Thread surface stretching device and thread surface production machine using the same

A stretching device and production machine technology, applied to dough forming machinery or equipment, application, dough processing, etc., can solve the problems of low stretching efficiency, achieve high stretching efficiency, reduce matching accuracy, and simple overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

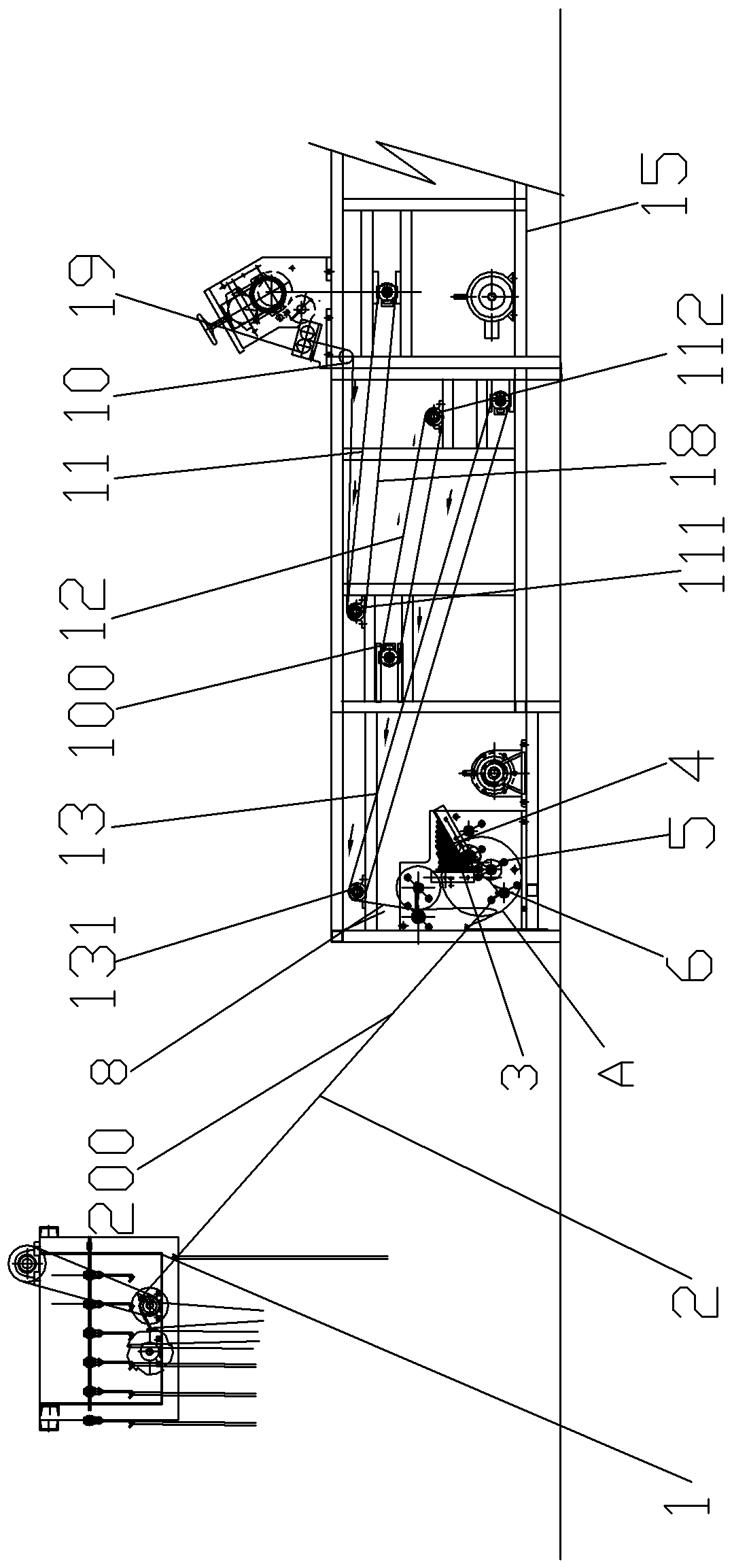

[0026] Such as figure 1 , figure 2Shown, a kind of embodiment of thread surface production machine, the thread surface production machine in this embodiment comprises the thread surface that is used for stretching the thread surface cut out by the thread surface cutting mechanism in the thread surface production machine Stretching device 100 and the noodle bar pick-up device 200 for accepting the stretched thread surface processed by the thread surface stretching device.

