A Forming Method for Nano/Ultrafine Crystal Cylindrical Parts Prepared by Small Strain

A technology of ultra-fine grain and cylindrical parts, which is applied in the field of plastic forming of metal materials, can solve the problems of difficult control of forming quality, small volume of bulk materials, large deformation, etc., and achieves favorable control of forming quality and mechanical properties Uniform, good plastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

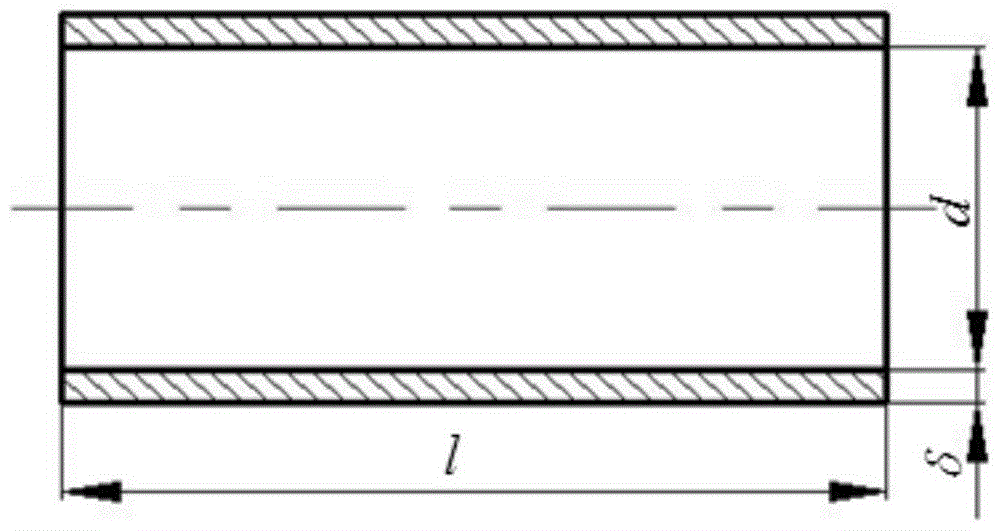

[0038] Seamless cylindrical blank, the material is 10 steel (0.1% carbon content), the shape is as figure 1 Shown, its inner diameter d=182mm, wall thickness δ=2.4mm, length l=500mm. In addition to size requirements, it is also necessary to obtain an ultra-fine grain structure with an average grain size of less than 1 μm.

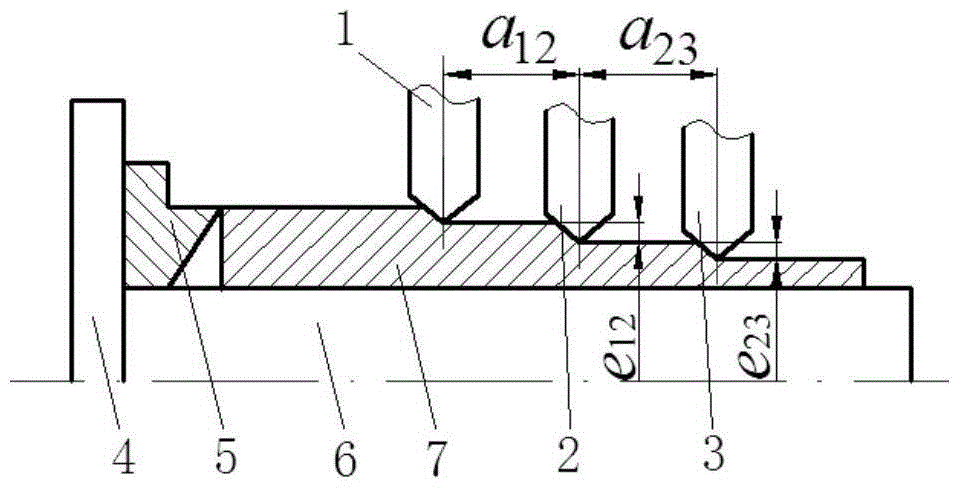

[0039] 1. Use 10-steel seamless steel pipe with a specification of φ194*6mm available on the market as the blank, with an inner diameter of 182mm and a wall thickness of 6mm (such as Figure 4 As shown), the wall thickness of the parts required for forming pipes of this specification is reduced from 6mm to 2.4mm, and the thinning rate is 60%. Therefore, the tube blank is used for multi-pass staggered spinning after quenching, and finally recrystallization annealing. The microstructure and Figure 7 Closely, the average grain size is 40 μm.

[0040] Lengthen the blank by 15mm as the fixed part of the bottom, take 10mm as the trimming allowance at the mou...

Embodiment 2

[0047] Seamless cylindrical blank, the material is 20 steel (0.2% carbon content), the shape is as figure 1 Shown, its inner diameter d=68mm, wall thickness δ=1.8mm, length l=200mm. In addition to size requirements, it is also necessary to obtain an ultra-fine grain structure with an average grain size of less than 1 μm.

[0048] 1. The 20-steel seamless steel pipe with a specification of φ76*4mm that can be purchased on the market is used as the blank, with an inner diameter of 68mm and a wall thickness of 4mm (such as Figure 4 Shown), using the parts required for blank forming of this specification, the wall thickness is reduced from 4mm to 1.8mm, and the thinning rate is 55%. Therefore, the part is to be prepared by quenching, staggered spinning, and recrystallization annealing (such as Figure 6 shown). The microstructure of this steel pipe blank is as follows Figure 7 As shown, the average grain size is about 50 μm.

[0049] Lengthen the blank by 15mm as the fixed ...

Embodiment 3

[0055] Seamless cylindrical blank, the material is 20 steel (0.2% carbon content), the shape is as figure 1 Shown, its inner diameter d=100mm, wall thickness δ=1mm, length l=200mm. In addition to size requirements, it is also necessary to obtain an ultra-fine grain structure with an average grain size of less than 1 μm.

[0056] 1. The wall thickness of the seamless steel pipe with an inner diameter of 100mm that can be purchased on the market is at least 4mm. Since the thinning rate cannot exceed 60% during strong spinning of the blank, otherwise cracks will occur, and the nano / Ultra-fine crystal cylindrical parts have good plasticity and can be used for subsequent spinning forming. Therefore, tube blanks with a specification of φ108*4mm are used. After quenching, staggered spinning is performed, and the wall thickness is reduced from 4mm to 2mm (reduced Thinness rate 50%), followed by recrystallization annealing, its plasticity recovery, and then staggered spinning, its wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| recrystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com