Dehumidification and rust-prevention device for marine diesel engine

A marine diesel engine and fan technology, applied in the electromechanical field, can solve the problems of unable to start the dehumidifier in time, the air cannot be circulated, and the humidity control cannot be achieved, and achieve the effect of simple structure, high reliability and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention cannot be limited thereby.

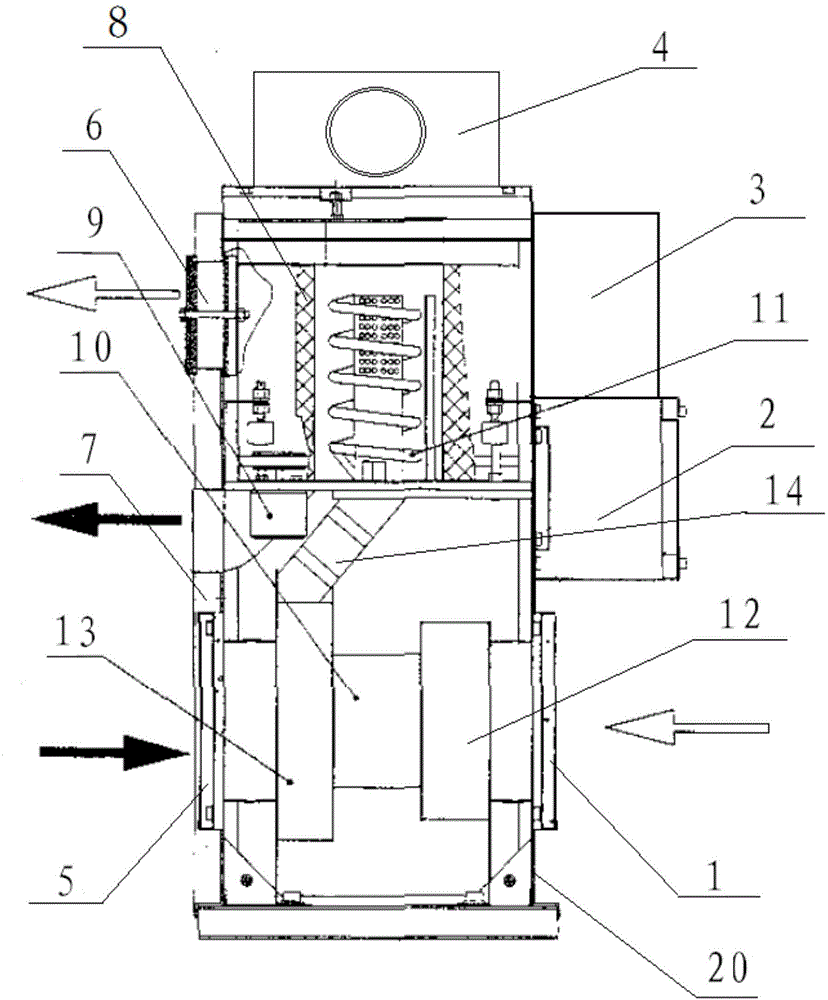

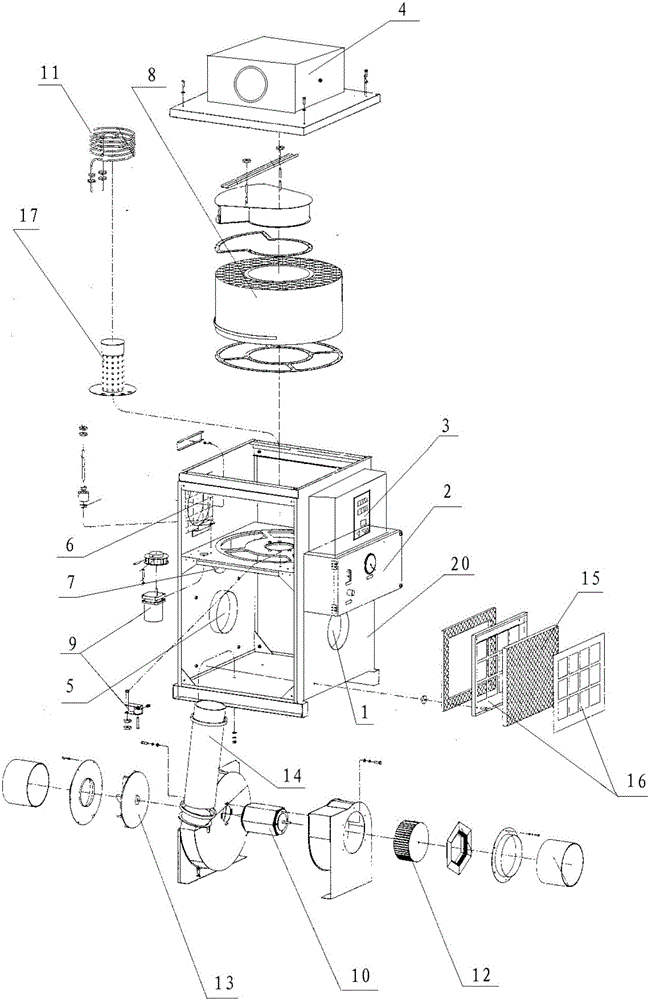

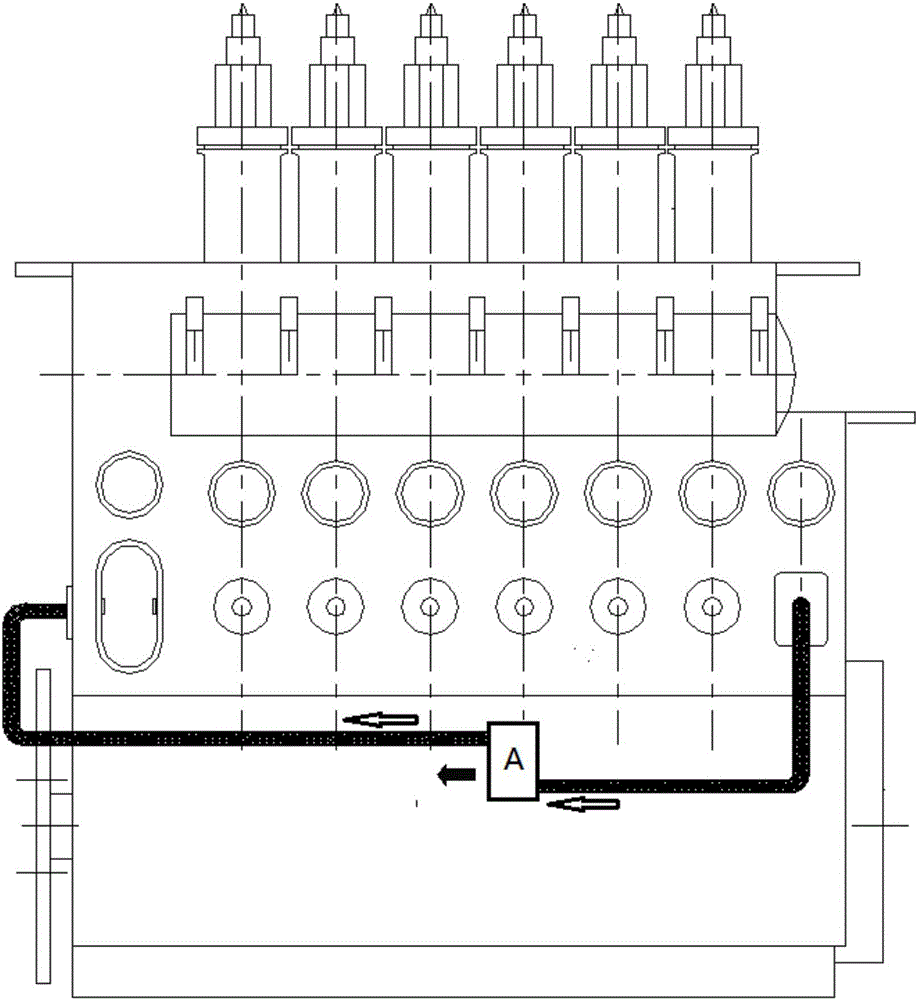

[0027] Please refer to figure 1 and figure 2 , the dehumidification and anti-rust device for marine diesel engine includes chassis 20, treatment air inlet 1, electrical control box 2, temperature and humidity display controller 3, humidity temperature sensor box 4, regeneration air inlet 5, dry air outlet 6, humidity Air outlet 7, drying runner 8, runner drive part 9, fan motor 10, regeneration air heater 11, processing fan 12 and regeneration fan 13; among them, processing air inlet 1, electrical control box 2 and temperature and humidity display controller 3 is arranged on the front side of the cabinet 20, the humidity and temperature sensor box 4 is arranged on the top of the cabinet 20, the regeneration air inlet 5, the dry air outlet 6 and the wet air outlet 7 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap