Bracket

A technology of brackets and brackets, which is applied in the field of brackets, can solve problems that affect deep processing and affect the quality of semi-finished products, and achieve the effects of large load-bearing capacity, convenient placement and picking of workpieces, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

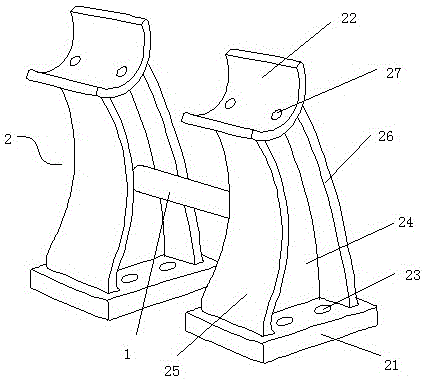

[0016] Such as figure 1 As shown, a bracket includes a cross bar 1 and support devices 2 connected by the cross bar 1 and symmetrically arranged at both ends of the cross bar 1. Therefore, the bracket is actually a symmetrical structure. As the stress point of the workpiece, there is sufficient guarantee for the safety of the workpiece after it is placed. It is preferable that the crossbar 1 is a cylinder. In addition to being smooth and without edges and corners, it will not hurt the workpiece or the worker, and its round shape is also beneficial to the hand of the worker. It is very convenient to carry and take the bracket.

[0017] Specifically, the supporting device 2 includes a base 21 for stabilizing the supporting device 2, an arc-shaped holder 22 for supporting the workpiece, and a support part connecting the base 21 and the arc-shaped holder 22, wherein the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com