Roundness-bending forming device

A forming device and round-bending technology, which is applied in the field of mechanical processing, can solve problems such as irregular bending of solder rings, difficulty in meeting technical requirements, and prone to scratches on the surface, so as to reduce surface damage, smooth surface, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and examples.

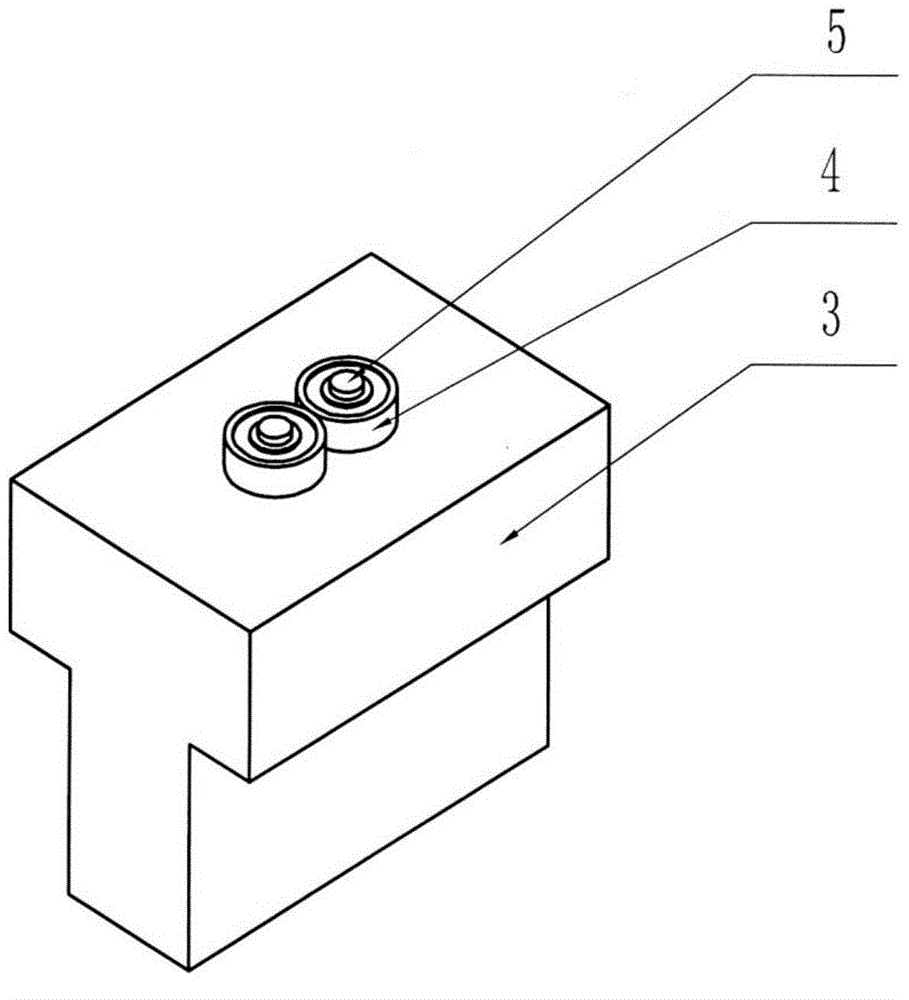

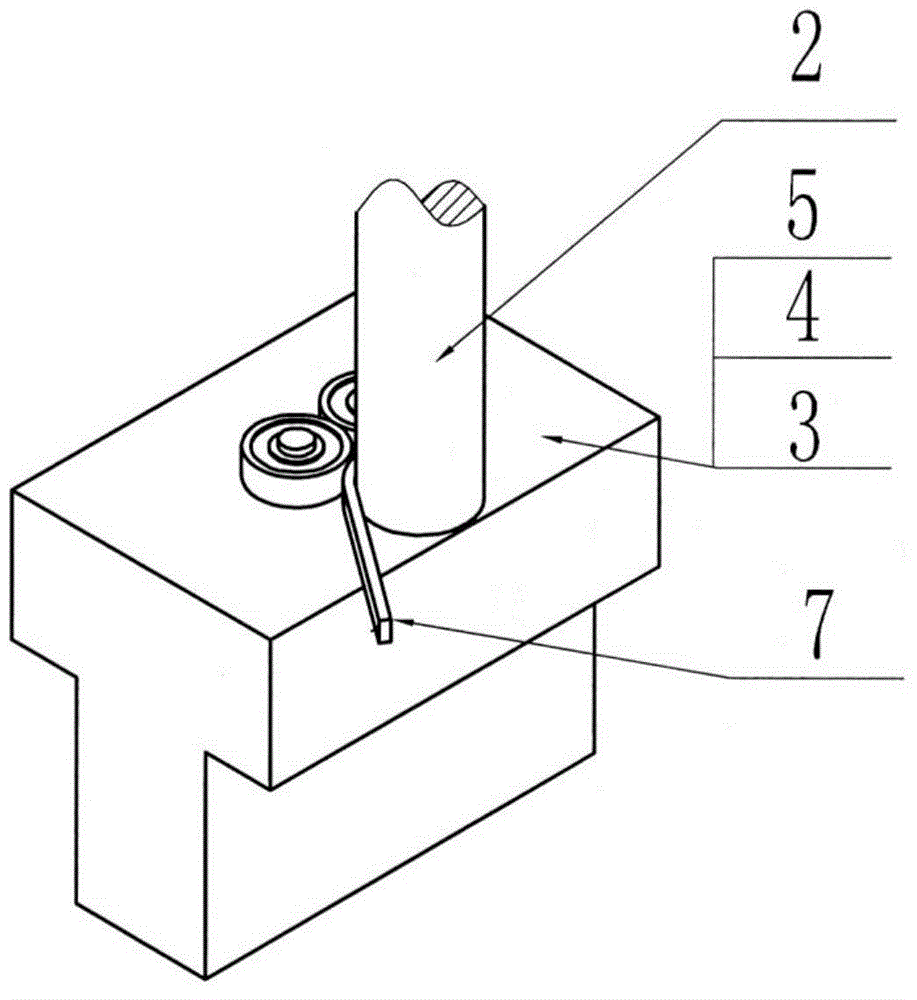

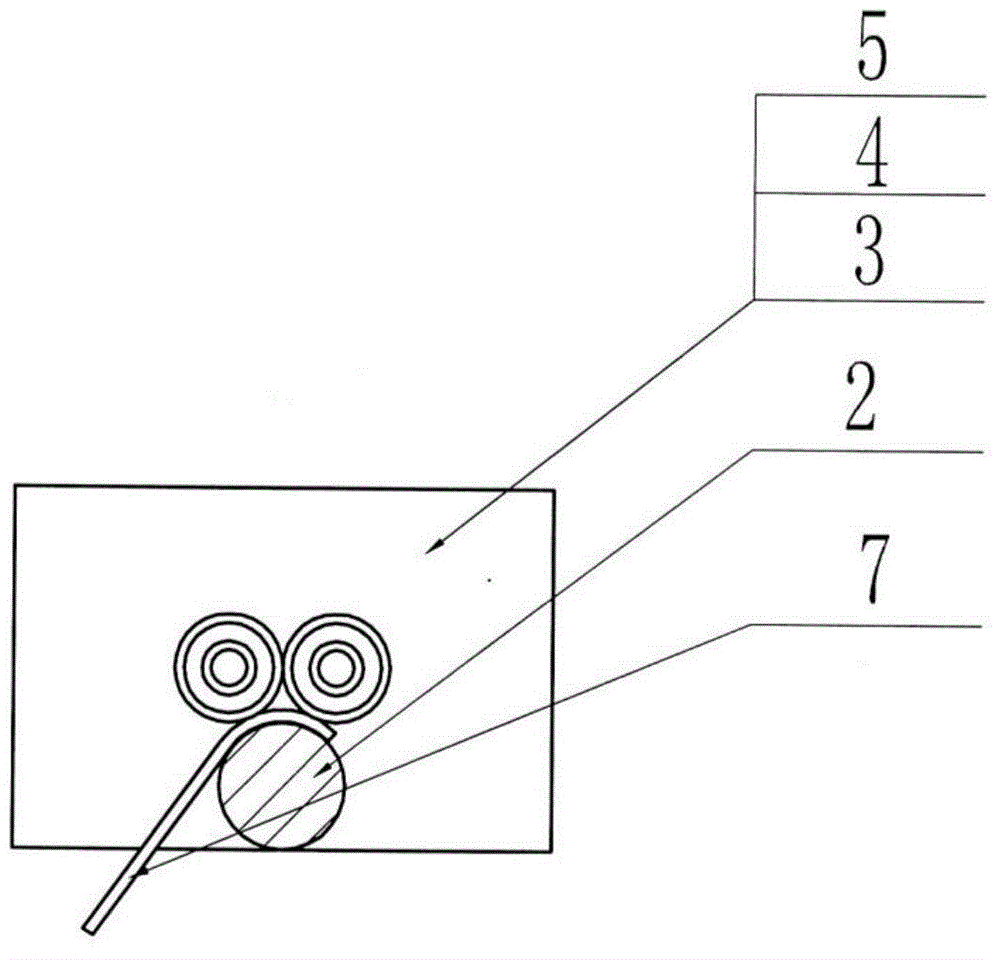

[0016] A bending and forming device, which includes a support 3, two positioning pins 5, two bearings 4, a mandrel 2 and a mandrel drive mechanism, wherein two positioning pins 5 are fixed on the support 3, and two The bearings have the same size, and are respectively fixed on the positioning pin 5 through the inner ring of the bearing. The outer circumferential surfaces of the two bearing outer rings are adjacent and do not touch (to ensure no friction, the distance is 0.01 ~ 0.1mm); one end of the mandrel 2 is fixed Connected to the drive mechanism of the mandrel, a horizontal gap is formed between the other end and the surface of the support 3, and the axis of the mandrel 2 is located on the perpendicular line of the line connecting the centers of the two bearings, and the outer circumference of the mandrel is in line with the outer surface of the bearin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com