Pulley-chute connection structure applied to anti-drop door window

A connection structure and anti-falling technology, which is applied in door/window fittings, building structures, and wing leaf suspension devices, etc., can solve the problems of door and window glass shattering, inconvenient use, and window sash deformation, and achieve smooth sliding and convenient use , the effect of force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

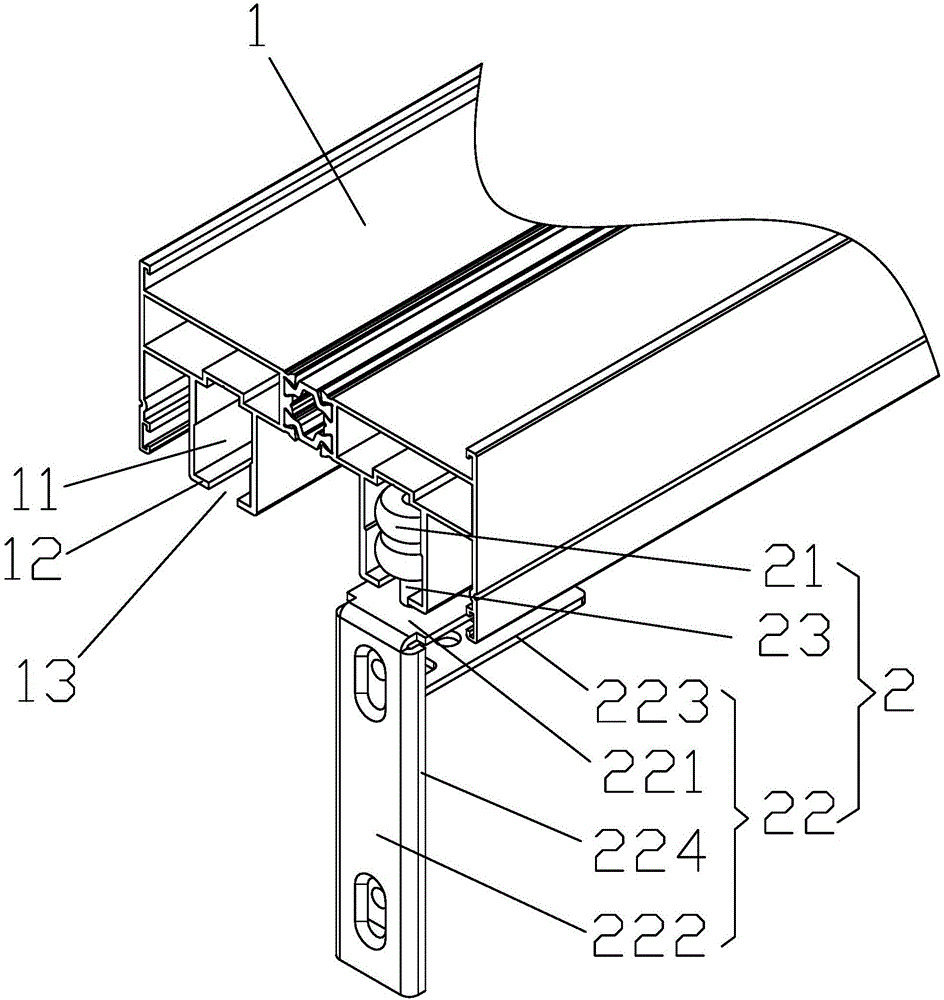

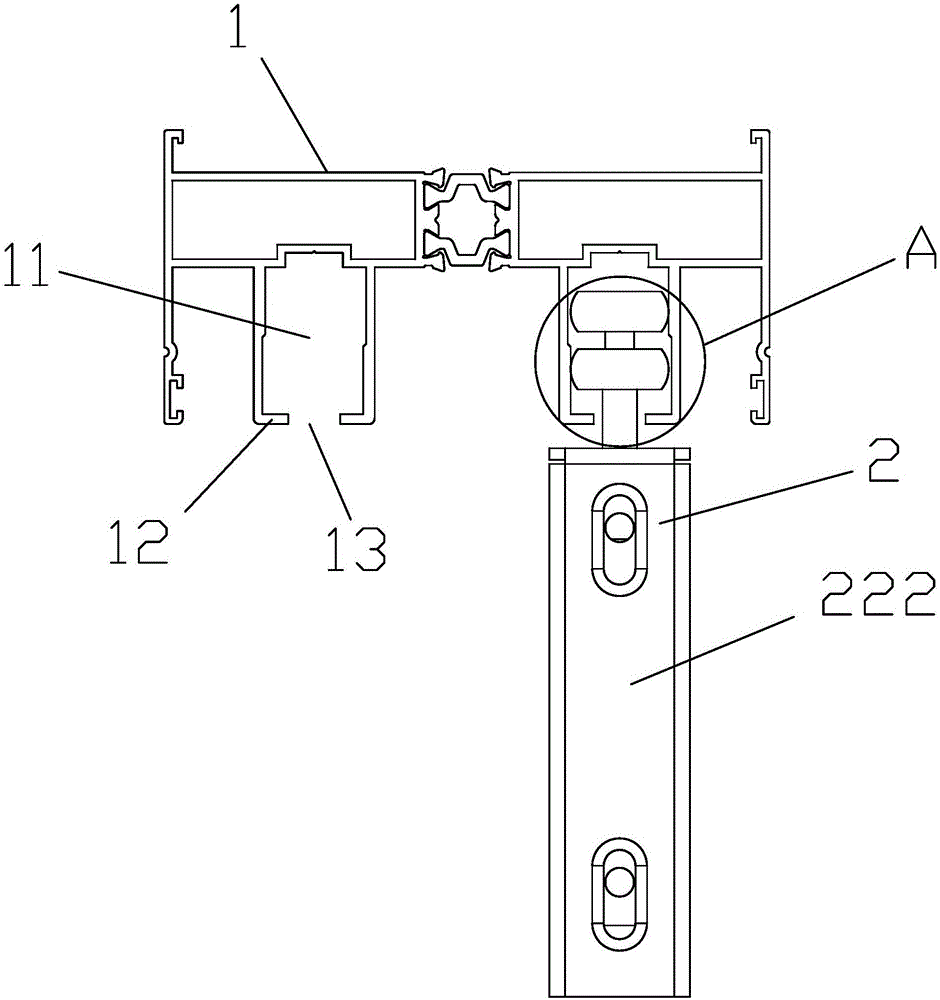

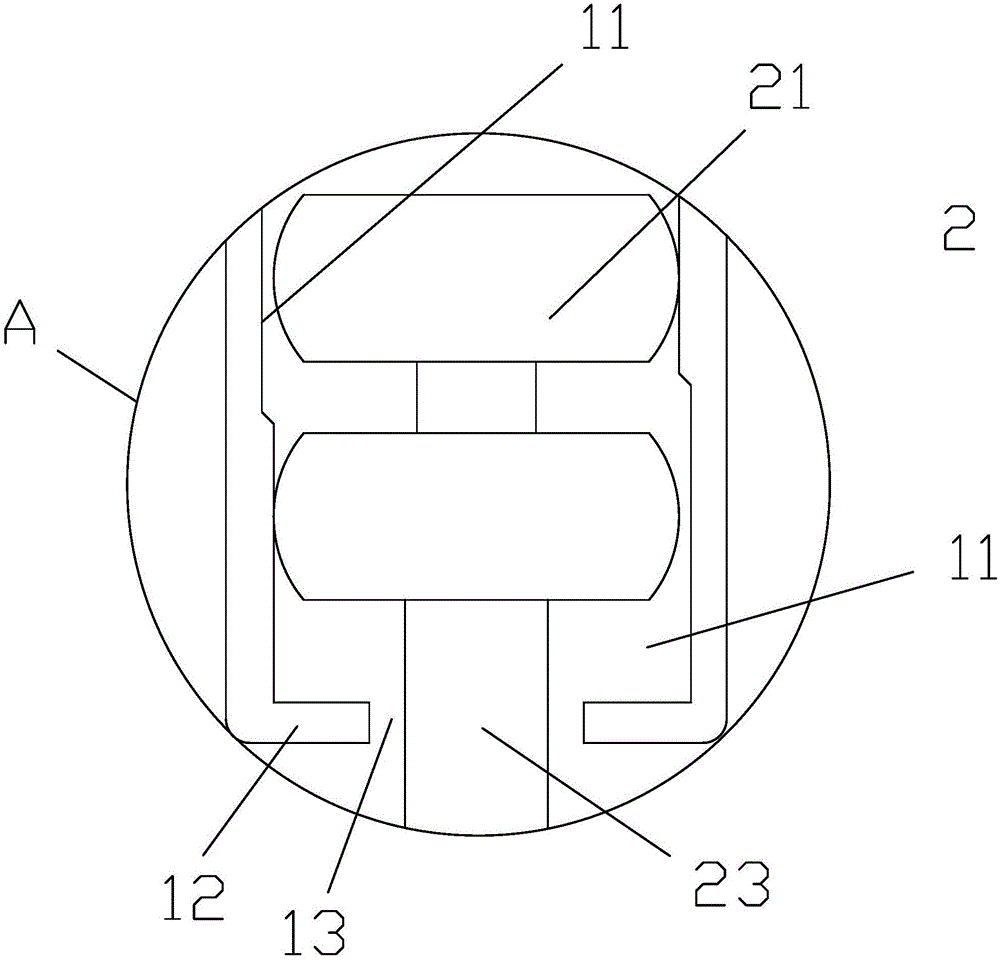

[0017] refer to Figure 1 to Figure 3 A pulley and chute connection structure applied to anti-falling doors and windows provided by the present invention includes a window frame 1, a window sash installed in the window frame 1, a pulley block 2 is arranged on the upper end of the window frame, and the window frame 1 The inner side of the upper beam is provided with a chute 11 corresponding to the pulley block 2, and the pulley 21 of the pulley block 2 is attached to the inner wall of the chute 11 to slide. The pulley block 2 includes a base 22 connected with the window sash, an upwardly extending installation shaft 23, Two pulleys 21 installed on the installation shaft 23, two pulleys 21 are arranged from top to bottom, and described chute 11 comprises two slideways that are arranged from top to bottom, and the width of described slideway is greater than the diameter of pulley 21, wherein The left inner wall of the slideway below is close to the left side of the pulley 21 belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com