Online monitoring and fault diagnosing method for mixing and flavouring process of cigarette filament production based on principal component analysis

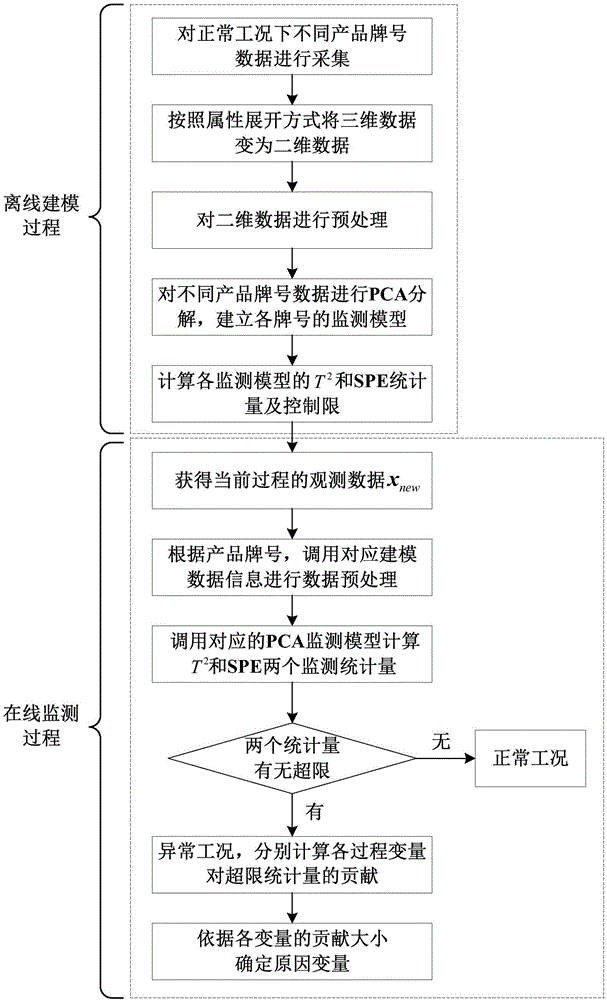

A technology of principal component analysis and fault diagnosis, which is applied in the online monitoring and fault diagnosis of flavoring machines and leaf silk blending machines, and can solve the problems of unequal data length, slow time change, and low accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

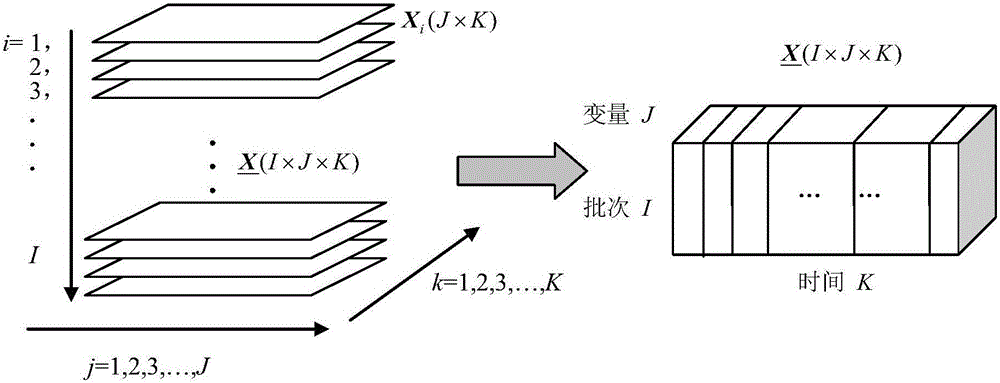

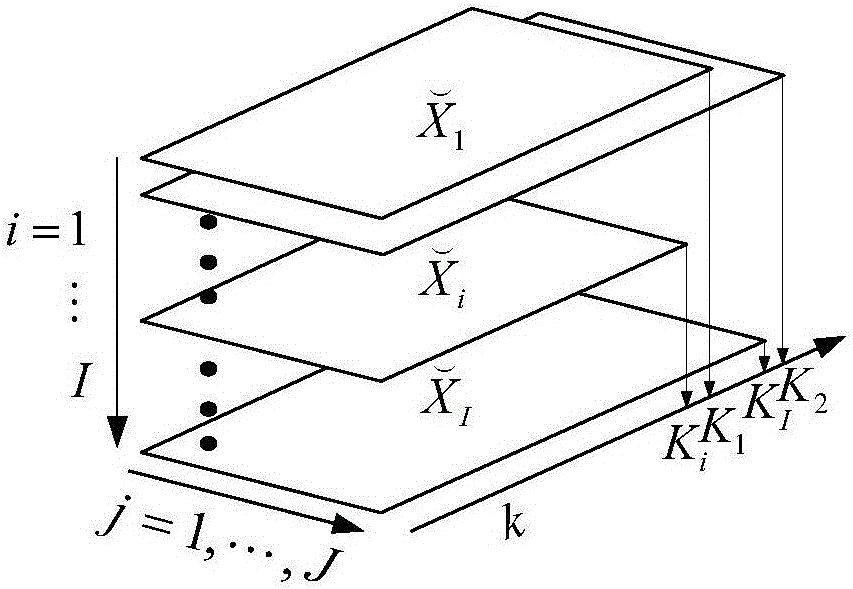

Method used

Image

Examples

Embodiment Construction

[0069] In order to better understand the technical solutions of the present invention, the implementation manners of the present invention will be further described below in conjunction with the accompanying drawings in the specification.

[0070] This implementation is an online monitoring and fault diagnosis method for the blending and flavoring section of the cigarette shred process, mainly for the shredded blending machine and KAS flavoring machine of Hauni Company in Germany. The main function of the shredded tobacco blending machine is to accurately and evenly blend shredded leaf, expanded shredded tobacco, expanded cut tobacco, thin shredded tobacco, recycled shredded tobacco, etc. according to the product formula design requirements to form a finished tobacco shredded formula group. The shredded leaf blending machine has 9 channels in total, which are shredded leaf A channel, leaf shredded channel B, leaf shredded channel C, expanded silk channel, stem shredded A channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com