Positioning device for cross rail in processing machine

A positioning device and processing equipment technology, applied in metal processing equipment, precision positioning equipment, metal processing machinery parts, etc., can solve the problems of increasing the diameter of the piston rod of the cylinder, the diameter of the cylinder cannot be too large, and the non-hydraulicization cannot be realized. Achieve rapid movement control, improve support strength, and improve positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

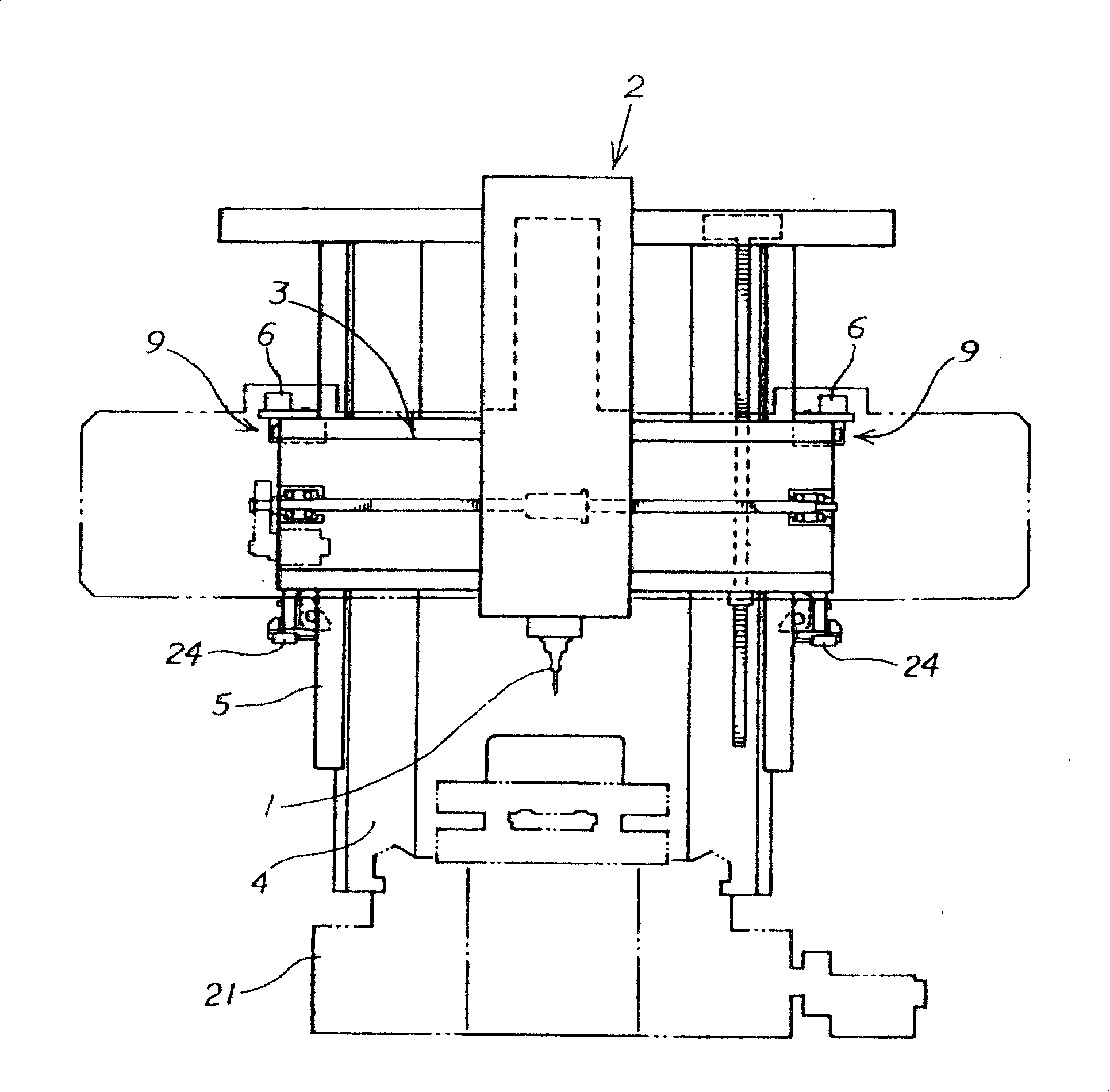

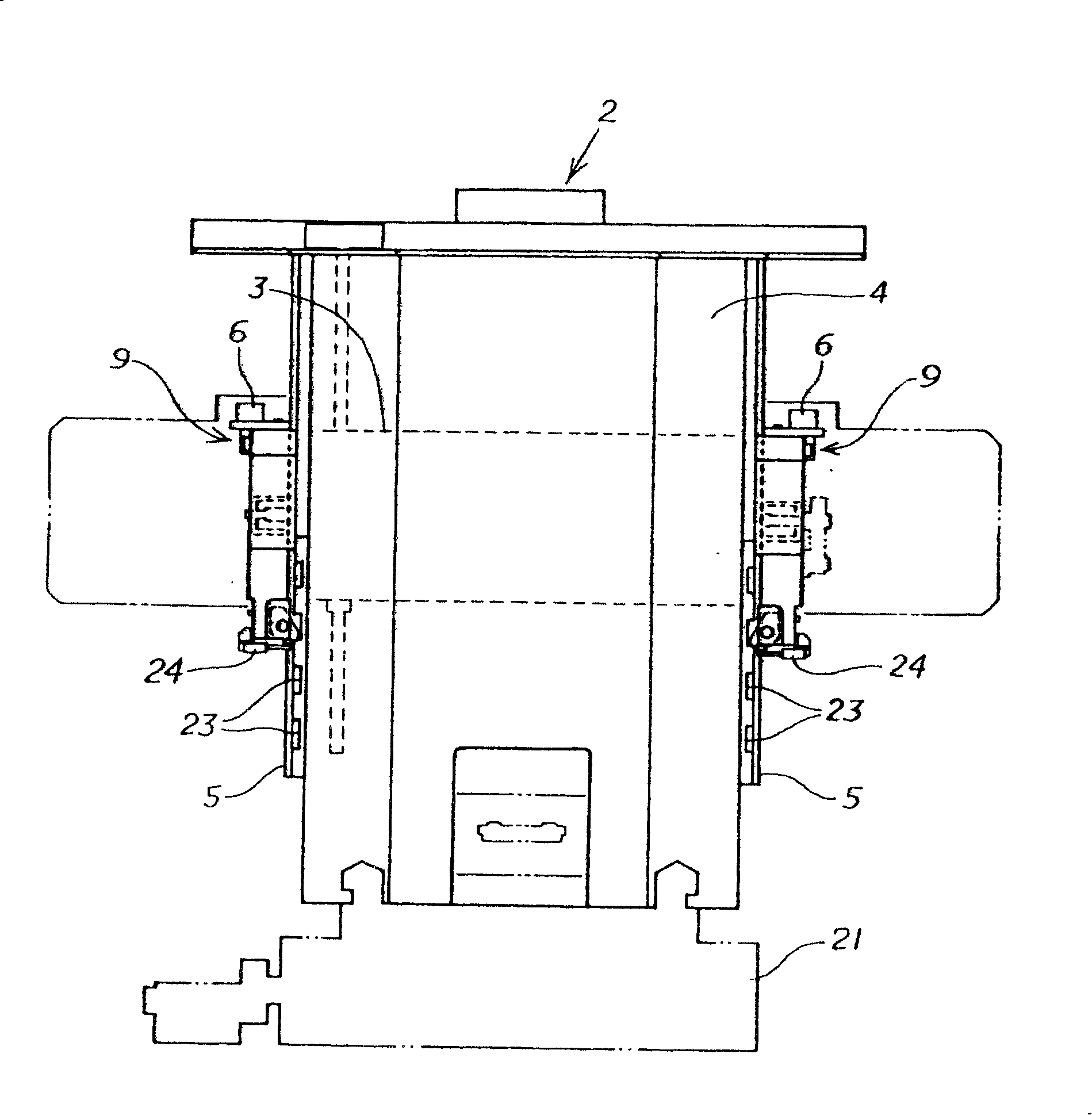

[0030] The following is a brief description of what is considered to be the best embodiment of the present invention (how to implement it) based on the accompanying drawings, and shows its function and effect.

