A mechanical device for automatically dusting oil barrels

The technology of a mechanical device and an oil drum is applied in the field of automatic ash-brushing mechanical devices for oil drums, which can solve the problems of unclean dust removal, high labor cost, low work efficiency, etc., and achieve the effect of saving labor and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

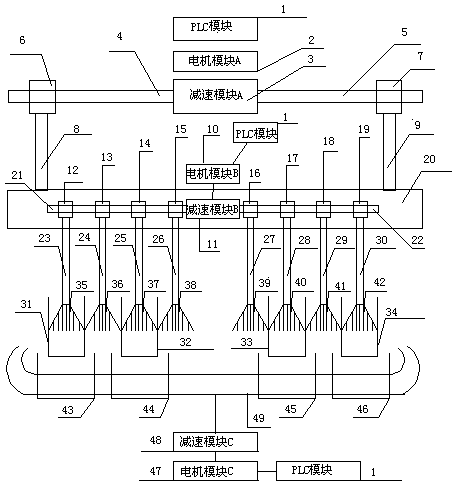

[0015] Such as figure 1As shown in the figure, a mechanical device for automatically dusting the oil tank includes PLC module 1, motor module A 2, deceleration module A 3, transmission shaft A 4, transmission shaft B 5, tape winding device A 6, tape winding device B 7 , lifting belt A 8, lifting belt B 9, motor module B 10, deceleration module B 11, bearing module A 12, bearing module B 13, bearing module C 14, bearing module D 15, bearing module E 16, bearing module F 17 , Bearing module G 18, Bearing module H 19, Mechanical arm 20, Drive shaft C 21, Drive shaft D22, Brush handle A 23, Brush handle B 24, Brush handle C 25, Brush handle D 26, Brush handle E 27, Brush Rod F 28, brush rod G 29, brush rod H 30, oil barrel A 31, oil barrel B 32, oil barrel C 33, oil barrel D 34, brush A 35, brush B 36, brush C 37, hair Brush D 38, brush E39, brush F 40, brush G 41, brush H 42, oil drum seat A 43, oil drum seat B 44, oil drum seat C 45, oil drum seat D 46 , motor module C 47, dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com