A temperature-controlled telescopic tube

A technology of temperature-controlled telescopic tubes and bellows, which is applied in the direction of valve details, engine components, valve operation/release devices, etc., can solve problems such as small expansion range, complex internal structure of one-way heat transfer valve, and not easy to be small , to achieve the effect of large expansion and contraction, simple structure and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

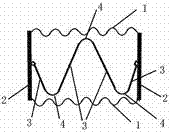

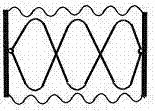

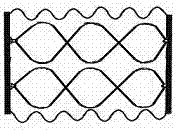

[0009] figure 1 It is a schematic diagram of the basic structure of the present invention. Both sides of the bellows 1 are heat conduction plates 2, and the zigzag shape curve formed by the curved bimetal 4 and the straight rod 3 that is axially connected between the heat conduction plates 2, the number of the curves is 1; figure 2 Among them, the number of zigzag-shaped curves composed of curved bimetallic sheets 4 and straight rods 3 that are axially connected between the heat conducting plates 2 is 2. Under the same internal material and external temperature, figure 2 compared to figure 1 The type variables are the same, but the deformation force is doubled; image 3 Among them, the number of zigzag-shaped curves composed of curved bimetallic sheets 4 and straight rods 3 that are axially connected between the heat conduction plates 2 is 4, which is suitable for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com