A fully automatic grinding device for castings

A casting and fully automatic technology, which is applied in the direction of grinding drive device, device for fixing grinding wheel, grinding/polishing safety device, etc. It can solve the problems of easily damaged equipment, roughness, and parts that cannot be polished, so as to save manpower and material resources, Long service life and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

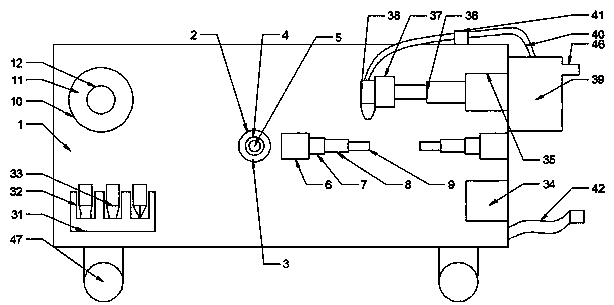

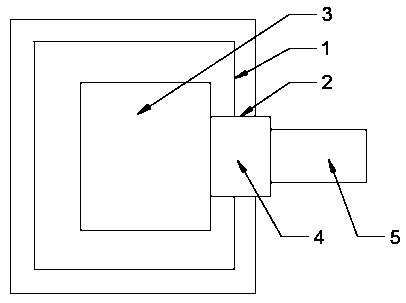

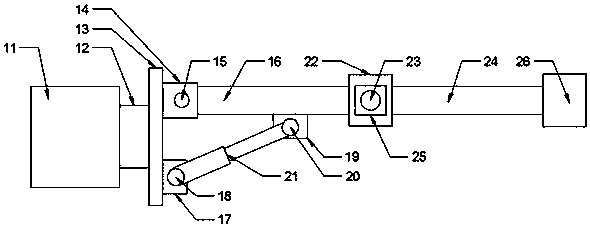

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a fully automatic grinding device for castings includes a grinding box body 1, the grinding box body 1 is placed on the ground, and a casting fixing mechanism is provided on the grinding box body 1, and the casting The fixing mechanism consists of a through hole-2 fixed on one side of the grinding box body 1, a small rotating motor-3 fixedly installed in the grinding box body 1 and the rotating end protruding from the through hole-2, and a small rotating motor-3 fixedly installed Coupling 1 at the rotating end 4, fixedly installed on the fixed shaft 5 on one side of the coupling 4, fixedly installing the side of the grinding box body 1 and the small rotating motor 2 corresponding to the rotating end on the side of the through hole 2 6, fixing The coupling two 7 installed on the rotating end of the small rotating motor two 6, the fixed bearing 8 fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com