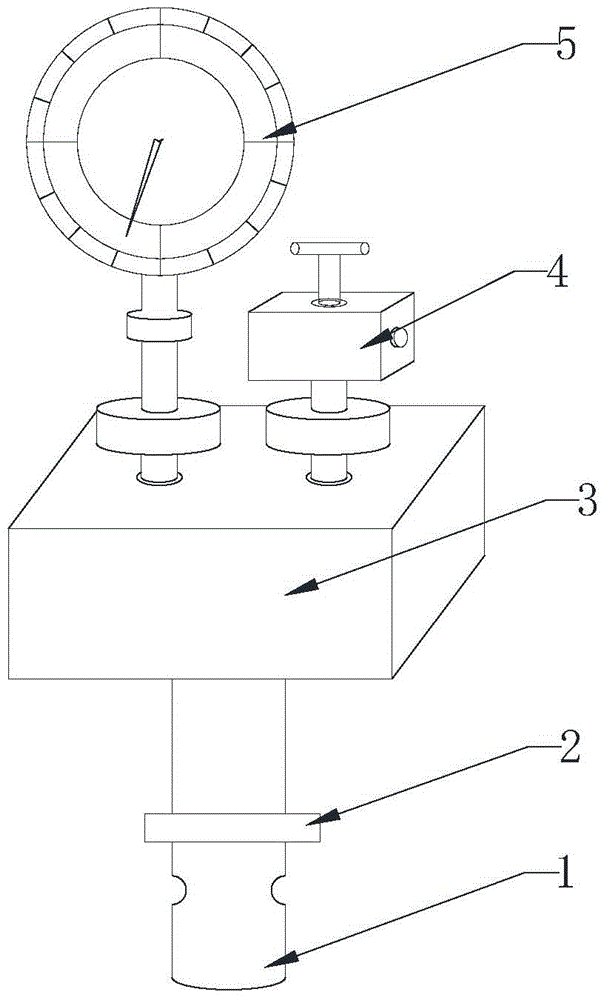

[0034] 1. Manufacture of pressure measurement, injection and production integrated instrument

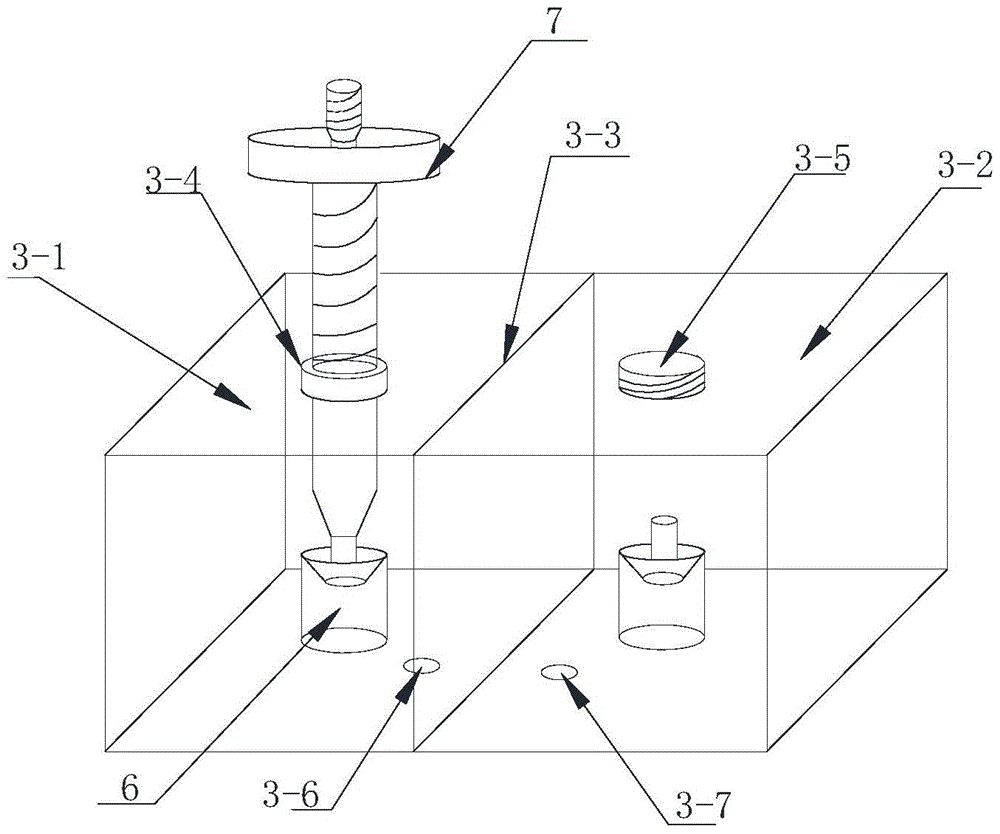

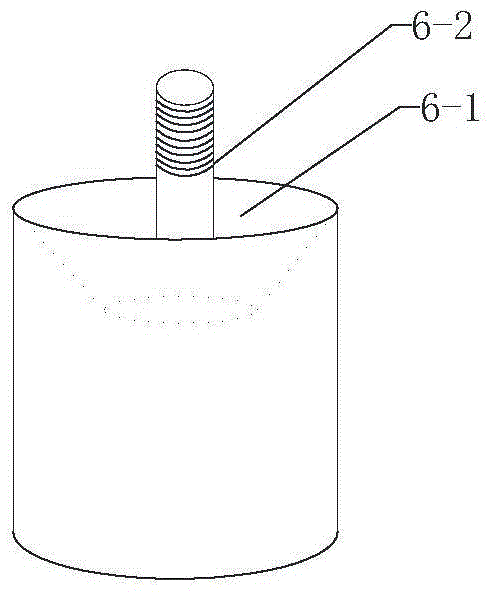

[0035] The integrated instrument for pressure measurement, injection and production is an instrument that can realize pressure monitoring and displacement fluid injection and production at a certain point at the same time. Figure 1A combine Figure 1B As shown: the main body of the instrument is a cuboid container 1 with a length of 50 mm, a width of 25 mm, a height of 25 mm, and a wall thickness of 7 mm. The container has a built-in baffle 3-3, and the baffle 3-3 divides the container evenly into the left chamber 3-1 and The right chamber 3-2, the liquid inside the two chambers cannot cross-flow; the left chamber 3-1 and the center of the upper end surface of the right chamber 3-2 are respectively provided with a left bolt hole 3-4 and a right bolt hole 3-4 with a diameter of 5 mm. Bolt holes 3-5, left chamber 3-1 and right chamber 3-2 are symmetrically arranged on the lower end s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com