Thin-walled catheter machining method

A thin-walled conduit and machining technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of easy jumping of parts, uneven force on tools, waste of raw materials, etc., and achieve the guarantee of coaxiality of parts , Improve the processing pass rate, improve the effect of product pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below through the following specific examples.

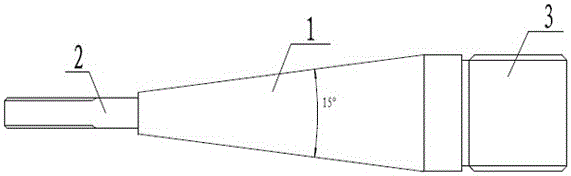

[0020] see figure 1 , figure 2 , image 3 The thin-walled catheter mechanical processing method, its specific steps are as follows:

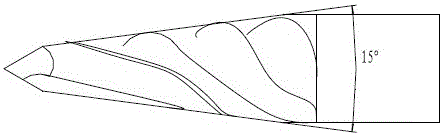

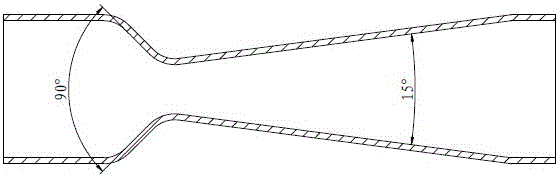

[0021] 1) Prepare three tapered drill bits with a 15° cone angle and one tapered drill bit with a 90° cone angle of different specifications and a mandrel matching the geometry of the lumen of the thin-walled catheter;

[0022] 2) Process a blind hole with a diameter of Φ15 and a depth of about 90mm at one end of the thin-walled conduit blank;

[0023] 3) Process a hole with a diameter of Φ15 at the other end of the thin-walled catheter blank until it is drilled through;

[0024] 4) Use the tapered drill with a 15° cone angle and the tapered drill with a 90° cone angle prepared in step 1) to start roughing the lumen of the thin-walled catheter blank;

[0025] 5) After the inner cavity of the thin-walled catheter blank is processed in step 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com