An automatic milling method for high-precision blind holes

A milling and high-precision technology, applied in the field of mechanical processing, can solve problems such as the inability to meet the precision requirements of flat-bottomed hanging holes, the inability to produce blind holes, and hidden quality problems, so as to avoid manual intervention, uniform finishing allowance, and guarantee The effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions for realizing the object of the present invention are further described below through several specific examples. It should be noted that the technical solutions claimed in the present invention include but are not limited to the following examples.

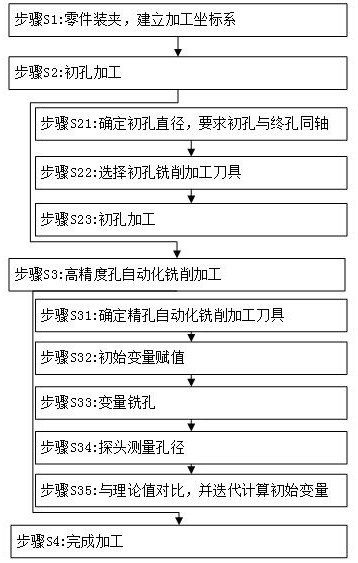

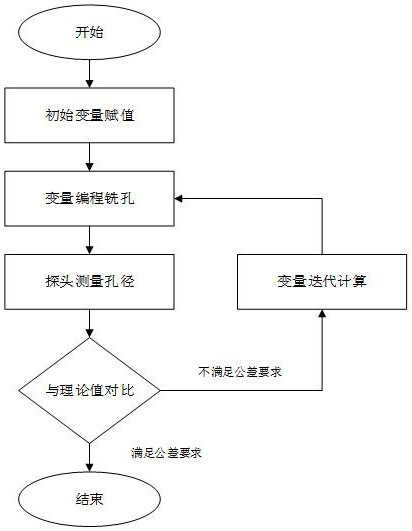

[0036] As one of the most basic implementations of the present invention, this embodiment discloses an automatic milling method for high-precision blind holes, including the following steps:

[0037] Step S1, select a vertical milling machine or a horizontal milling machine as a processing machine tool, clamp the parts to be processed, and establish a processing coordinate system.

[0038] Step S2, initial hole processing; specifically includes:

[0039] Step S21, determine the diameter of the initial hole as φ f , the diameter of the final hole is φ, the diameter of the initial hole and the final hole should meet: φ-φf≥1mm, and the initial hole and the final hole are coaxial;

[0040] Step S22, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com