Profile transition method based on female cam coarse grinding

A profile and cam technology, applied in the direction of electrical program control, digital control, etc., can solve the problems of low follow-up processing efficiency, high complexity, and uneven cam profile, so as to improve the efficiency of rough grinding and uniform finish machining volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

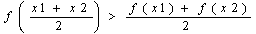

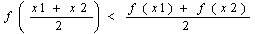

[0025] see figure 1 and figure 2 , the present invention discloses a profile transition method based on the rough grinding of the female cam, the core principle of which is to use the definition of the concave-convex function to find out the convex interval (not unique) on the original profile of the female cam through calculation, and to use a smooth Curve 2 (without excluding straight lines, e.g. figure 1 The straight line BG in ) replaces the original profile 1 located between the two ends of the smooth curve to form a new profile of the female cam. The line is tangent (ie, the smooth curve and the original profile have a common tangent at the point of tangency). The smooth curve has no inflection point, and when the smooth curve is concave towards the inside of the cam body, its radius of curvature should be greater than the radius of the grinding wheel for grinding.

[0026] If there are more than two convex intervals, the convex intervals can be grouped in pairs, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com