Sag observation method for power transmission line engineering construction

A technology for engineering construction and transmission lines, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as technical personnel safety hazards, design stress value errors, etc., and achieve the effect of simple control of line stress

Active Publication Date: 2015-10-21

CHINA THREE GORGES UNIV

View PDF4 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0012] (1): In special areas such as mountains and jungles, no sag can be observed on the tower and under the tower of the overhead line, which brings challenges to the safety of the operating stress of the overhead line, and the traditional method is no longer applicable

[0013] (2): The essence of the traditional sag observation method is to directly observe the sag. There is alrea

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

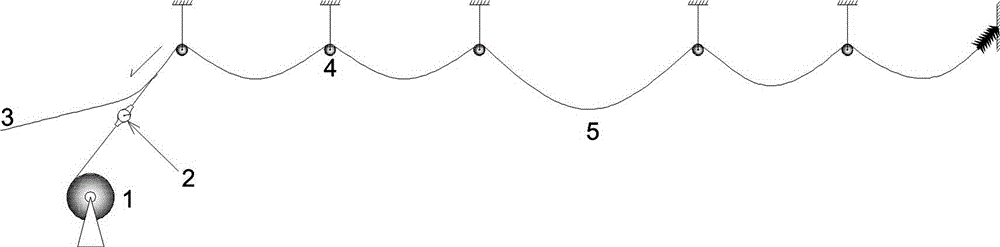

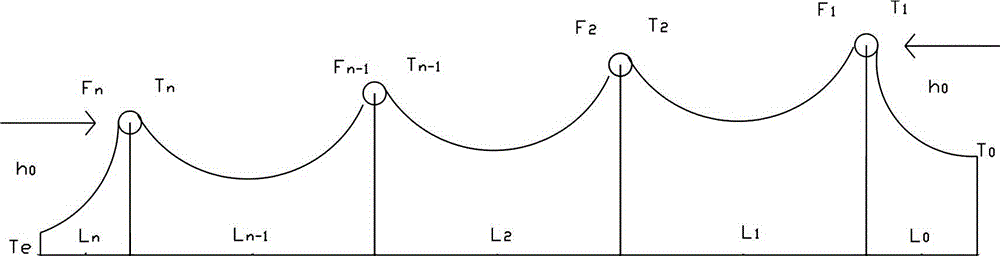

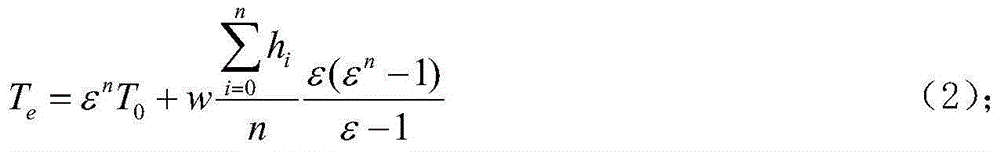

The invention relates to a sag observation method for power transmission line engineering construction. A mechanical model of sag control by a tension force in a tension state is established and applied forces on overhead lines of all towers are calculated based on formulas; and according to to-be-tightened-up zone, an observation grade is determined and a wire tightening-up field is arranged, a tension force value displayed by a tightening-up end tension measurement device corresponding to the designed sag by the observation grade is calculated, winching is started, the tension measurement device is observed; and the sag is controlled. According to the invention, from the perspective of the relation of the tension force, the stress, and the sag, the tension force is introduced into the overhead line tightening construction, so that the circuit stress control becomes simple and direct. Meanwhile, a problem that the sag can not be observed from the top or bottom of the overhead line tower at special areas like the high mountain areas can be solved.

Description

technical field [0001] The invention relates to a sag observation method for transmission line engineering construction, which relates to the field of transmission line monitoring. Background technique [0002] Traditionally, there are four commonly used methods for observing the conductance and ground sag of overhead transmission lines, generally including anomaly method, equal length method, angle method and head-up method. Generally, the equal-length method or the abnormal method is preferred. When the equal-length method or abnormal method cannot be used due to objective conditions, the angle method can be used. Only when the above three methods cannot be used, the head-up method is used. Before observing the sag, you should refer to the horizontal section diagram of the line to understand the terrain and sag conditions, select the appropriate sag observation method based on the actual situation, and calculate the initial elongation according to the line pole tower pos...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02G1/02

Inventor 苏攀

Owner CHINA THREE GORGES UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com