Efficient breakage-proof material storage bin

A storage bin and high-efficiency technology, which is applied in the field of storage bins for fruit materials, can solve the problems of poor anti-breaking effect, low space utilization rate, and high-quality finished products, so as to achieve convenient processing, reduce broken rate, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

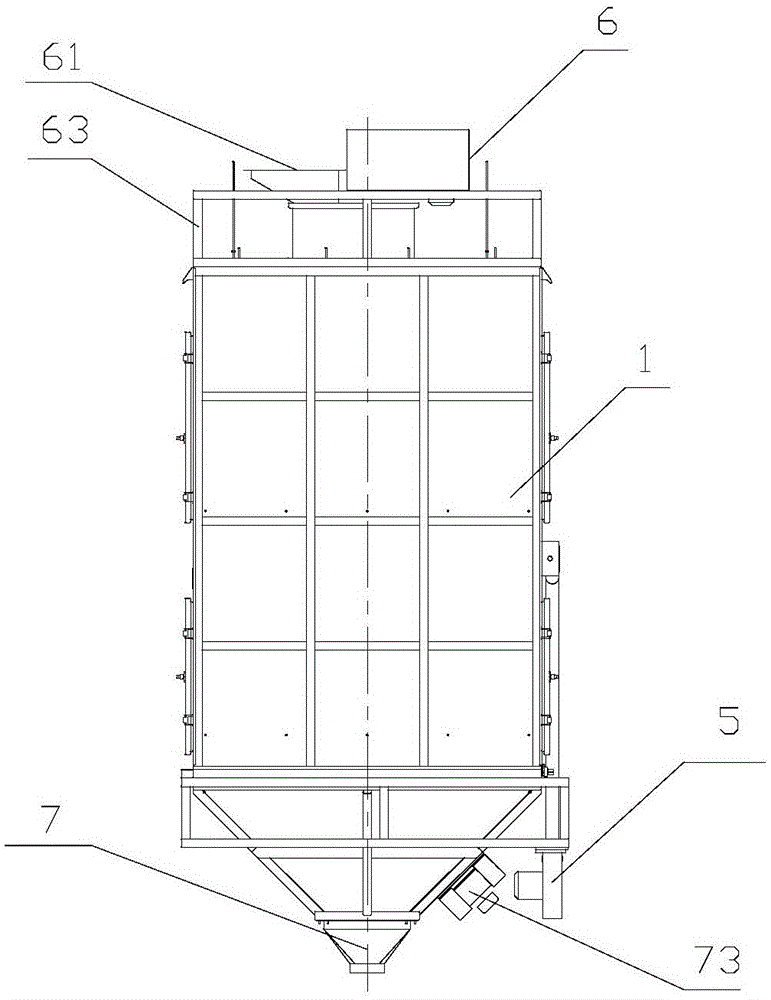

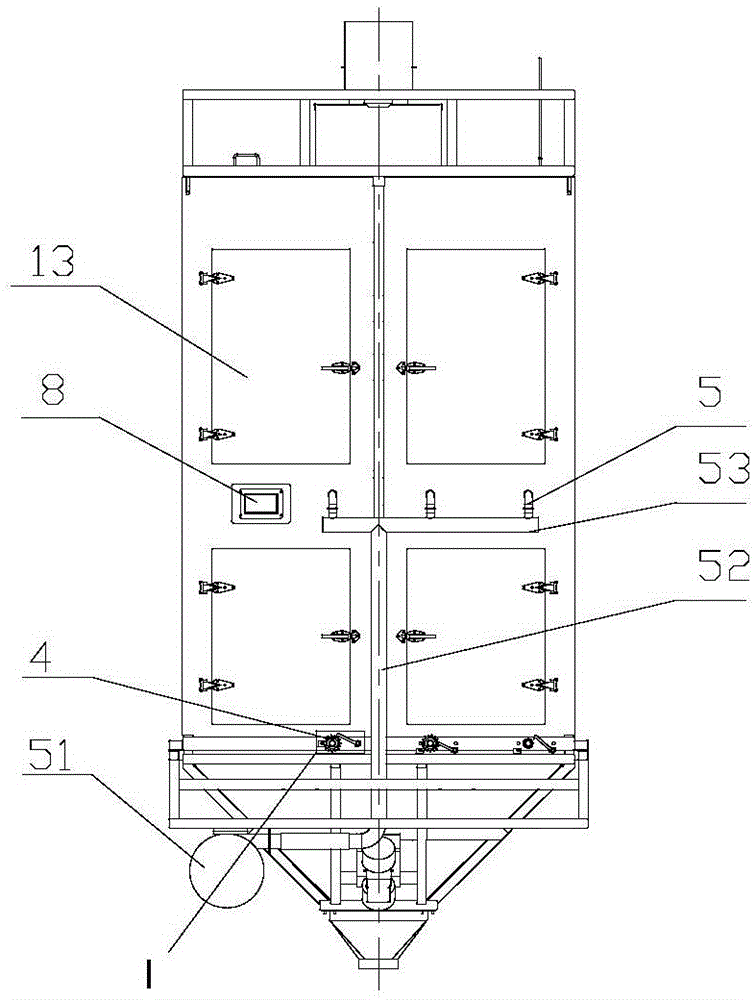

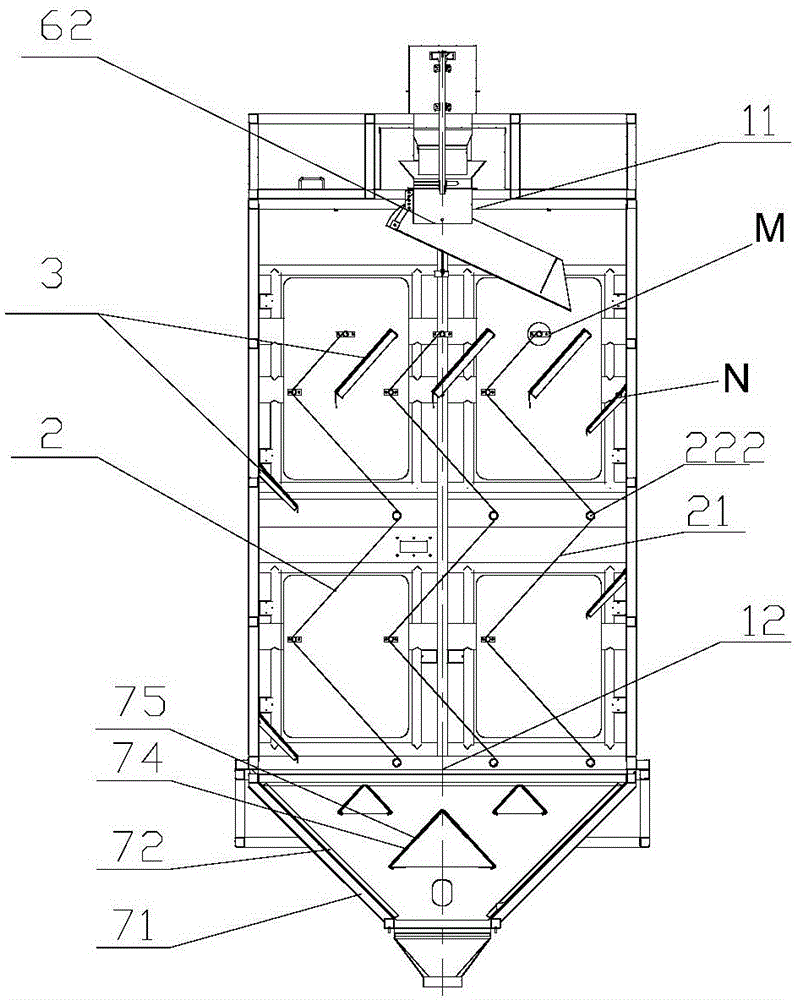

[0042] The present invention as Figure 1-8 As shown, it includes a feed part 6, a silo part and a discharge part 7 from top to bottom; the silo part includes a silo body 1 and several buffer mesh belt assemblies 2, and the top surface of the silo body 1 has an inlet 11. There is an outlet 12 on the bottom surface, and several buffer mesh belt assemblies 2 are arranged in the warehouse body 1;

[0043] The buffer mesh belt assembly 2 includes a mesh belt body 21 and a number of supporting round pipes 22, and several of the supporting round pipes 22 are connected in the warehouse body 1 in an S shape, so that the mesh belt body 21 is wound in an S shape. On several supporting round pipes 22.

[0044] The two ends of the mesh belt body are fixedly connected to the uppermost and lowermost support tubes, and the middle part is hung on the other support tubes. The support tubes connected to the same mesh belt body are arranged staggered up and down inside the warehouse body, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com