Calibration method for helicopter fuel oil indication system

A calibration method and helicopter technology, applied in the field of aviation instruments, can solve the problems that software control and pipeline design cannot meet the technical requirements of new products, fluid flow, quality and other parameters cannot be displayed in a centralized manner, and the control method is outdated, etc., to achieve optimal software design , increase the pressure parameter display, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

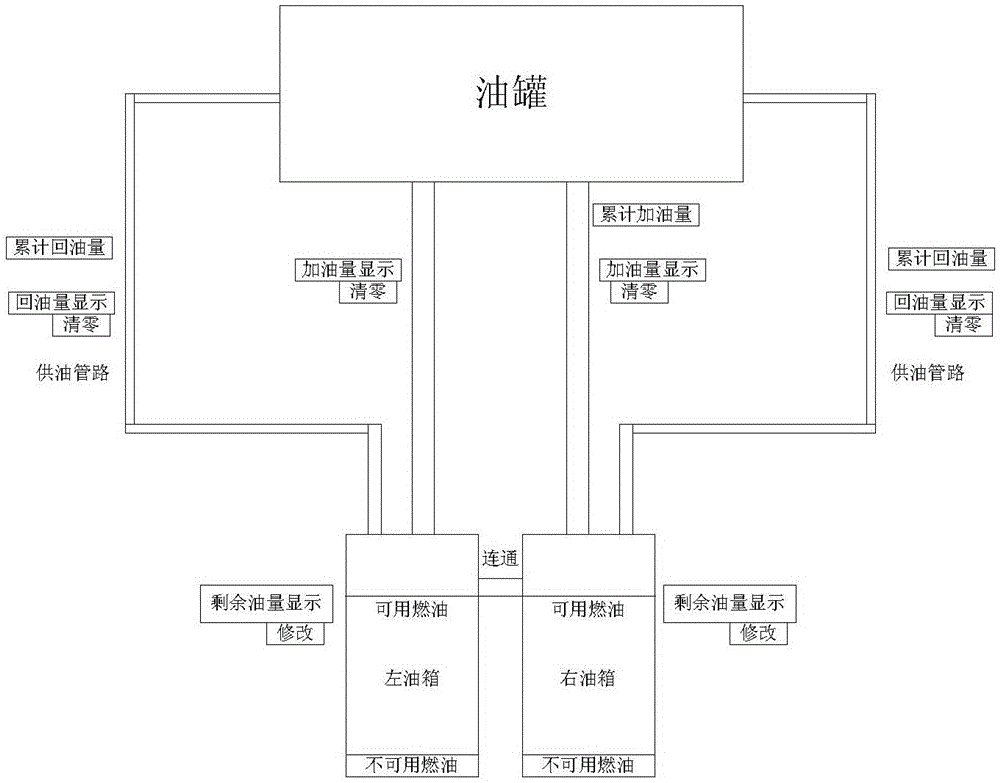

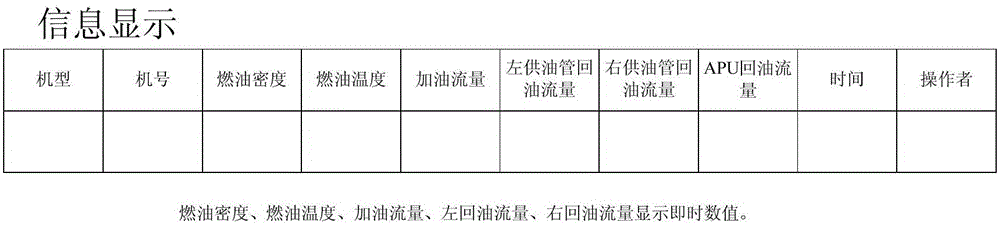

[0027] Helicopter Fuel Indicating System Calibration Process

[0028] 1) Connect the oil return line of the tester to the oil supply line of the helicopter engine to simulate the oil supply from the helicopter to the engine so as to calculate the return oil quality, pressure and flow parameters.

[0029] 2) Turn on the power of the tester, turn on the switches of each pipeline, operate the tester to add an appropriate amount of fuel to the helicopter, and the tester will automatically record the quality A of the added fuel.

[0030] 3) Turn on the fuel booster pump of the helicopter, and return fuel to the tester until no more fuel can be pumped out, and the tester will automatically record the returned fuel quality B.

[0031] 4) The difference between the total amount of added fuel A and the total amount of returned fuel B is the amount of non-fuel remaining in the helicopter fuel tank C=A-B. ,

[0032] 5) At this time, adjust the helicopter fuel indication system to make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com