A Specimen Fixer Automatic Control System for Microscope Stage

An automatic control system and specimen fixation technology, used in microscopes, instruments, optics, etc., can solve the problems of relying on manual adjustment and lack of flexibility, and achieve the effect of accurate movement control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

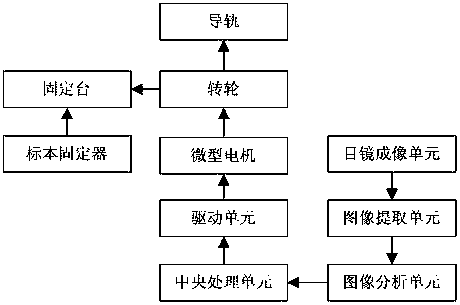

[0024] The automatic control system adopted in this embodiment includes: a transmission mechanism, a micro motor, a drive unit, a central processing unit, an eyepiece imaging unit, an image extraction unit, and an image analysis unit, wherein the eyepiece imaging unit is arranged on the eyepiece for placing the eyepiece The image is generated from the sample on the image; the image extraction unit is used to extract the generated image in real time; the image analysis unit is used to analyze the extracted image, judge the coverage area of the sample in the image to obtain a coverage value; The central processing unit is used to judge according to the coverage value, and generates a control signal when the coverage value is lower than the preset coverage value; the drive unit is used to convert the control signal into a drive signal output; the micro motor , for generating a driving force according to the driving signal, and the driving force drives the transmission mechanism ...

Embodiment 2

[0027] In this embodiment, different from the embodiment, the automatic control system includes: a transmission mechanism, a micro motor, a drive unit, a central processing unit, an eyepiece imaging unit, an image extraction unit, and an image analysis unit, wherein the eyepiece imaging unit is set On the eyepiece, it is used to generate an image of the specimen on the eyepiece; and, the transmission mechanism includes a guide rail, a runner and a fixed platform, and the guide rail is fixedly arranged on the surface of the stage; the center of the runner is fixedly connected to the guide One end of the rod, and the other end of the guide rod are fixedly connected with the rotating shaft of the micro motor; the fixed table is fixed on the rotating wheel through a bracket, and a specimen holder is arranged on the surface of the fixed table. The structure utilizes the way of rotating and moving in the guide rail to flexibly realize the movement, improve the flexibility and save th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com