A kind of large-area ultra-high molecular weight polyethylene ultra-thin film and preparation method thereof

An ultra-high molecular weight, polyethylene film technology, used in flat products, other household appliances, household appliances, etc., can solve the problems of material waste, high failure rate, time-consuming and laborious process, etc., to reduce the possibility of film rupture, The effect of improving battery energy density and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Heat and boil 475g of vaseline as a solvent and 5g of antioxidant 1010, slowly add 25g of UHMWPE powder at 120°C, and stir evenly to melt and mix the raw materials into a uniform suspension; wherein the content of UHMWPE is 5wt%;

[0056] (2) Transfer the above-mentioned suspension from the beaker to the feeding port of the twin-screw extruder using a siphon tube in the hot state of ultra-high molecular weight polyethylene melting; wherein the inner diameter of the siphon tube is 0.5 ~ 3mm, and the outer diameter is 1~6mm; a uniform gel sheet is obtained by two extrusions, the thickness of the obtained gel sheet is 2mm, and the area is 0.1×0.1 square meters; in the first extrusion, the extrusion temperature is 120-160-180 -220-220-200°C, the second extrusion temperature is 120-160-180-220-220-170°C; the screw speed is 10rpm, and the extrusion rate is 3mm / s;

[0057] (3) The gel sheet obtained by cooling after extrusion to obtain a uniform thickness (thickness is 2mm...