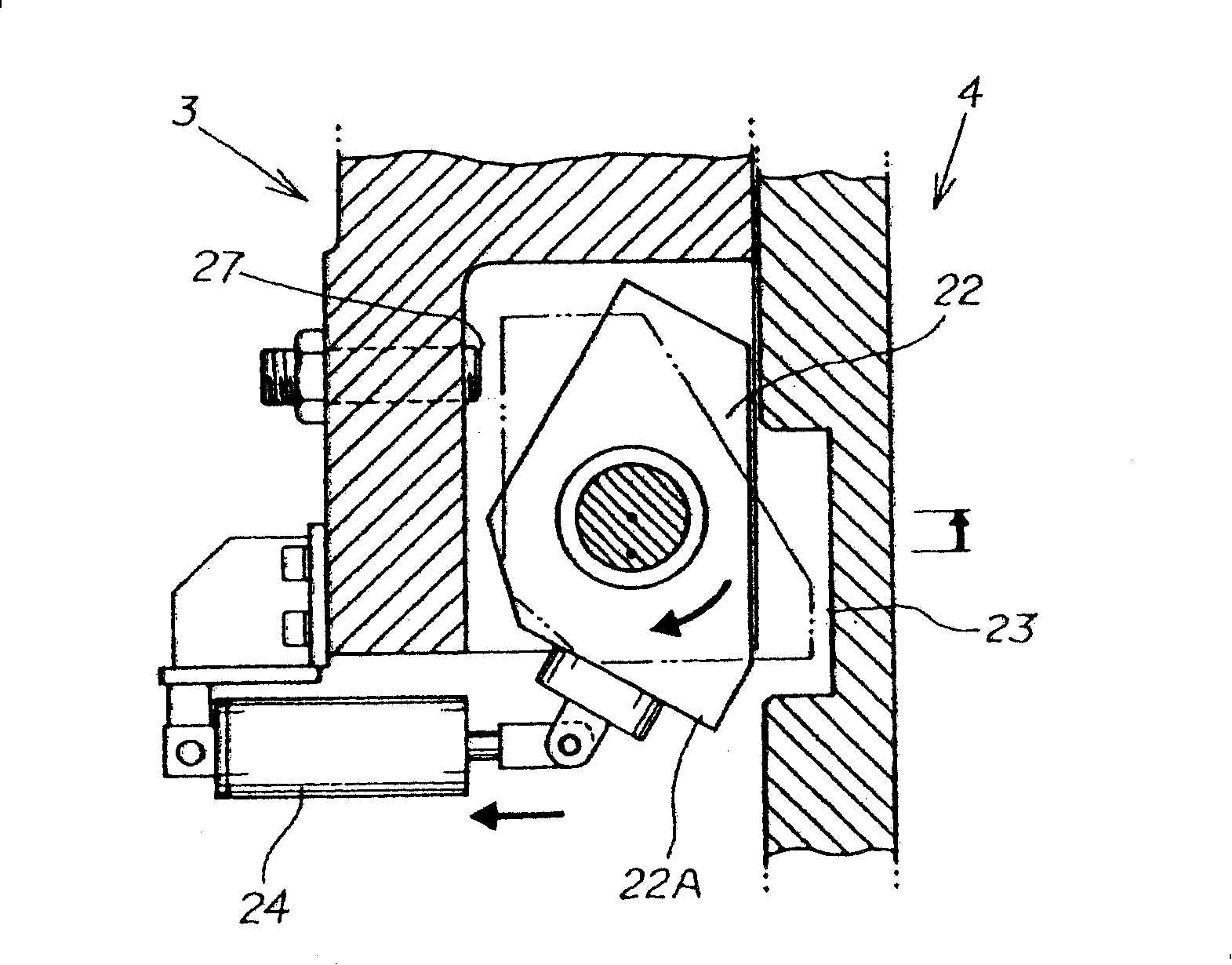

[0031] After the horizontal rail 3 is moved along the guide rail 5, when the above-mentioned rotation locking part 22 is rotated by the driving of the locking release driving device 24, or by the force released by the locking releasing driving device 24, relative to the set The rotation locking part 22 that is in a non-moving state through a plurality of engaging parts 23 is in a protruding state by this rotation, and the protruding part 22A of the rotation locking part 22 selectively engages with one of the plurality of engaging parts 23. The rail 3 is supported and held at a desired position through the engagement (locking).

[0032] In addition, for example, the guide rail 5 is pressed by a clamping device, the cross rail 3 is pulled close to the guide rail 5 and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com