Head boring machine used for machining steel pipes

A head cutting machine and steel pipe technology, which is applied in the field of steel pipe processing, can solve the problems of small application range and high production cost, and achieve the effects of increasing application range, improving work efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

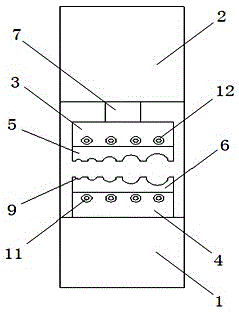

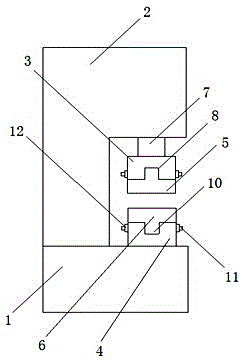

[0011] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0012] as attached figure 1 with 2 Shown:

[0013] A head cutting machine for processing steel pipes, comprising a base 1, a main machine 2, an upper mounting block 3, a lower mounting block 4, an upper pressing block 5 and a lower pad 6, wherein the main machine 2 is set on the base 1, the upper mounting block 3 is set on the main machine 2 through the lifting rod 7, and the mounting groove 8 is arranged on the upper mounting block 3, and the lifting rod 7 is used to facilitate the rising or falling of the upper mounting block 3, thereby realizing the For the cutting operation of the steel pipe, the lower mounting block 4 is arranged on the base 1, and the mounting groove 8 is arranged on the lower mounting block 4, and the punching hole 9 and the clamping block 10 are arranged on the upper pressing block 5, and The clamping block 10 is fixed in the installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com