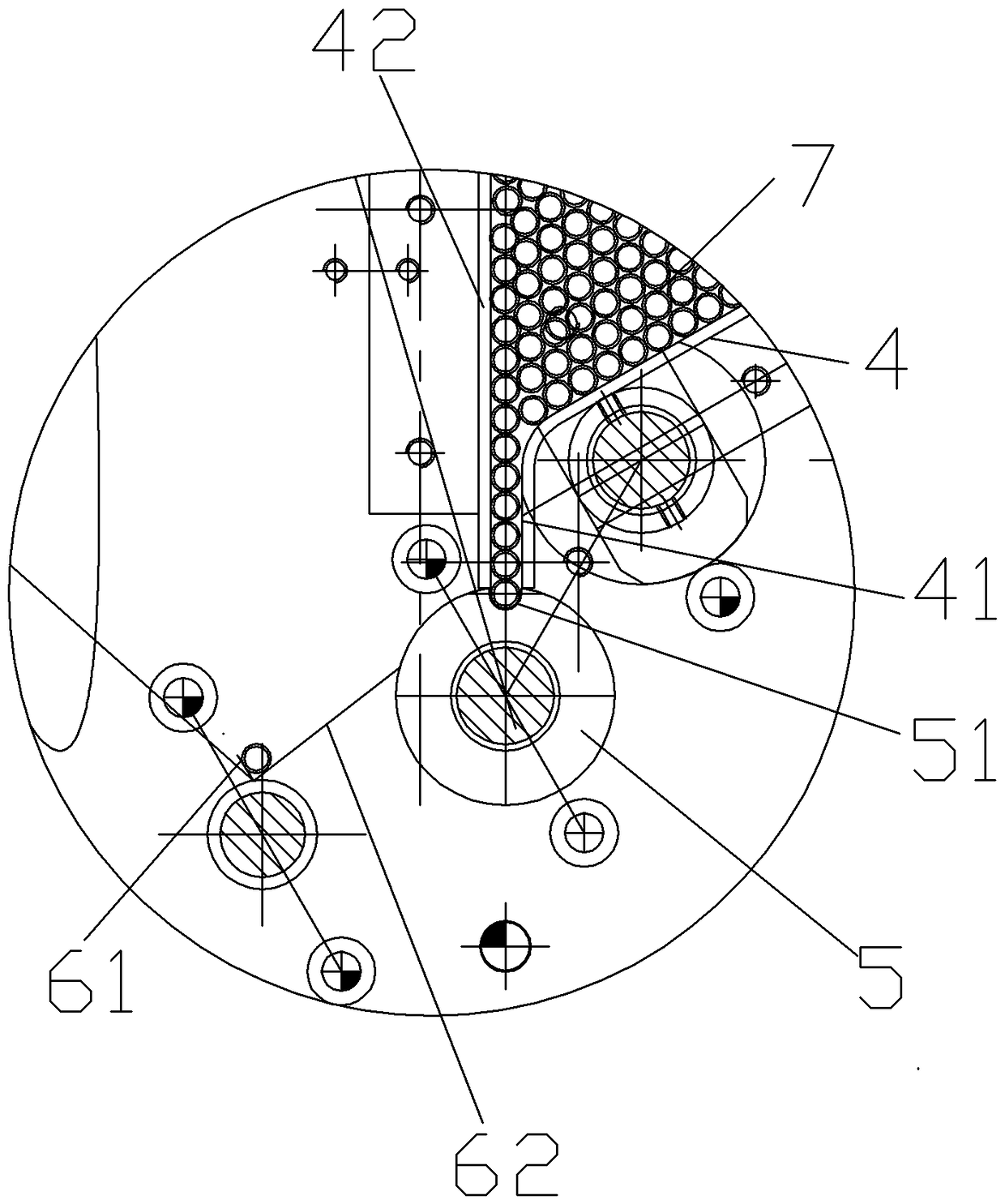

[0027] The thread surface stretching device 100 specifically accepts the thread surface processed by the thread cutting knife 19 in the thread surface cutting mechanism. The thread surface stretching device 100 here specifically includes a bracket 15 extending in the front and rear direction. There are four sets of stretching mechanisms for successively stretching the thread surface to be stretched. Each set of stretching mechanism includes a reversing stretching roller for guiding the thread surface to by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com