U-type sail structure

A sail and U-shaped technology, which is applied in the field of U-shaped sail structure, can solve the problems of reducing the reliability of the sail system, complicated flap control methods, and increasing the complexity of the sail system, and achieves a wide range of effective wind directions for boosting, a simple structure, The effect of neat appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

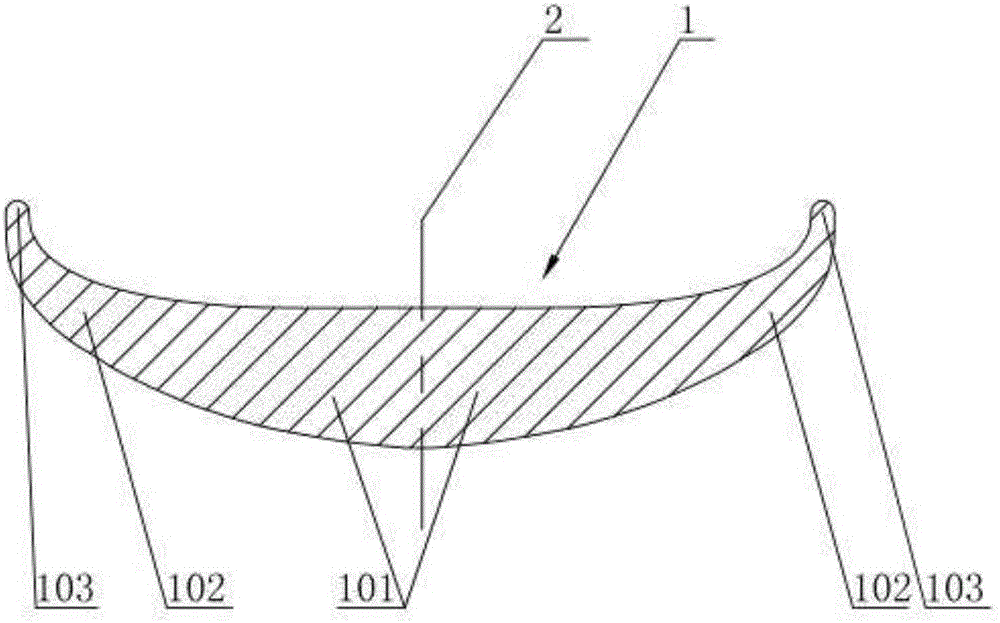

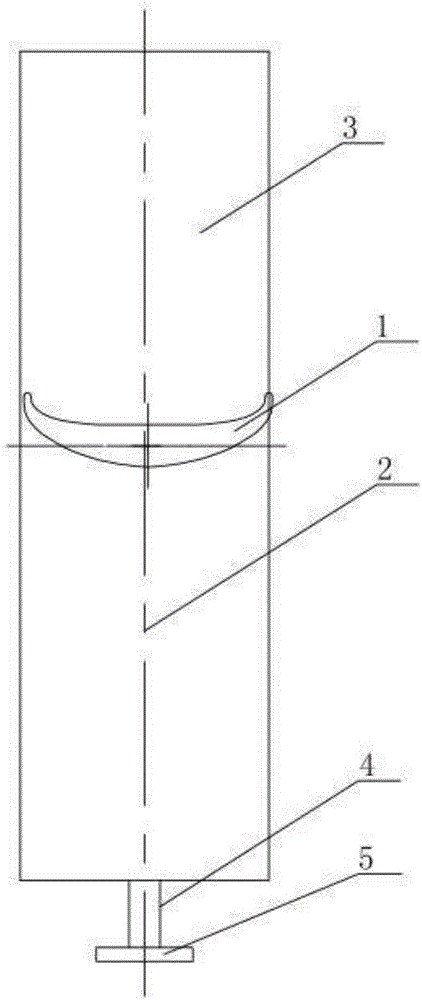

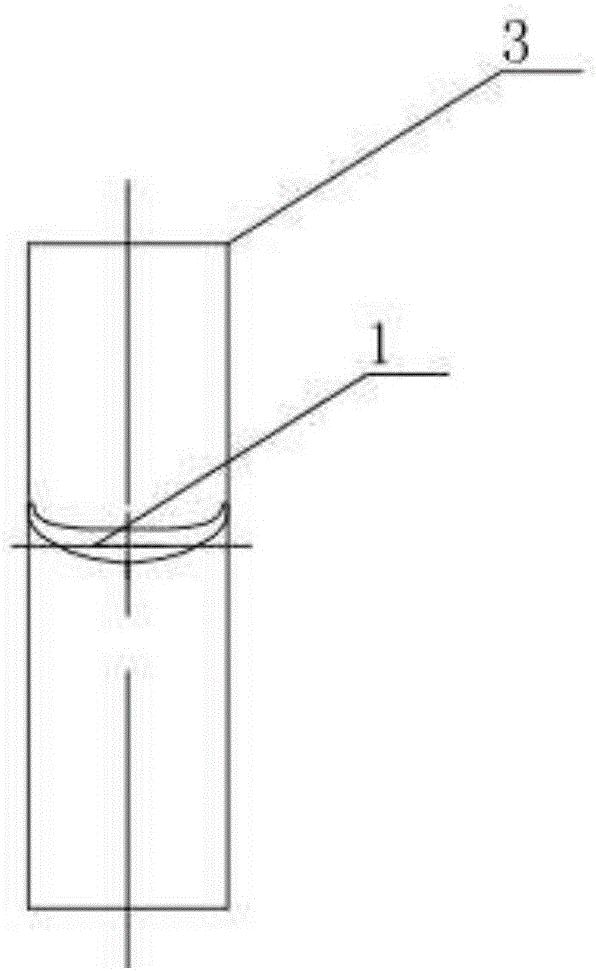

[0026] Such as figure 2 As shown, the U-shaped sail structure includes the sail body 3, the sail body 3 is connected to the sail base 5 through the sail mast 4, the cross section of the sail body 3 forms a section structure 1, and the section structure 1 adopts a front-rear symmetrical aerodynamic shape, as shown in figure 1 As shown, the cross-sectional structure 1 is integrally connected by a pair of main body parts 101, a pair of arched parts 102 and a pair of round guide parts 103 to form a "U"-shaped structure. Arranged symmetrically around the center of the sail rotation axis 3, such as figure 1 As shown, the thickness of the main body 101 shows a decreasing trend along the arched portion 102, and the above-mentioned rounded portion 103 is located at the outermost side of the “U”-shaped structure, and the rounded portion 103 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com