Airborne powder sending roller laser cladding preheating tool

A technology of laser cladding and powder feeding, which is applied in metal material coating process, coating, etc., can solve the problems of waste cost of powder recovery device and low powder utilization rate, and achieve improved controllability, convenient installation and improved molding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

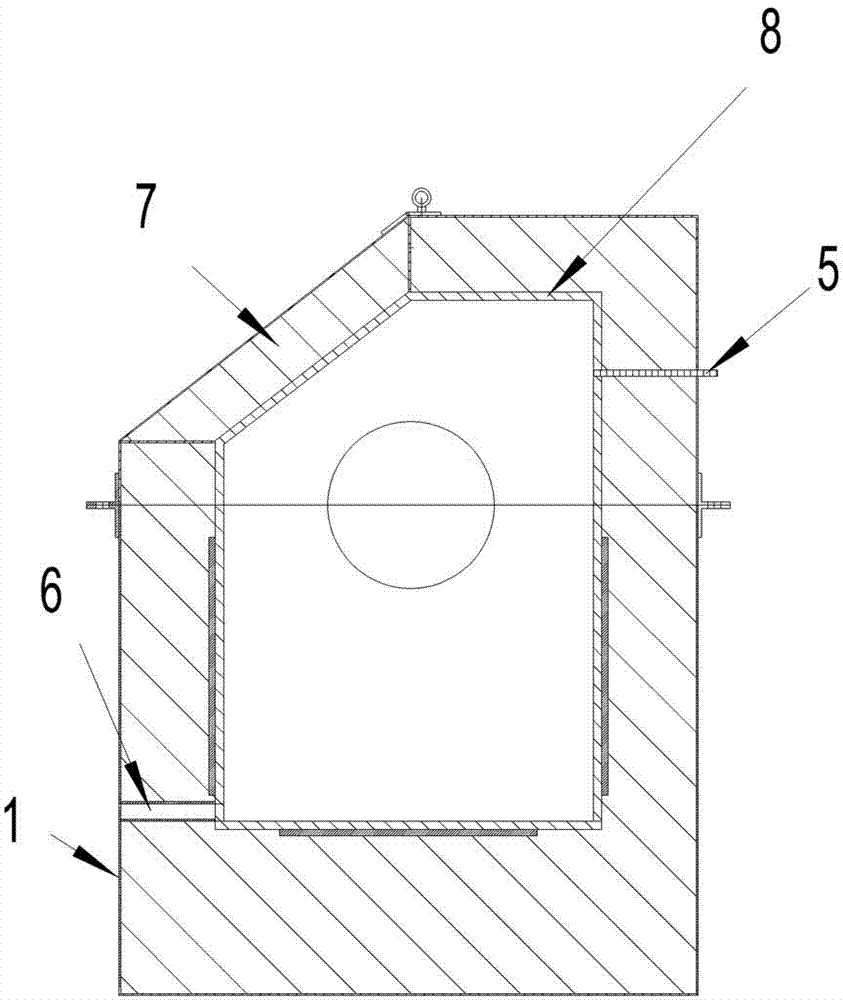

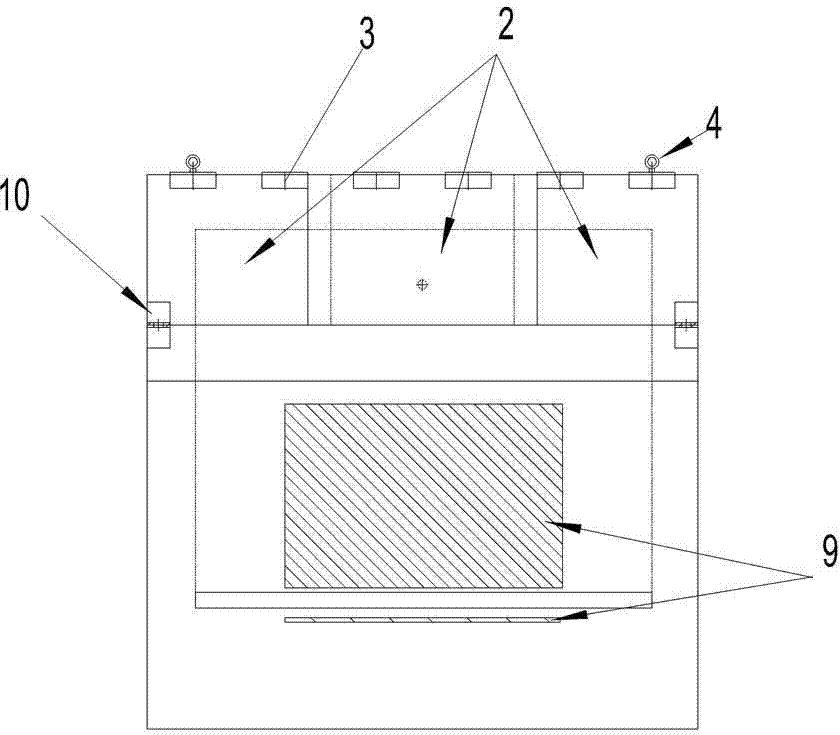

[0020] Such as Figure 1 ~ Figure 2 As mentioned above, this kind of laser cladding preheating tooling for air-borne powder feeding rolls includes a furnace body 1 welded by angle steel and a furnace made of stainless steel plates, wherein the furnace body 1 of the tooling is a lateral opening structure divided into upper and lower parts , that is, the upper opening structure of the original furnace body 1 is changed from the left and right halved upper end opening structure to the upper and lower halved side opening structure. The main thing is that the airflow at the side opening of the furnace body 1 is relatively gentle, and the angle between the powder nozzle and the updraft is larger when laser cladding is performed here, and the influence of the updraft on the powder feeding airflow is significantly reduced, and the cladding layer Surface forming quality is well controlled. Moreover, laser processing in the lateral direction is convenient for the operator to operate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com