Embodiment 2

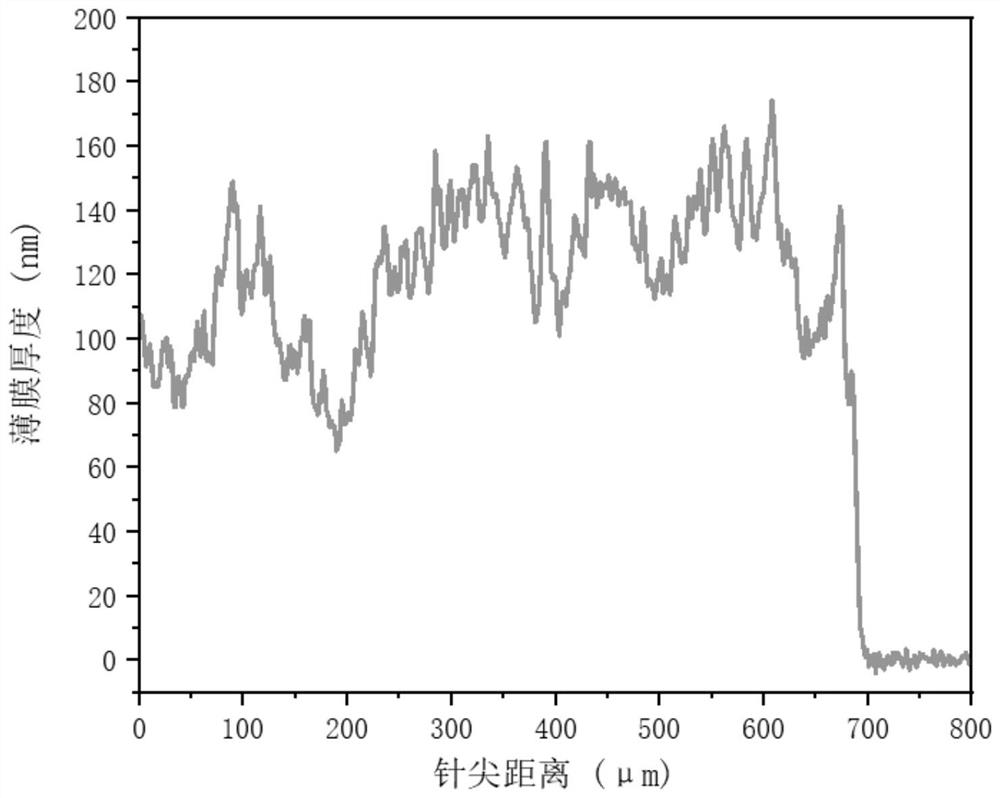

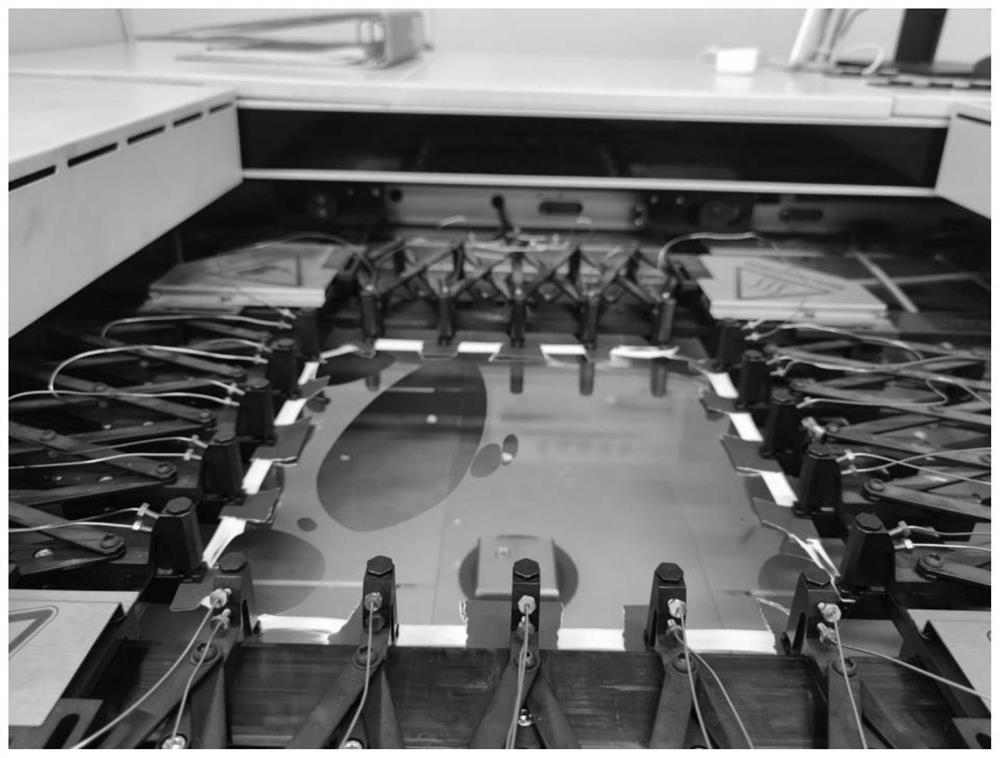

[0061] The other processes are the same as in Example 1, the only difference is that: step 2 of the present invention adopts a single extrusion process, specifically: the extrusion temperature is 160°C, and the extrusion rate is 3mm / s; the gel film after the primary extrusion is subjected to the same After stretching in the stretching process, cracking occurs (such as image 3 shown); It can be seen that large-area ultra-thin films cannot be obtained only through one extrusion.

Embodiment 3

[0071] (1) Heat and boil 485g of yellow vaseline solvent and 5g of antioxidant 1010, slowly add 15g of UHMWPE powder at 120°C, stir evenly to melt the raw materials and pre-mix them into a uniform suspension, wherein the UHMWPE content is 3wt%;

[0072] (2) Add the above-mentioned premixed materials into the internal mixer that has been preheated and is being stirred, the filler content is 80%, the preheating temperature is 120°C, the rotation speed is 20rpm, stir at 120°C for 3 minutes, and then successively stir for 5 minutes Increase the temperature to 160°C, 200°C and 220°C, and stir at the corresponding temperature at 25rpm, 30rpm, and 35rpm for 3min, 5min, and 3min, then lower the temperature to 200°C within 5min, and the stirring rate to 25rpm , stop stirring after stirring for 3 minutes; in the case of slow cooling, the material is taken out from the internal mixer;

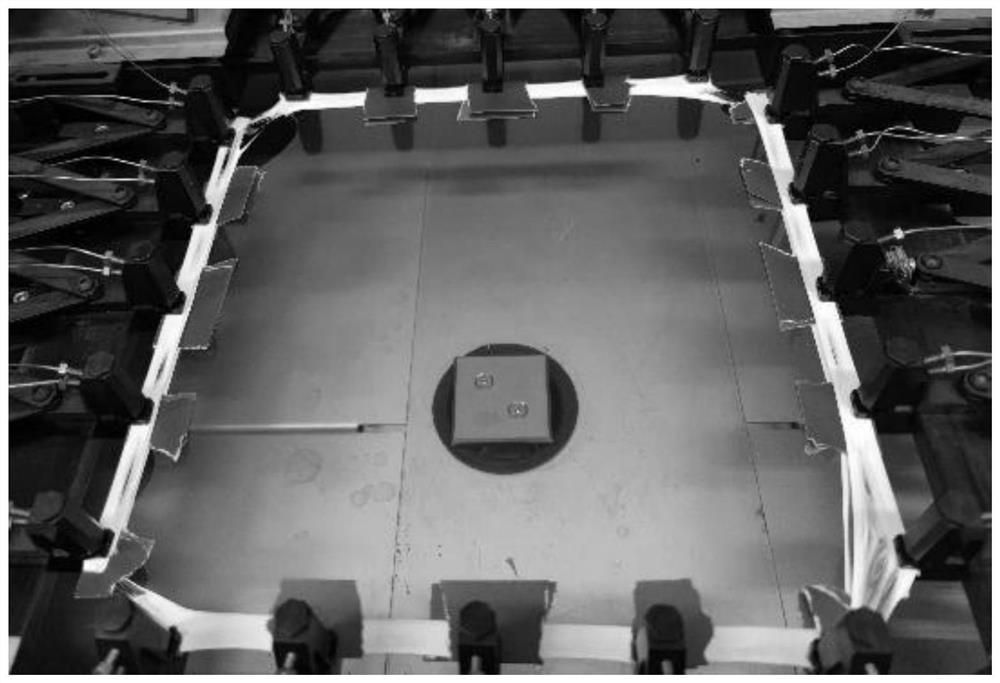

[0073] (3) Put the finished material evenly on the hollow fixture with a thickness of 1mm. The inner f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com